Modular weeding device

A modular and weed-based technology, applied in character and pattern recognition, biological neural network models, image data processing, etc., can solve the problems that weeding equipment cannot be contoured, reduces the weed removal efficiency of weeding equipment, and is not suitable for weeding work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

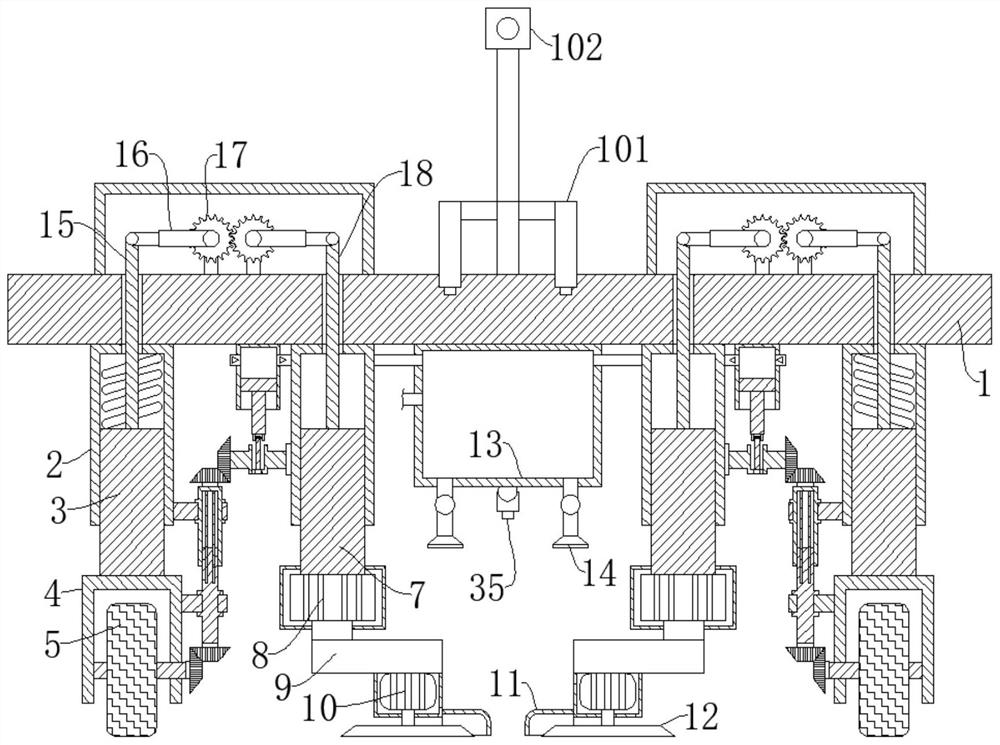

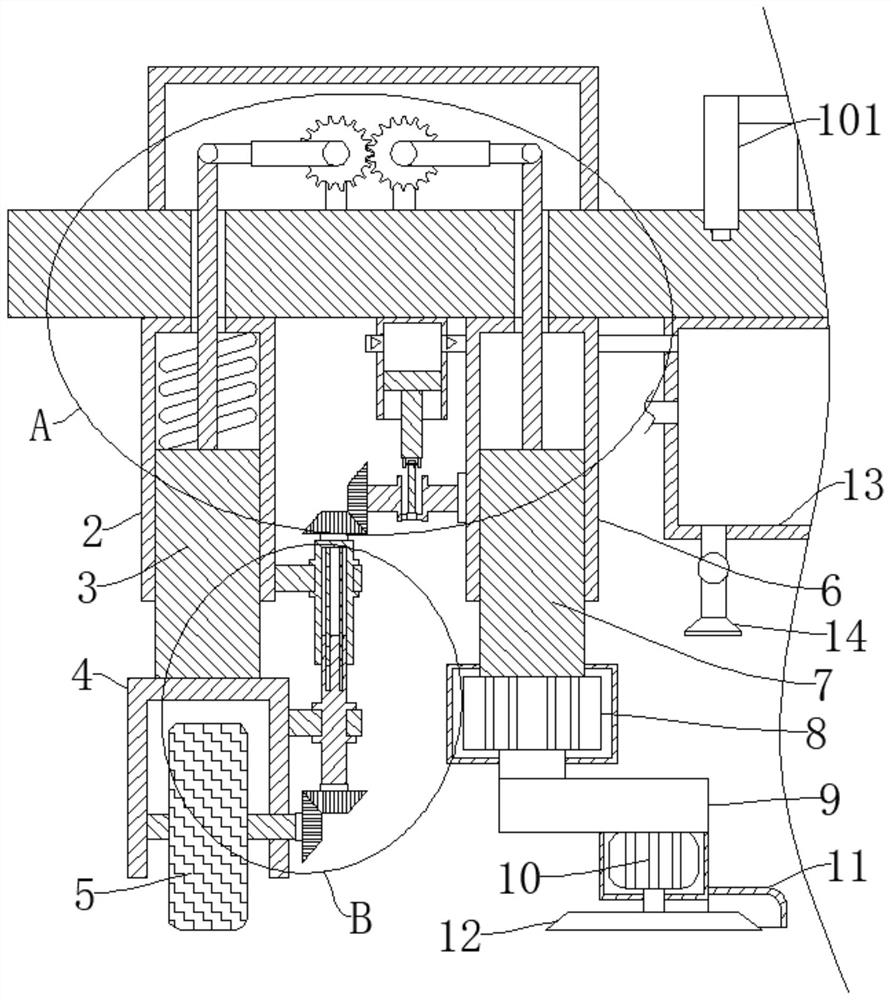

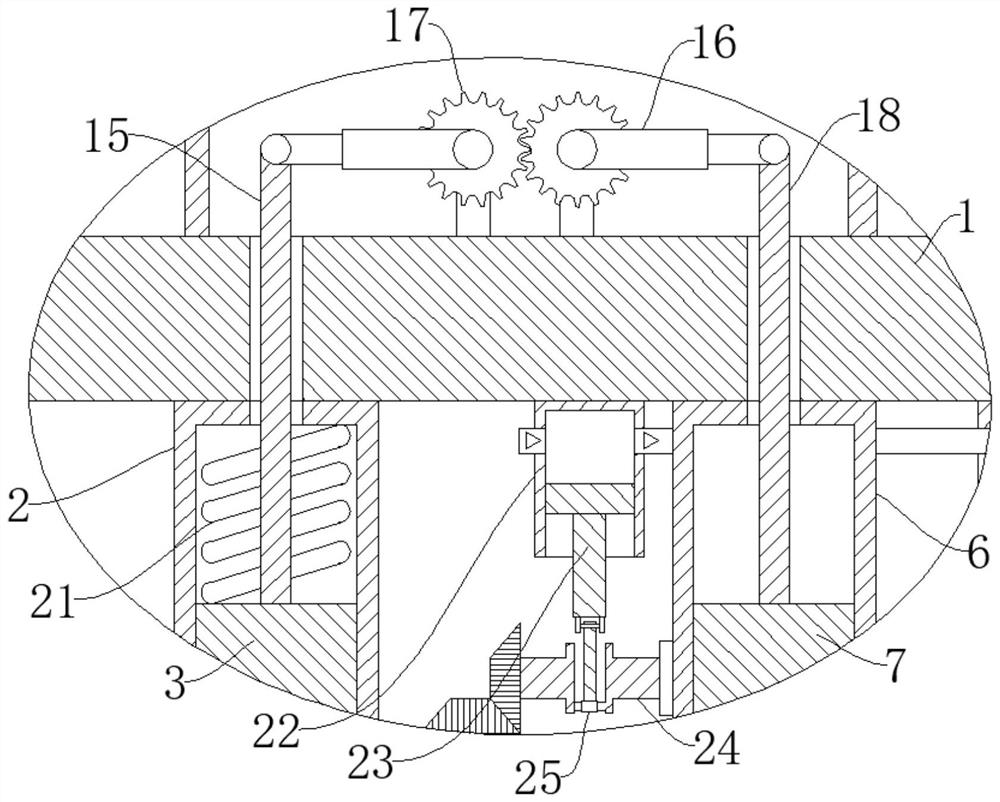

[0054] refer to Figure 1-9 , a modular weeding device, comprising a fixed platform 1, two symmetrical first sleeves 2 are fixedly connected to the lower end of the fixed platform 1, and a telescopic spring 21 is fixedly connected to the first sleeve 2, and the first sleeve 2 The first moving column 3 is slidingly connected inside, and the upper end of the first moving column 3 is fixedly connected with the telescopic spring 21. The lower end of the first moving column 3 is connected with a connecting frame 4, and the connecting frame 4 is connected with a rotating shaft 31 through a rotating shaft. The runner 5 is provided with two symmetrical second sleeves 6 between the two first sleeves 2, the second sleeves 6 are fixedly connected with the fixed table 1, and the second sleeve 6 is slidingly connected with a second movable Column 7, the lower end of the second mobile column 7 is connected with a weeding mechanism, the weeding end of the weeding mechanism is at the same hei...

Embodiment 2

[0059] refer to figure 1 , figure 2 and Figure 5 , a modular weeding device, which is basically the same as Embodiment 1, furthermore: the weeding mechanism includes a first motor 8, a rotating rod 9, a second motor 10, and a weeding plate 12, and the first motor 8 is fixedly connected to the second The lower end of the moving column 7, the rotating rod 9 is fixedly connected to the output end of the first motor 8, the end of the rotating rod 9 away from the first motor 8 is fixedly connected to the second motor 10, and the weeding plate 12 is fixedly connected to the output of the second motor 10 At the end, when the first weed recognition camera 101 detects the position of the weeds, at this time, the main controller 104 controls the first motor 8 and the second motor 10 to rotate, so as to achieve precise weeding without removing the weeds. crops, effectively improving the practicability of the device.

Embodiment 3

[0061] refer to Figure 5, a modular weeding device, which is basically the same as Embodiment 1, furthermore: the first motor 8 and the second motor 10 are sleeved with a first protective cover, and the first protective cover close to the second motor 10 The protective plate 11 that is fixedly connected with the weeding plate 12 is matched, and by the setting of the first protective cover, the first motor 8 and the second motor 10 can be played a dust-proof effect. 12 When weeding, grass clippings will not fly around.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com