Electrical discharge unit and air cleaner

An air purifier and discharge unit technology, applied in the direction of air quality improvement, chemical instruments and methods, power supply technology, etc., to achieve the effect of miniaturization and suppression of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

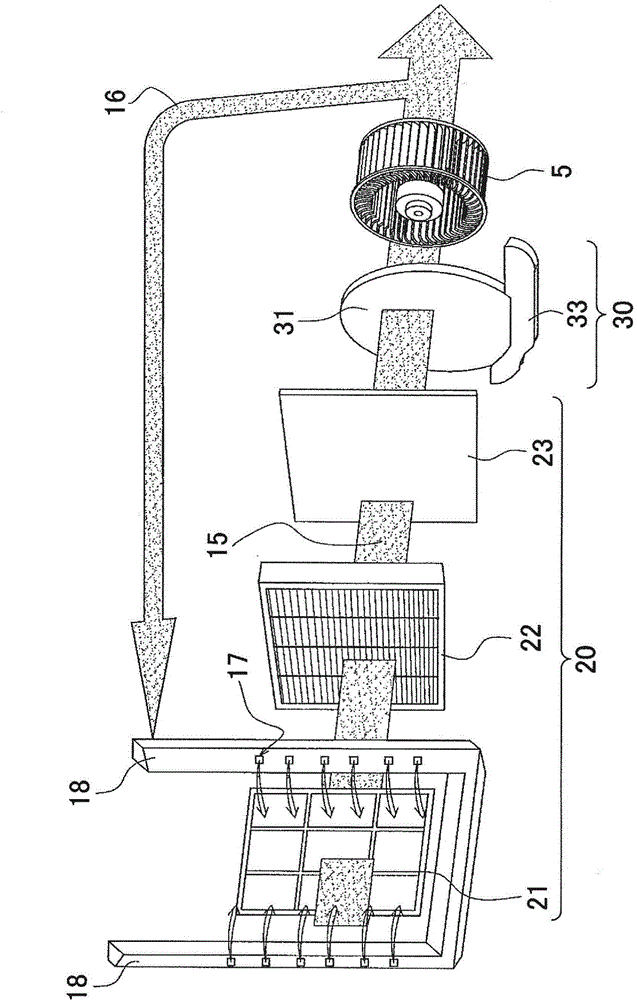

[0060] Embodiments of the present invention will be described below with reference to the drawings.

[0061] [structure of air cleaner 1]

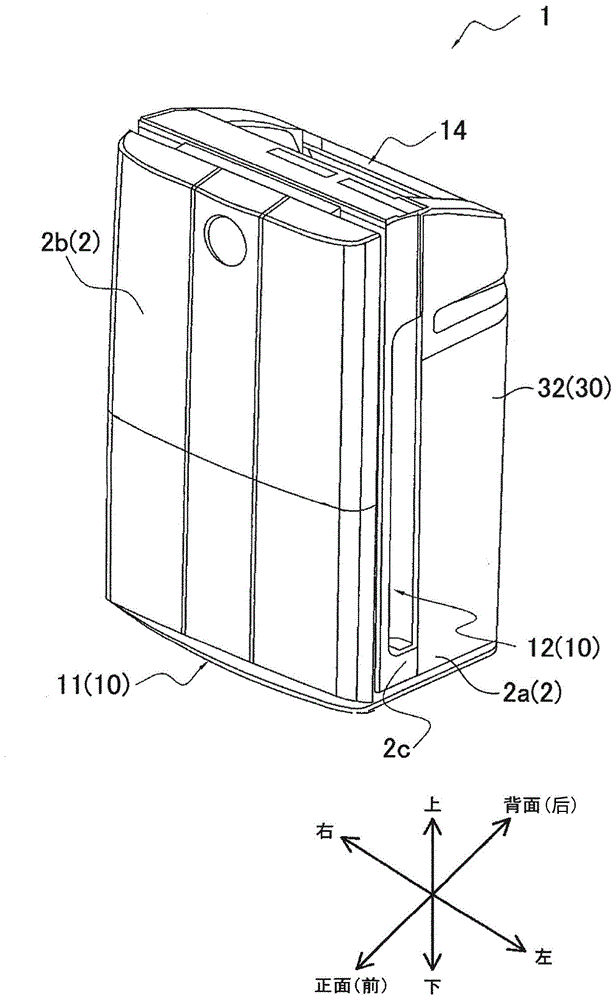

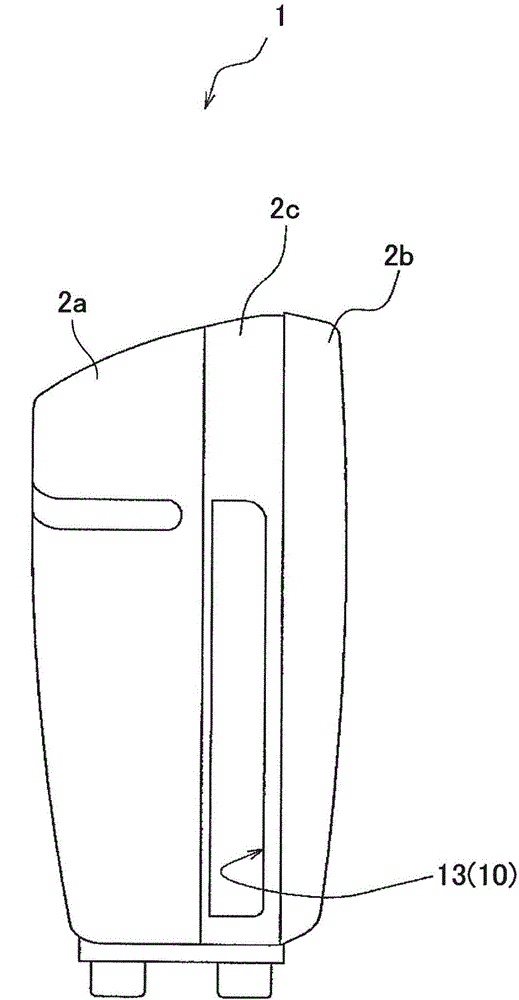

[0062] The air purifier 1 of the embodiment of the present invention is as Figure 1 ~ Figure 4 As shown, it has: a housing 2 composed of a main body housing 2a and a front panel 2b, an electrical dust collector 3 (discharging unit), a streamer discharge unit (Japanese: ストリーマラニット4, a fan 5, a filter unit 20, a humidifier Unit 30 etc.

[0063] Such as figure 1 As shown, the front of the air cleaner 1 is covered by a front panel 2b. There is a part not covered by the front panel 2b below the front, and the lower suction port 11 is provided in this part. Such as figure 1 and figure 2 As shown, a part of the side surface of the air cleaner 1 is covered with a part of the main body case 2a, that is, a side inlet forming member 2c made of synthetic resin. The first side suction port 12 for sucking in air is formed in the side suction por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com