Noise optimization method for engine intake system

A technology of air intake system and optimization method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of low cost, high cost, and low efficiency, and achieve low cost, high optimization efficiency, and solution less efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

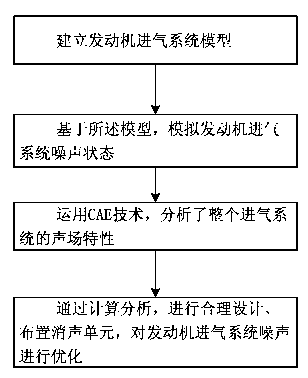

[0024] In Embodiment 1, a noise optimization method for the engine air intake system is provided, please refer to figure 1 , the method includes:

[0025] Step 1: Establish a model of the engine intake system;

[0026] Step 2: Based on the model, simulate the noise state of the engine intake system;

[0027] Step 3: Use CAE technology to analyze the sound field characteristics of the entire intake system;

[0028] Step 4: Through calculation and analysis, rationally design and arrange the muffler unit, and optimize the noise of the engine intake system.

[0029] Wherein, in the embodiment of the present application, the intake system noise is specifically divided into: air noise and structure noise.

[0030] Among them, in the embodiment of the present application, the air intake system of the engine is a very complex noise source, including various types of noises, and the mechanism of each noise is different. Therefore, to optimize the noise of the intake system, it is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com