Quantum dot packaging tube clamping device, backlight module and liquid crystal display device

A technology of clamping device and backlight module, which is applied to lighting devices, point light sources, components of lighting devices, etc. Improve efficiency, avoid yellowing, enhance heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

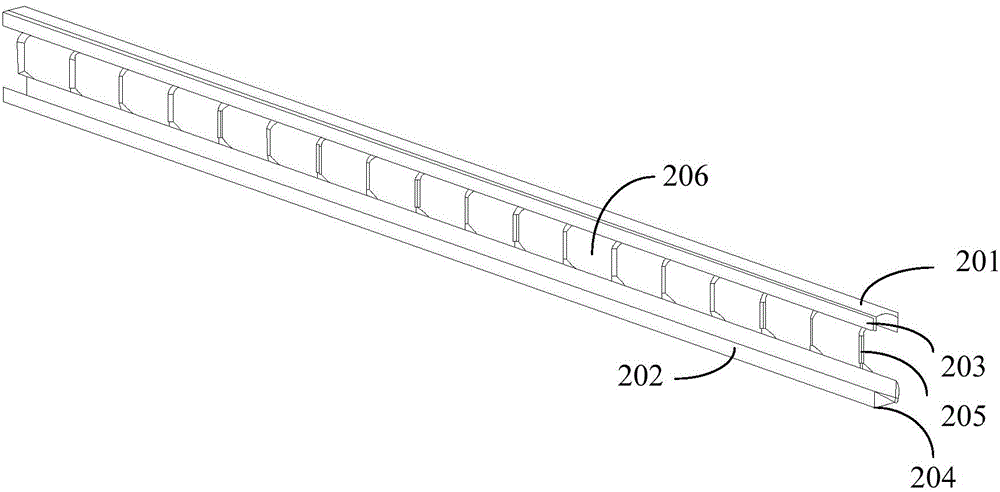

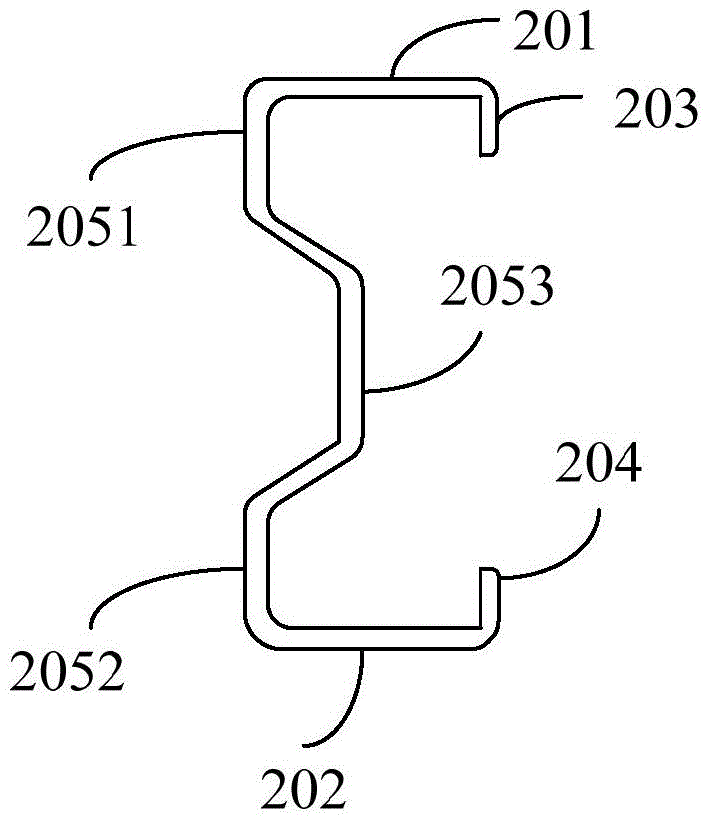

[0030] refer to figure 2 and image 3 , figure 2 It is a schematic diagram of the three-dimensional structure of an embodiment of the quantum dot packaging tube clamping device of the present invention, image 3 yes figure 2 A schematic side view of an embodiment of a clamping device for a medium quantum dot packaging tube.

[0031] Such as figure 2 and image 3 As shown, the quantum dot packaging tube clamping device of this embodiment includes a first outer edge 201 and a second outer edge 202 arranged in parallel, a first card edge 203 vertically arranged on the first outer edge, and a vertical vertical edge on the second outer edge. The second card edge 204 is set. Between the first outer edge 201 and the second outer edge 202, there are also a plurality of spacer connectors 205 arranged at intervals in parallel, wherein, as image 3 As shown, the spacer connector 205 includes a connecting portion 2051 connected to the first outer edge 201 , a connecting portion...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap