Conductive adhesive type resurrection-preventing radio frequency tag and manufacturing method thereof

A technology of radio frequency tags and manufacturing methods, applied in anti-theft alarms, thin film/thick film capacitors, instruments, etc., can solve the problems of difficult operation and high scrap rate, and achieve the effects of easy manufacturing, thorough short circuit, and good anti-resurrection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

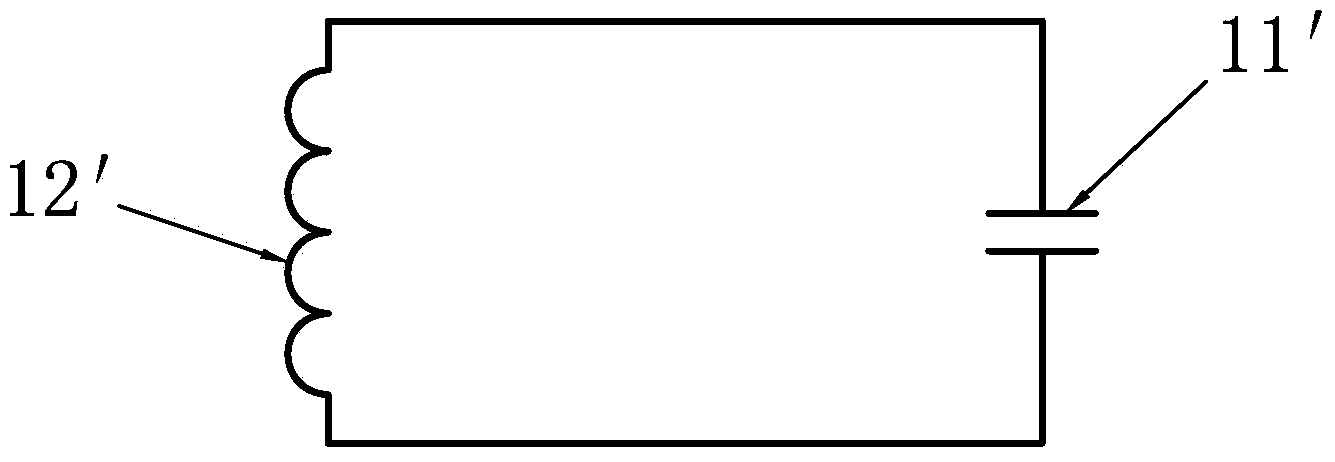

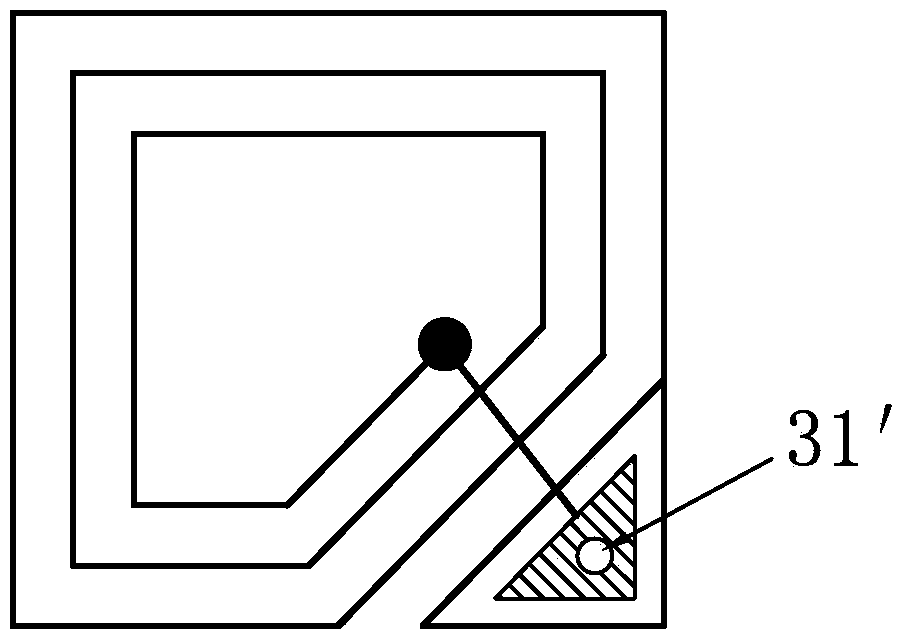

[0036] like Figure 8 As shown, the first embodiment of the conductive adhesive type anti-reactivation radio frequency tag of the present invention includes a capacitor plate 1 and a second capacitor plate 5, a dielectric layer 4 is arranged between the capacitor plate 1 and the second capacitor plate 5, and the capacitor A decoding point 2 is provided on the pole plate 1, and a conductive glue 3 is cured on the surface of the pole plate inside the decoding point 2 and on the periphery of the decoding point 2. The curing temperature of the conductive adhesive 3 in this embodiment is 130°C.

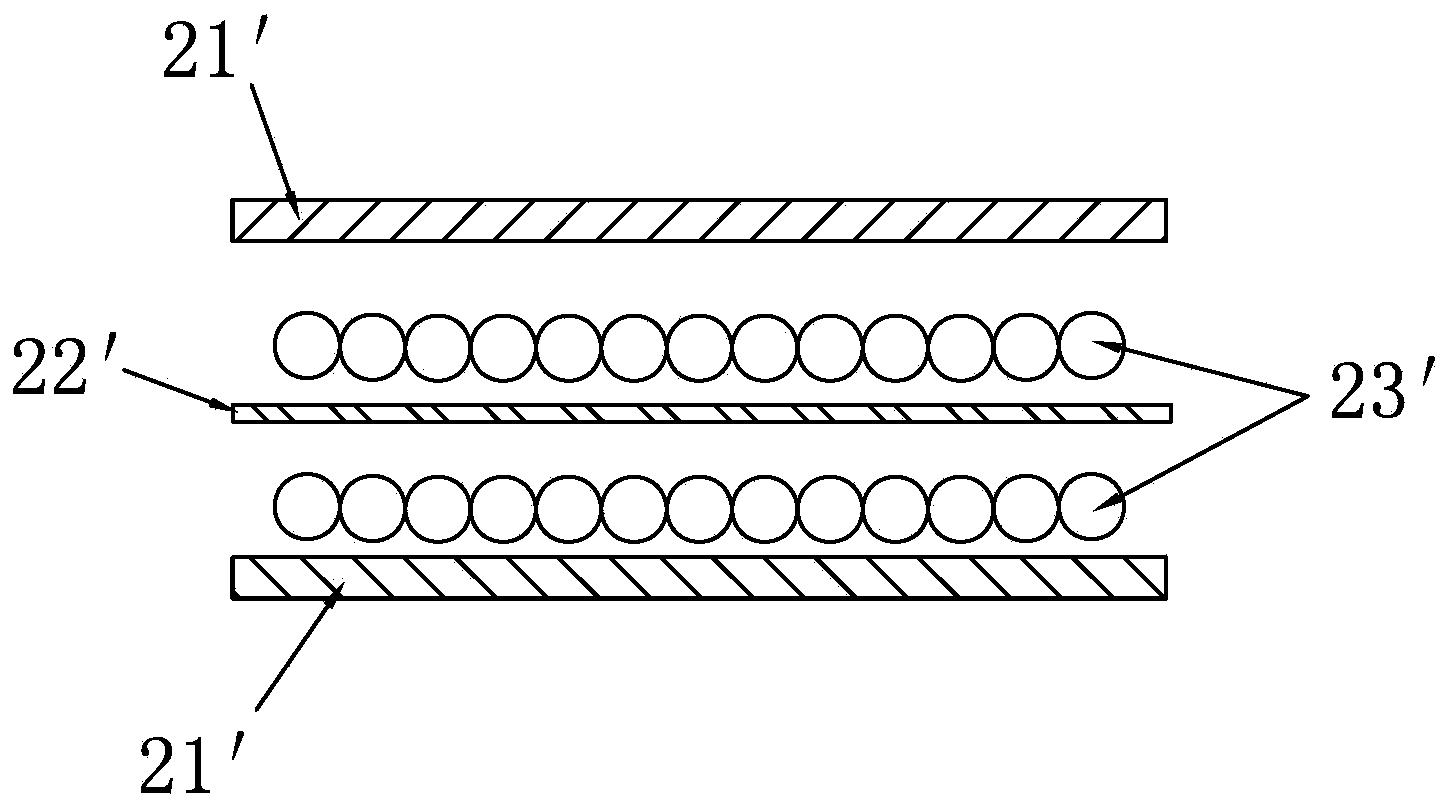

[0037] During the manufacture of this embodiment, the radio frequency tag circuit is manufactured by using the existing process first, that is: using the adhesive method to compound the insulating film layer and the conductive layer; adopting a conventional method to coat the circuit on the conductive layer; The circuit is etched to obtain the circuit; then the micro-concave surface is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com