Temperature-controllable heating element, atomizer and electronic cigarette

A technology for heating components and heating parts, applied in the field of electronic cigarettes, can solve problems such as affecting the user's taste experience, damage to heating components, dry burning, etc., and achieve the effects of convenient assembly, prevention of electric leakage, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

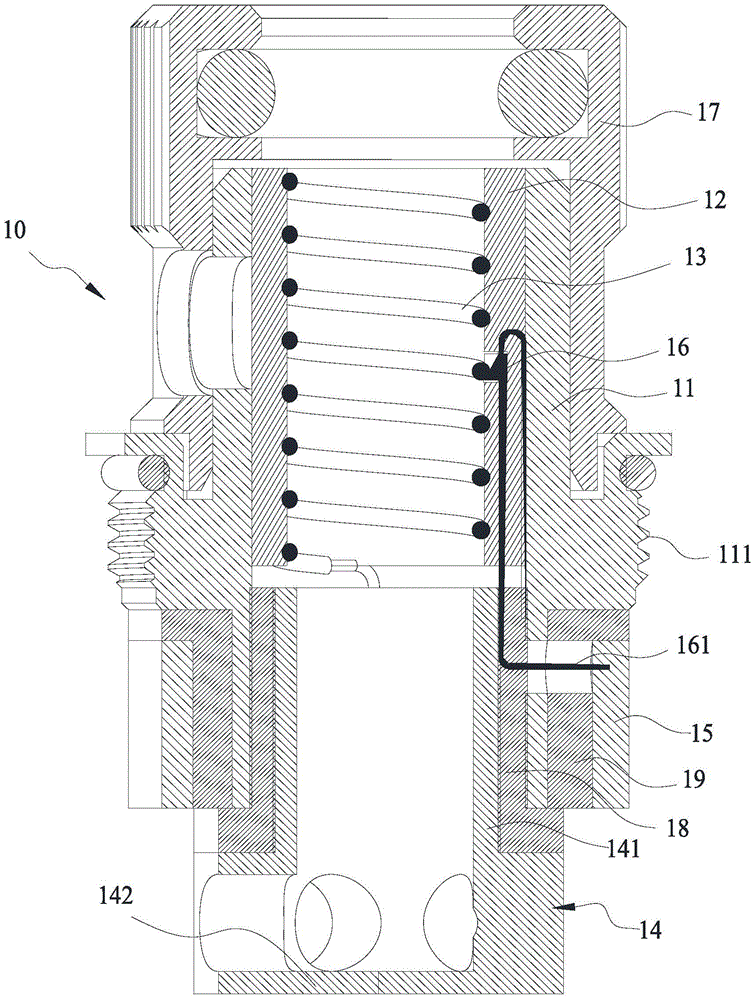

[0029] Such as figure 1 The temperature-controllable heating component 10 shown includes a conductive fixing seat 11, a liquid-conducting medium layer 12, a heating element 13, a first positive electrode contact 14, a positive electrode ring 15, and a temperature sensing device 16. The liquid-conducting medium layer 12 is attached On the inner wall of the conductive fixing seat 11, the heating element 13 and the temperature sensing device 16 are built in the liquid conducting medium layer 12, and the temperature sensing device 16 is close to the heating element 13 or arranged in the liquid conducting medium layer 12 near the heating area of the heating element 13 , the negative pole of the heating element and the negative pole of the temperature sensing device 16 are electrically connected to the conductive holder 11; the first positive contact 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com