A self-priming centrifugal pump

A self-priming centrifugal pump and centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of low self-priming efficiency of centrifugal pumps, poor gas-liquid separation effect, slow water feeding speed, etc. The effect of accelerating gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

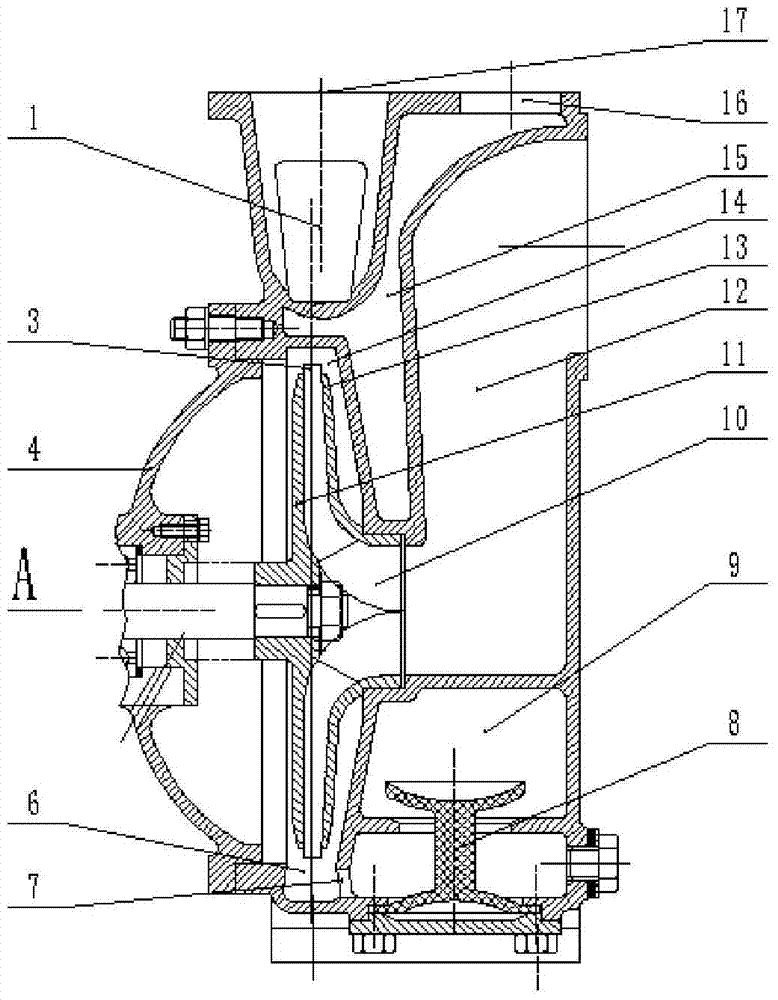

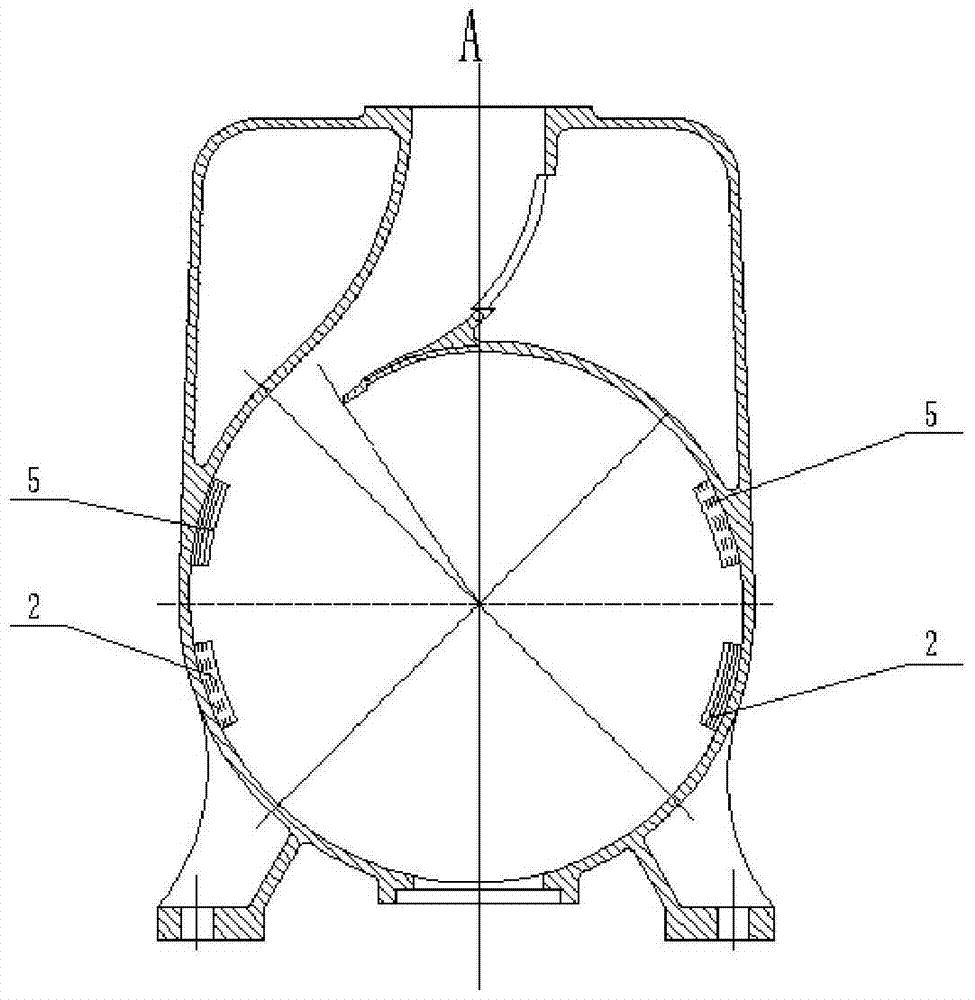

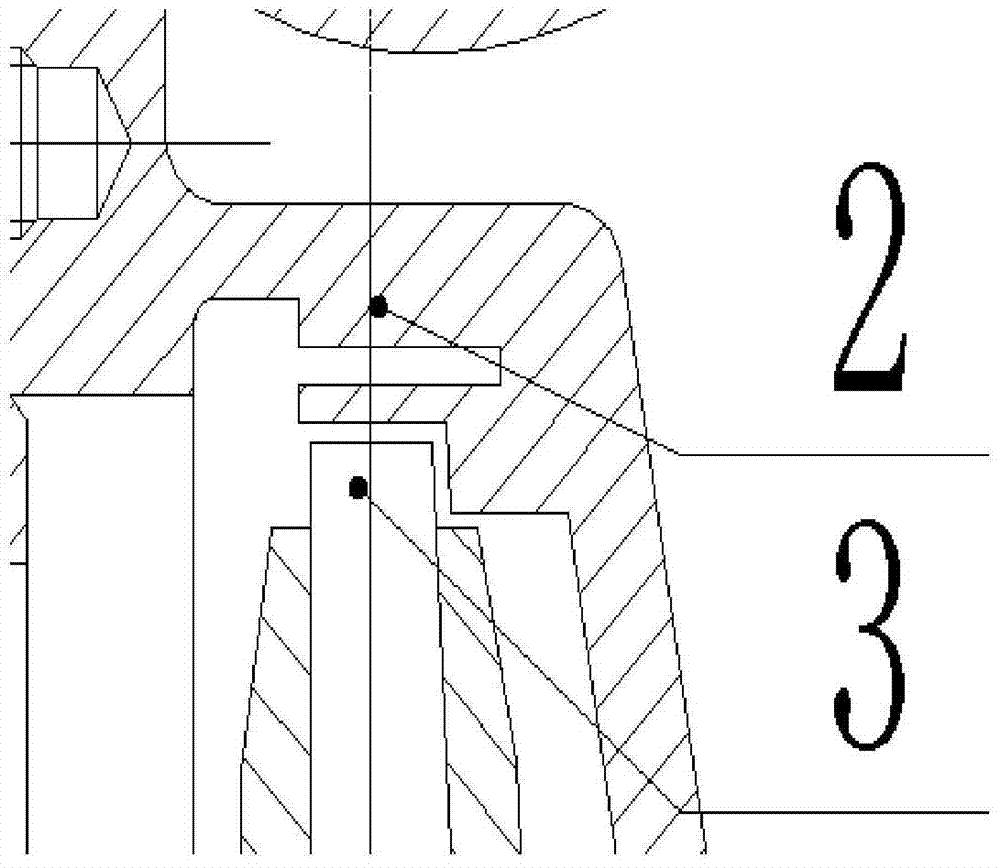

[0024] Reference attached figure 1 , the centrifugal pump includes a pump body and a volute, the volute is located inside the centrifugal pump body, and the volute is provided with a volute water outlet 17, an inlet 1 of the gas-liquid separation chamber, and a return hole 7; the inside of the centrifugal pump body An S-shaped elbow 12 is also provided, and the S-shaped elbow 12 communicates with the impeller inlet 10; the inner cavity of the volute forms the vortex chamber 6 of the self-priming centrifugal pump, and the impeller 3 is also arranged in the vortex chamber 6; The impeller 3 is fixed on the pump shaft through the impeller front cover 13 and the impeller rear cover 11; the volute also includes a front F-shaped sector partition 2 and a rear F-shaped sector partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com