Wide-angle lens

A wide-angle lens, negative lens technology, applied in the field of wide-angle lens, can solve problems such as initial investment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

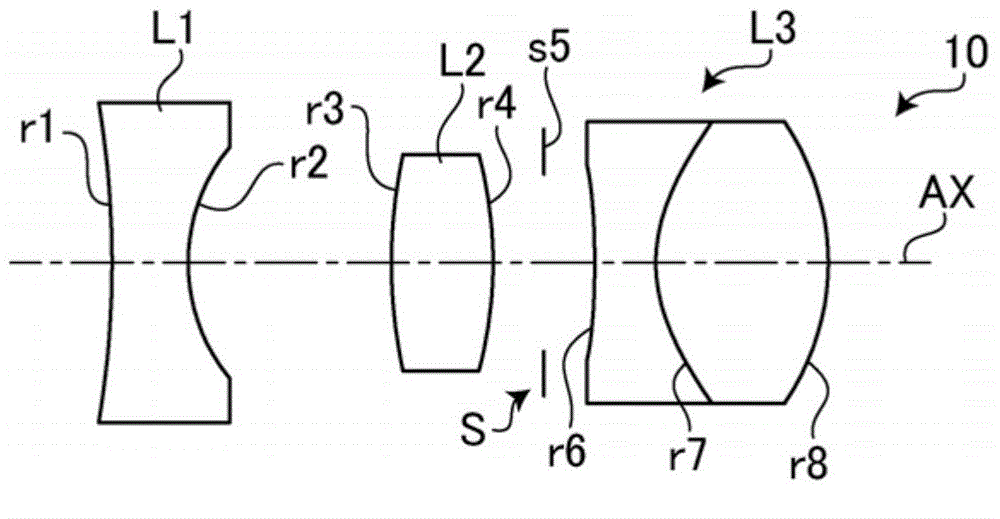

[0144] As described above, the structure of the wide-angle lens 10 of Embodiment 1 of the present invention is as follows figure 1 shown. In the present Example 1, the negative lens group is composed of a negative lens L1 made of glass. The cemented lens L3 has a structure in which a negative lens and a positive lens are arranged from the object side.

[0145] Table 1 shows specific numerical values (surface data, aspheric surface data, and various data) of the wide-angle lens 10 of the first embodiment. The numbers NO and figure 1 The surface symbol rn (n is a natural number) and the aperture symbol sn correspond to each other. "*" added to the number NO in Table 1 (surface data) indicates that the surface corresponding to the number NO is an aspherical surface. In Table 1 (surface data), R (unit: mm) indicates the radius of curvature of each surface of the optical component, D (unit: mm) indicates the thickness of the optical component or the distance between optical c...

Embodiment 2

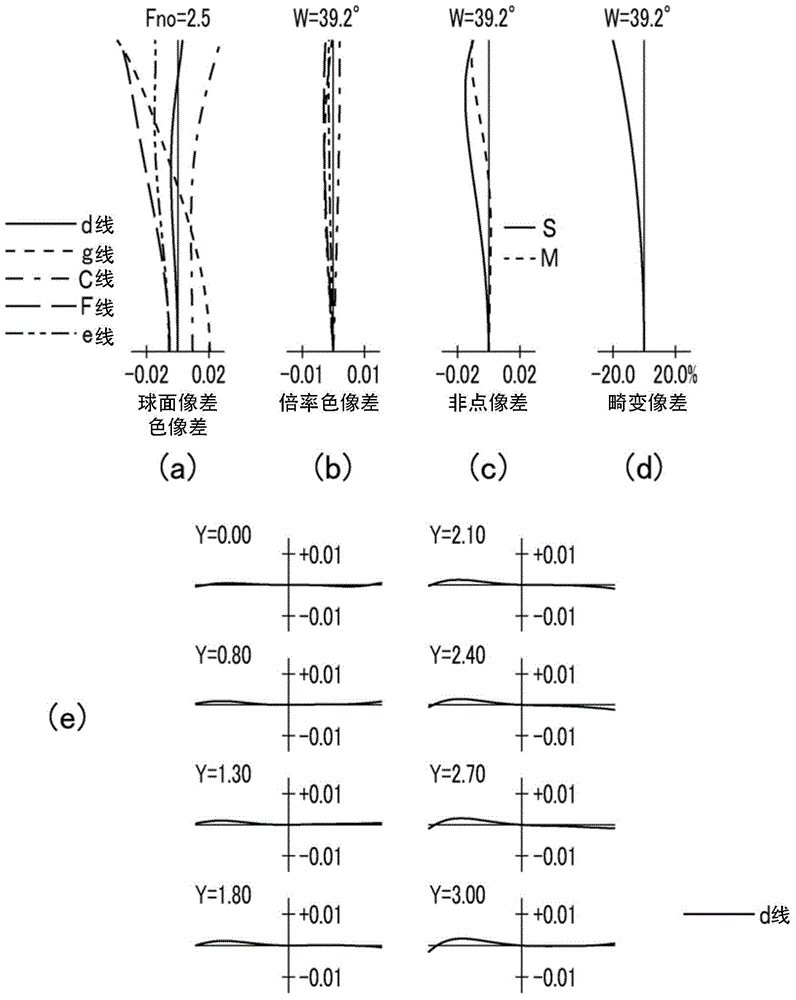

[0152] image 3 It is a layout diagram showing the structure of the wide-angle lens 10 according to the second embodiment of the present invention. In Example 2, the negative lens group is composed of a negative lens L1 made of resin. The cemented lens L3 has a structure in which a positive lens and a negative lens are arranged from the object side. Figure 4 (a) to (e) are diagrams of various aberrations (spherical aberration, axial chromatic aberration, lateral chromatic aberration, astigmatism, distortion aberration, lateral aberration) of the wide-angle lens 10 of the second embodiment . Table 2 shows the specific numerical configuration (surface data, aspheric surface data, various data) of the wide-angle lens 10 of the second embodiment.

[0153] 【Table 2】

[0154] Example 2

[0155]

Embodiment 3

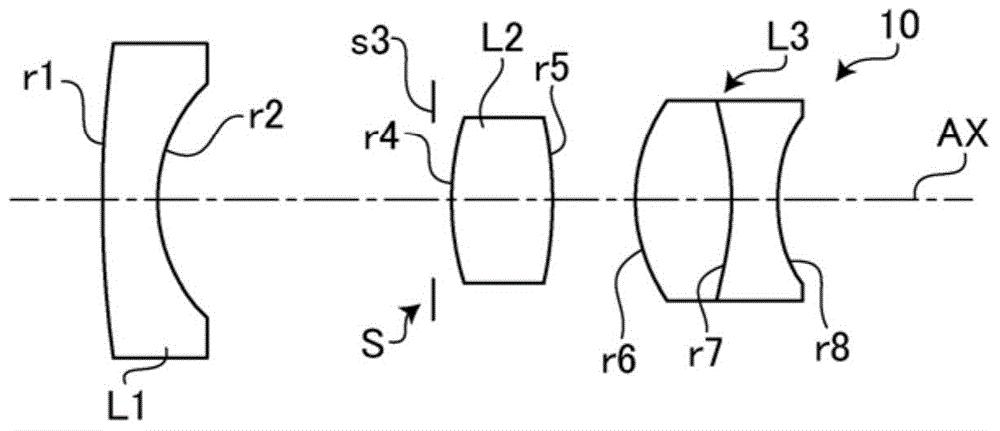

[0157] Figure 5 It is a lens arrangement diagram showing the structure of the wide-angle lens 10 according to the third embodiment of the present invention. In the third embodiment, the negative lens group is composed of a negative lens L1 made of resin. The cemented lens L3 has a structure in which a positive lens and a negative lens are arranged from the object side. Figure 6 (a) to (e) are diagrams of various aberrations (spherical aberration, axial chromatic aberration, lateral chromatic aberration, astigmatism, distortion aberration, lateral aberration) of the wide-angle lens 10 of the third embodiment . Table 3 shows the specific numerical configuration (surface data, aspheric surface data, various data) of the wide-angle lens 10 of the third embodiment.

[0158] 【table 3】

[0159] Example 3

[0160]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com