Centralized column supply management unit and system based on four-quadrant control

A management unit and centralized technology, applied in the field of rail transit, can solve the problems of train power supply fluctuation, the train supply cabinet does not have a train supply management unit, and the train supply cabinet cannot be accurately controlled, so as to achieve the effect of safe and reliable power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

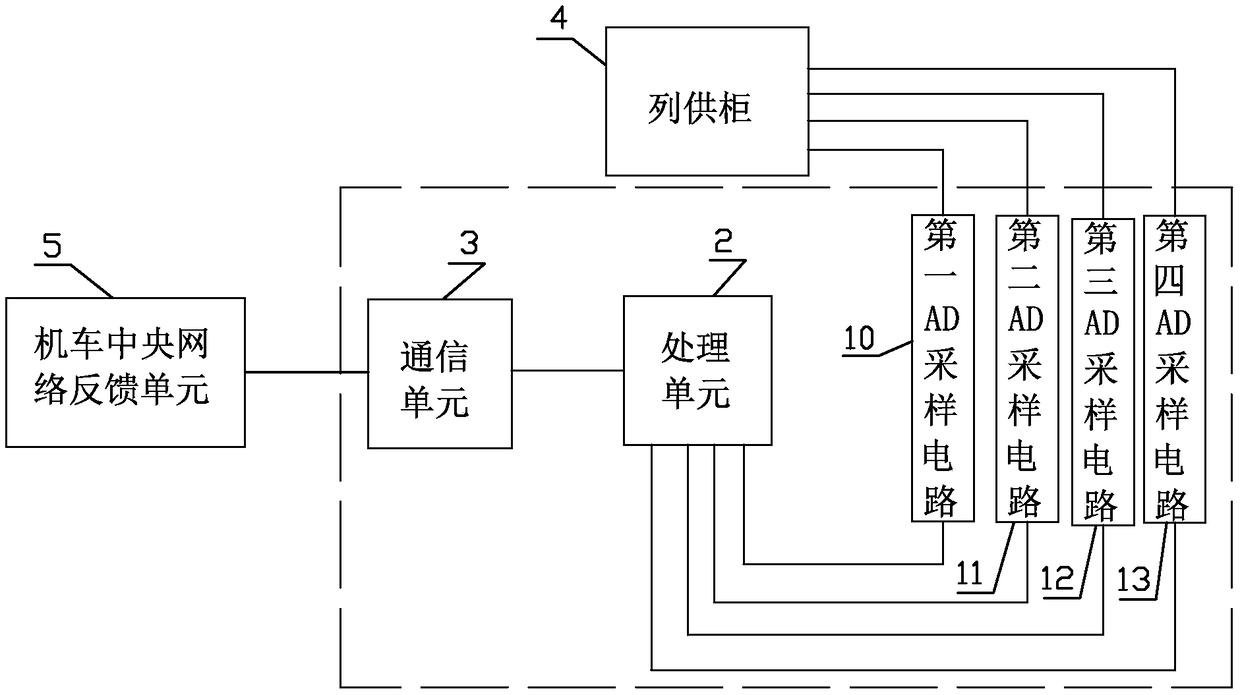

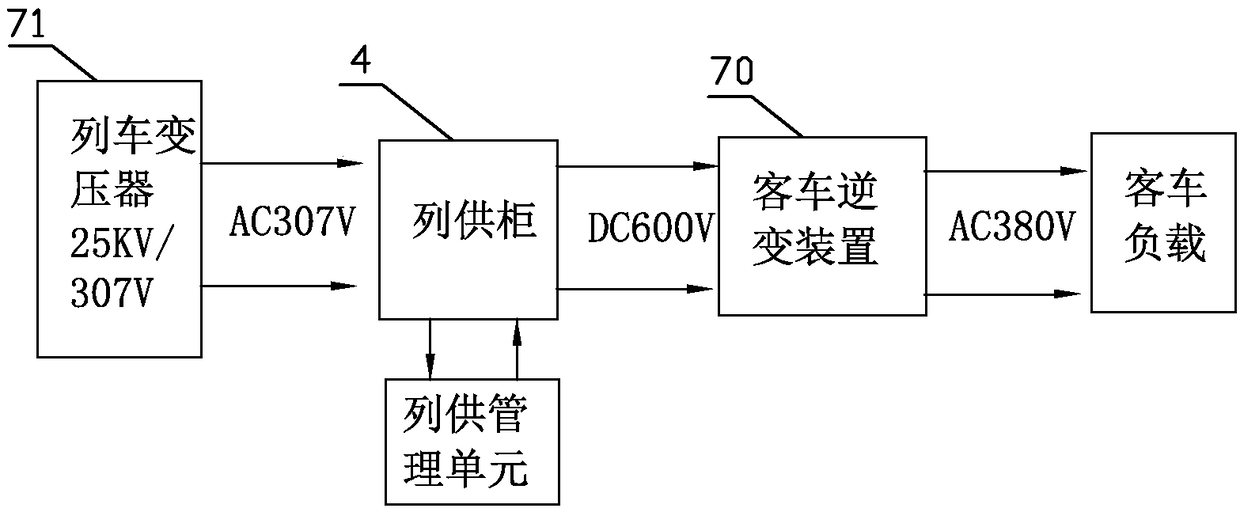

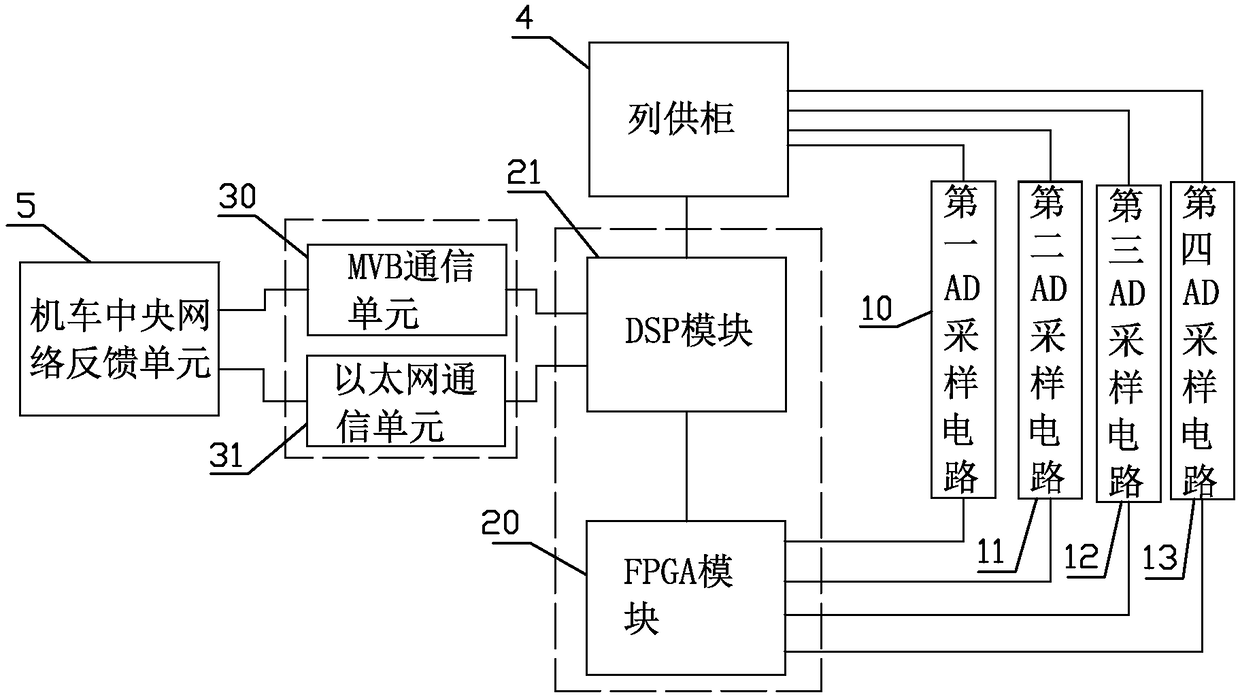

[0021] Such as figure 1 and figure 2 Shown is the centralized column supply management unit based on four-quadrant control disclosed in the present invention, including an AD data sampling unit, a processing unit 2, and a communication unit 3; the AD data sampling unit includes a first AD sampling circuit 10, a second AD Sampling circuit 11, the 3rd AD sampling circuit 12 and the 4th AD sampling circuit 13; Described first AD sampling circuit 10 is connected with the current sensor of column supply cabinet 4 input ends, and described second AD sampling circuit 11 is with column supply cabinet 4 The voltage sensor of input terminal is connected, and described the 3rd AD sampling circuit 12 is connected with the current sensor of column supply cabinet 4 output terminals, and described 4th AD sampling circuit 13 is connected with the voltage sensor of column supply cabinet 4 output terminals; The first, the second 2. The output terminals of the third and fourth AD sampling circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com