Production device for antiallergic ventilating medical adhesive tape and production process thereof

A production equipment and anti-allergic technology, applied in medical science, bandages, non-adhesive dressings, etc., can solve problems such as affecting the aesthetics of the adhesive surface and the performance of the adhesive tape, and achieve the effect of beautiful adhesive surface, reducing allergens, and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

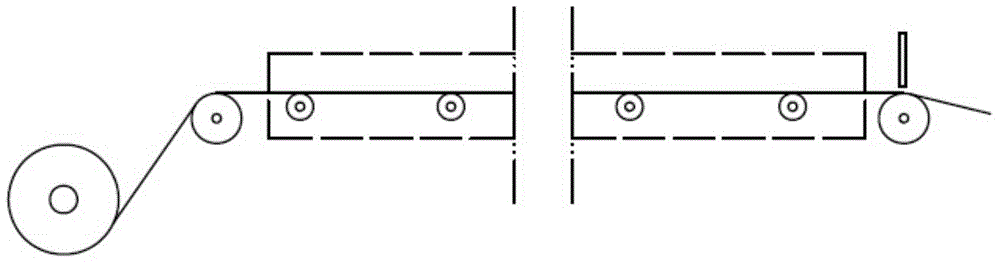

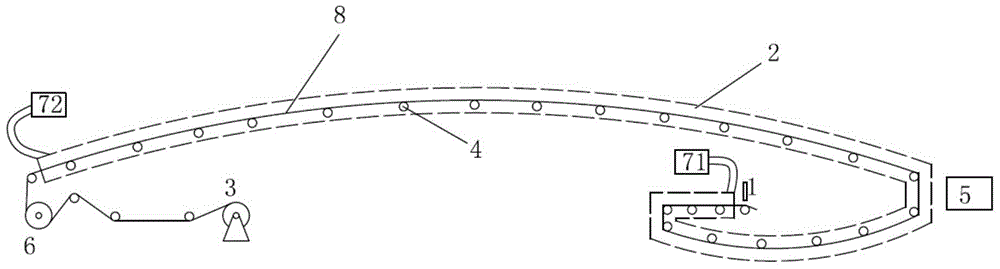

[0024] See figure 2 , the production equipment of the anti-allergic breathable medical adhesive cloth of the present embodiment comprises a gluing station 1, a transmission device, an oven 2, a winding device 3, an air blowing device 5, a cooling roller 6 and a heat exchange unit; the transmission device includes multiple A transmission roller 4 and a driving mechanism that provides power for the transmission roller 4; the transmission device is installed through the oven 2; a plurality of transmission rollers 2 of the transmission device are set from the gluing station 1 and continue to the winding device 4, forming sequentially Linear transmission section, rotary transmission section, ascending transmission section, circular arc transmission section and winding transmission section; the angle between the rotary transmission section and the ascending transmission section is ≥90°; the angle between the ascending transmission section and the arc transmission section is ≥90° ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com