A wind power generation maximum power tracking method without speed sensor

A maximum power tracking, speed sensorless technology, applied in wind power generation, wind turbine, wind turbine control, etc., to solve measurement problems and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

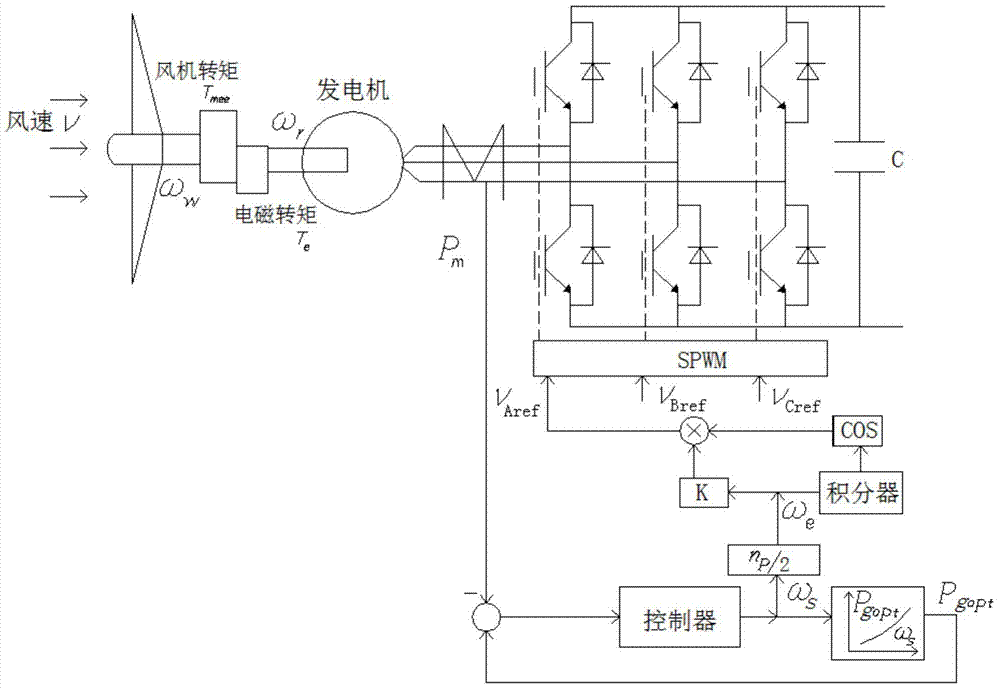

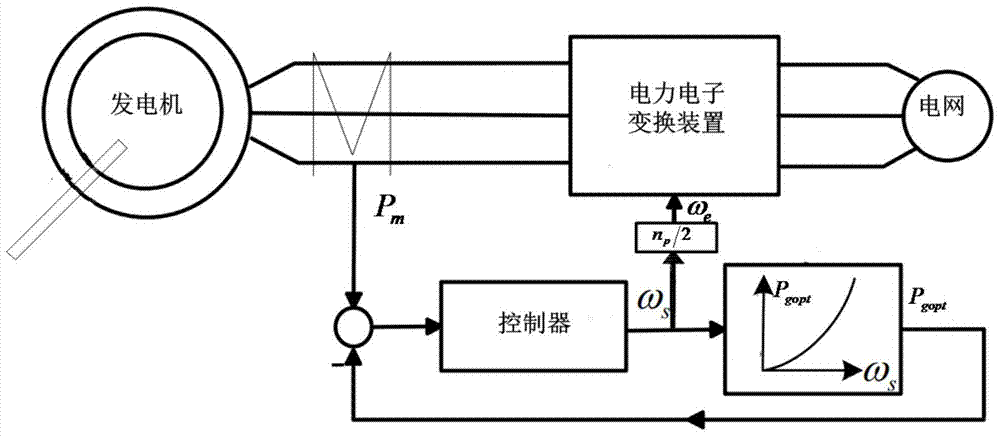

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

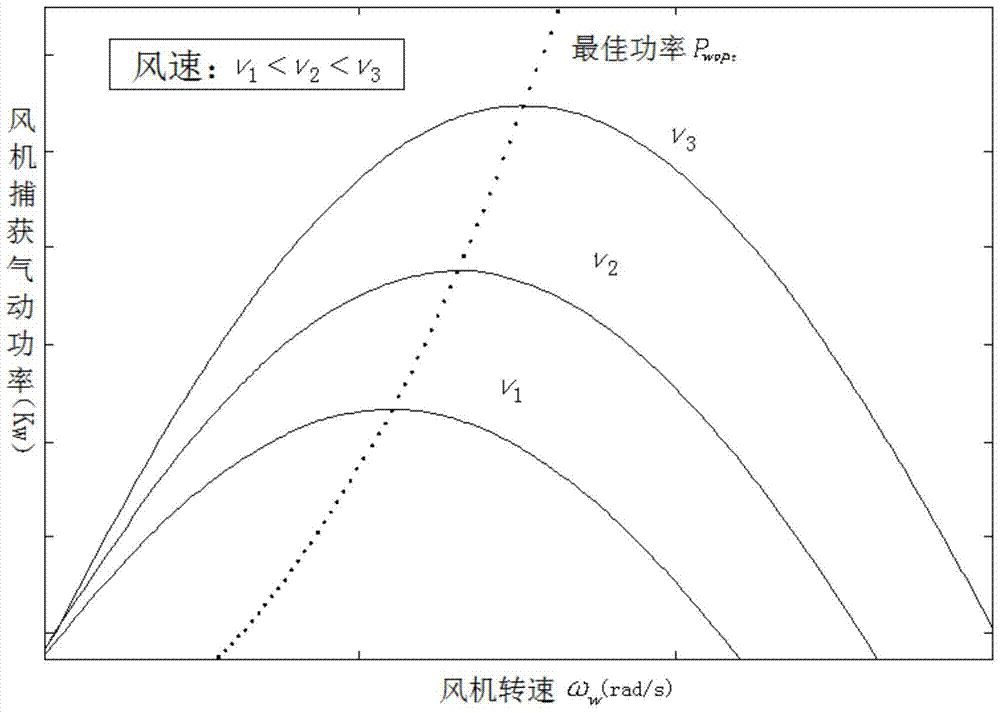

[0044] A wind power generation maximum power tracking method without a speed sensor, its principle is as follows figure 1 As shown, the method includes the following steps:

[0045] 1) Obtain the relationship curve between the maximum wind energy capture and the motor speed through experiments:

[0046] According to the aerodynamic theory, the aerodynamic power captured by the wind wheel can be expressed as

[0047]

[0048] In the formula: ρ is the air density; R is the impeller rotation plane radius; C p(λ, β) is the wind energy utilization coefficient of the wind turbine; β is the pitch angle; ν is the wind speed; λ=ω w R / ν is the tip speed ratio, ω w is the angular velocity of the fan. In the maximum power tracking stage, generally only the fan speed is adjusted, while the pitch angle remains unchanged. The purpose of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com