A laser energy control device and method

A technology of laser energy and control device, applied in the field of lithography, can solve problems such as short circuit of circuit board, laser beam cannot reach users, economic loss, etc., and achieve the effect of improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

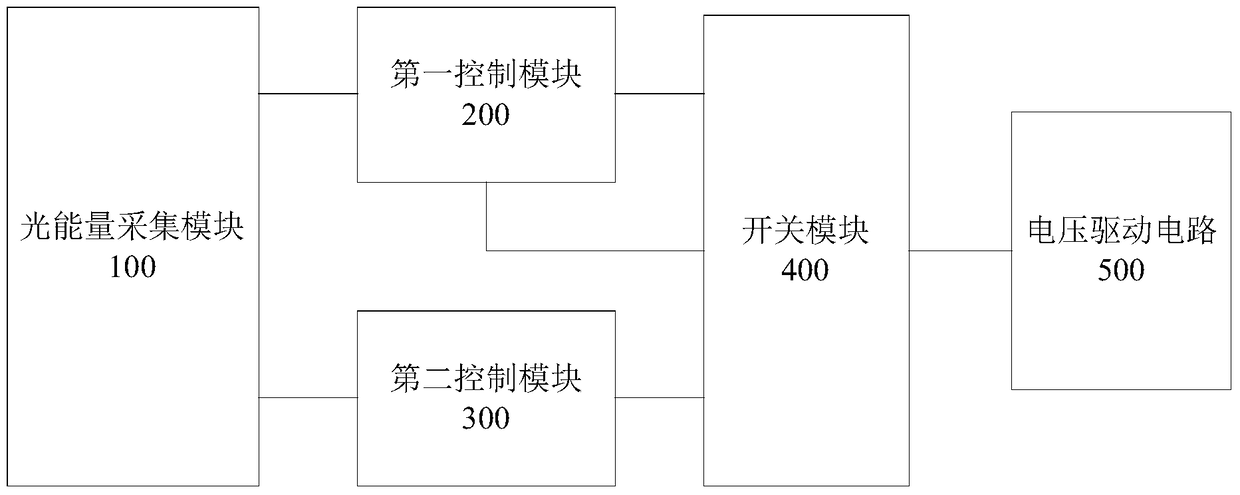

[0040] An embodiment of the present invention provides a laser energy control device, which is applied to a laser imaging system, and the device includes a light energy collection module 100, a first control module 200 and a second control module 300, such as figure 1 shown. The optical energy collection module 100 is coupled to the first control module 200 and the second control module 300 respectively, and both the first control module 200 and the second control module 300 are connected to the voltage driving circuit 500 output coupling.

[0041] Wherein, the optical energy collection module 100 is used to collect the optical energy signal of the laser beam output by the laser, and send the optical energy signal to the first control module 200 and the second control module 300 . The first control module 200 is used to compare the received light energy signal with the preset output voltage of the voltage drive circuit 500 to obtain a first difference, and feed back the first...

no. 2 example

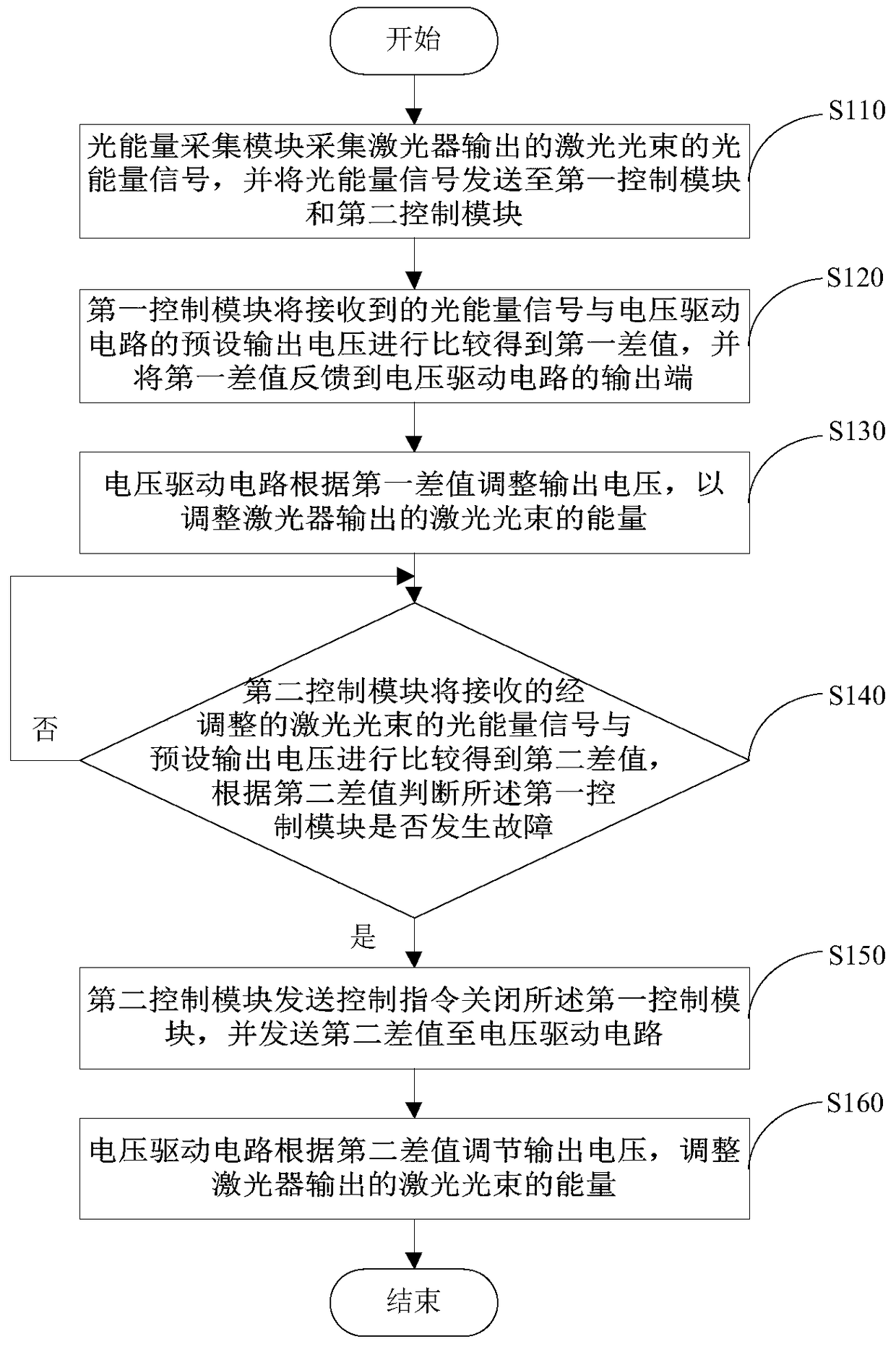

[0053] Such as figure 2 As shown, the embodiment of the present invention provides a laser energy control method, which is applied to a laser imaging system provided with a laser energy control device, and the laser energy control device includes an optical energy collection module, a first control module and a second control module ; the method comprising:

[0054] S110: The optical energy collection module collects an optical energy signal of the laser beam output by the laser, and sends the optical energy signal to the first control module and the second control module;

[0055]S120: The first control module compares the received light energy signal with the preset output voltage of the voltage drive circuit to obtain a first difference, and feeds back the first difference to the voltage drive the output of the circuit;

[0056] S130: The voltage driving circuit adjusts the output voltage according to the first difference, so as to adjust the energy of the laser beam out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com