Drilling field monitoring method

An on-site monitoring and on-site technology, applied in earthwork drilling, drilling equipment, drilling automatic control systems, etc., can solve problems such as strong subjectivity, false drilling, and affecting drilling quality, achieve good early warning effects, ensure authenticity, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

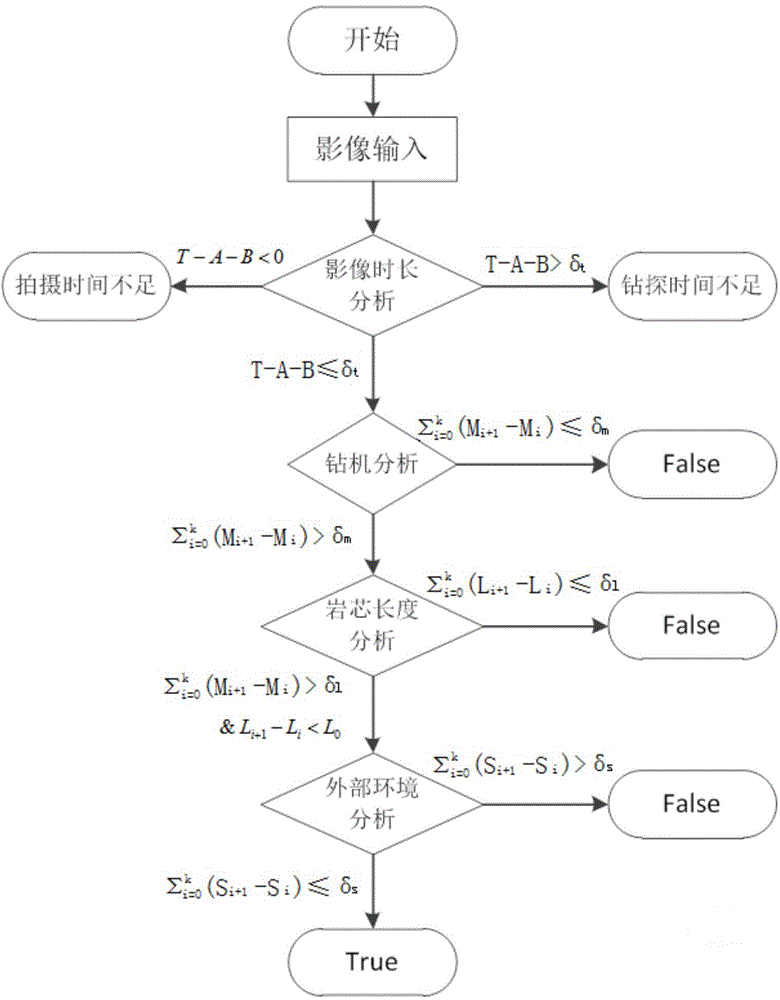

[0029] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further described: a kind of drilling site monitoring method, monitoring is from perforation to end hole, adopts on-the-spot photographing equipment to take the image of drilling site, sends to the image analysis and processing system of background, image analysis The processing system analyzes the drilling results every t hours, and outputs judgment conclusions, so that the quality supervisors can know the situation of the drilling site in time, so as to control the quality of drilling. Wherein, t can be specifically set as required. The specific steps are:

[0030] 1) Image duration analysis: analyze whether the shooting time and drilling time are normal:

[0031] If T-A-B<0, the shooting time is insufficient, and the judgment conclusion that cannot be analyzed is output;

[0032] If T-A-B>δ t , then output the judgment conclusion that the drilling time is insufficient;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com