Burner of aircraft fire protection testing apparatus

A test device and burner technology, applied in the field of aviation test, can solve problems such as poor flame temperature uniformity of the burner, poor flame temperature uniformity of the burner, failure to meet standard requirements, etc., to increase flame temperature uniformity, flame Effect of temperature uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

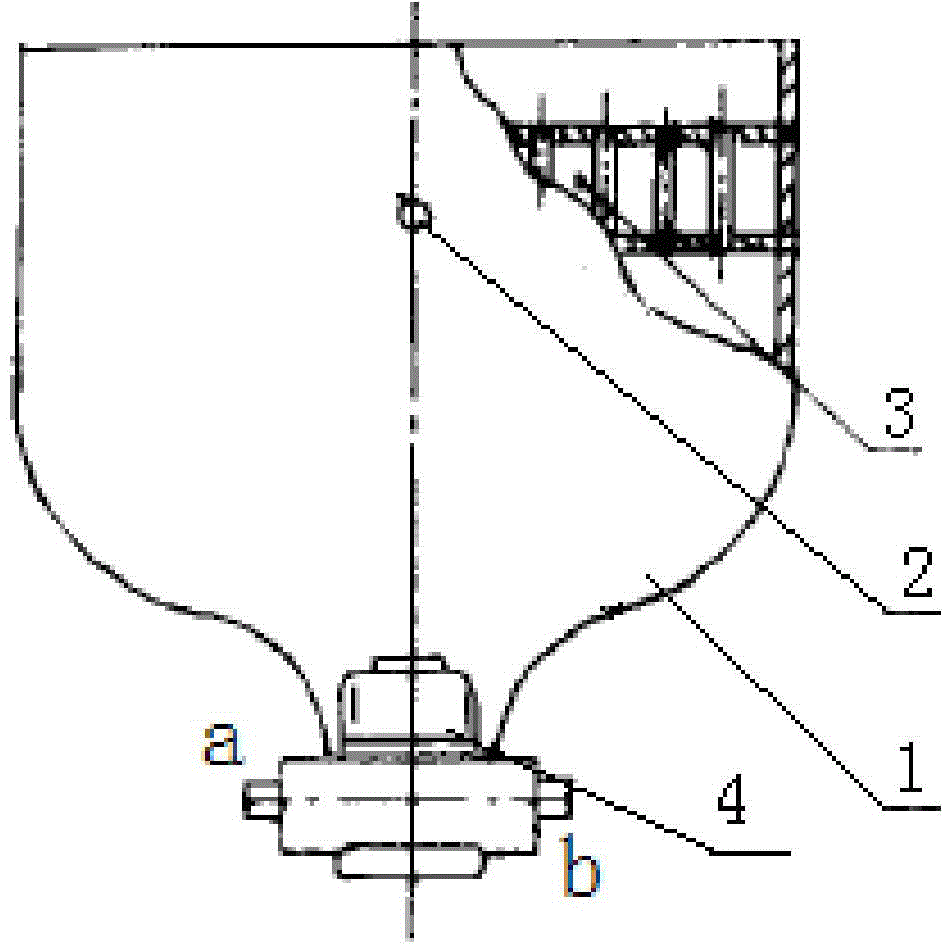

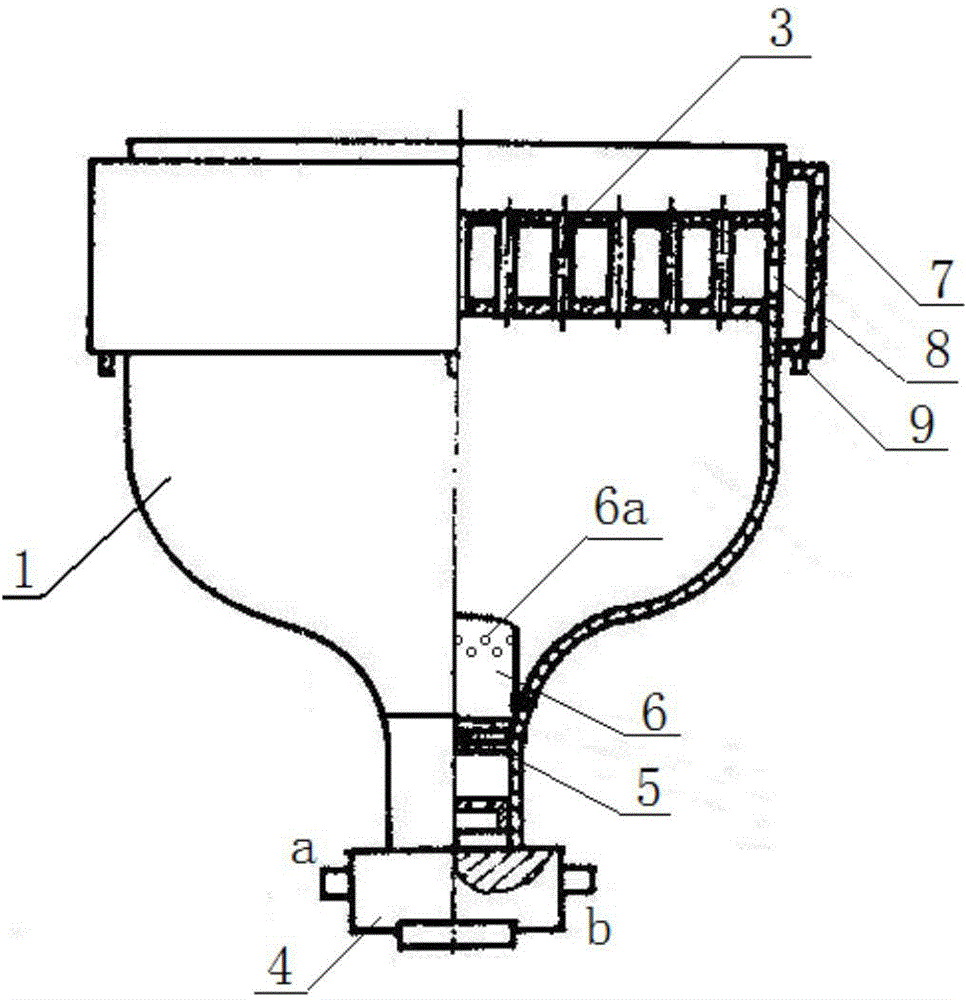

[0008] The present invention will be described in further detail below. see figure 2 , a burner of an aircraft fire test device, comprising a housing 1, a combustion chamber 3 and a mixing base 4; the housing 1 has a bowl-shaped profile, and the outer diameter of the upper port of the housing 1 is greater than that of the lower port; The upper port of the body 1 is smoothly transitioned to the lower port, the combustion chamber 3 is welded in the upper port of the housing 1, the mixing base 4 and the lower port of the housing 1 are welded as a whole or are integrally connected by threads, and the mixing base 4 has The gas inlet 4a and the compressed air inlet 4b, the air outlet of the mixing base 4 are located in the lower port of the housing 1; it is characterized in that there is a mixing net assembly on the lower port of the housing 1 and above the air outlet of the mixing base 4 5. The mixed mesh assembly 5 is composed of 2 to 6 layers of mixed mesh stacks. The mesh size...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap