Image thinning and characteristic classification method used for product defect detection and quality control

A product defect and feature classification technology, applied in image analysis, image data processing, character and pattern recognition, etc., can solve problems such as circle thinning into points, algorithm time-consuming cannot exceed, thinning unevenness, etc., to ensure correctness performance, eliminating the effect of endpoint interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing:

[0051] The directional terms mentioned in the following embodiments, such as "up, down, left, right" are only referring to the directions of the drawings, therefore, the directional terms are used for illustration and not for limiting the present invention.

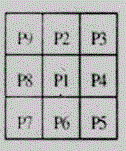

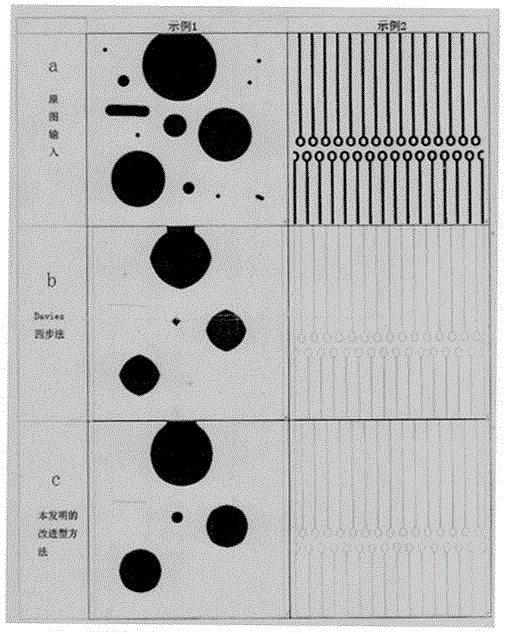

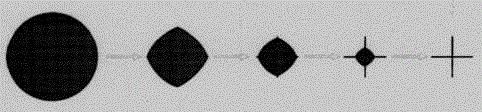

[0052] This method is an improved method by improving the four-step method of Dayies. The general four-step method of Dayies is first introduced below. This method continuously iterates and thins the image in four steps from top, bottom, left and right: 1. It introduces the concept of crossover number χ (combined with Figure 4 ):

[0053] χ=(b 2 ! =b 4 )+(b 4 ! =b 8 )+(b 8 ! =b 6 )+(b 6 ! =b 2 )+2*((~b 2 &b 1 &~b 4 )+(~b 2 &b 3 &~b 6 )+(~b 4 &b 7 &~b 8 )+(~b 8 &b 9 &~b6 ))

[0054] 2. Neighborhood sum: σ=b1+b2+b3+b4+b6+b7+b8+b9

[0055] 3. Define north, south, east, west points, take the nort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com