Cosmetic composition containing fragments of bacterial cellulose film and method for manufacturing thereof

A cosmetic composition and bio-cellulose technology, applied in cosmetic preparations, medical preparations containing active ingredients, cosmetics, etc., can solve problems such as entanglement of bio-cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] [Example 1] Production of biocellulose film

[0032] First, prepare a liquid medium for pre-culture with glucose 10-30g / L and yeast extract powder 5-10g / L. After sterilizing, insert acetic acid bacteria (Glyconacetobacter xylinus) into aeration culture at 30°C for 3-7 days. It is used as an inoculum after a day. In addition, 10-30g / L glucose, 5-10g / L yeast extract powder, 2-10g / L Na 2 HPO 4 1-5g / L citric acid culture solution (sterilized at 121°C for 30 minutes), insert the previously cultivated inoculum, the inoculum amount is 5%-10%, and carry out static culture in a culture basin of A4 size. The culture temperature is 26-32°C. After culturing for 3 to 10 days, the biocellulose membrane is taken out, washed with 0.1% to 5% NaOH, sterilized, and then left to stand for one day. After washing with water for 3 to 4 times, and neutralizing with acid, the biological cellulose film was obtained for use in subsequent examples.

Embodiment 2

[0033] Production of Example 2 Biocellulose Film Fragments

[0034] Take 7.5kg of biocellulose film (moisture content about 98% by weight) and put it into a pulverizer (TBSP-330), add an equal amount of water 7.5kg, pulverize at a speed of 2,000rpm, and rest for 1 minute every 5 minutes of pulverization. When the pulverization time reaches more than 30 minutes, the biocellulose film fragments of pulverization are poured out, put into a sterilizing ax and sterilized for 30 minutes, add bacteriostat (0.15% by weight methyl Paraben (methyl Paraben) and 0.01% by weight of methyl isothiazolinone (methyl isothiazolinone)), made into the first solution, stored for subsequent use.

[0035] Then, before use, add 50g of the first solution to 200g of sterile water at a ratio of 1:4, add 0.2% Tween 80, put it into a homogenizer, and then homogeneously pulverize it for 30-60 minutes to form the second solution Second solution. The resulting second solution is the base for the subsequent ...

Embodiment 3

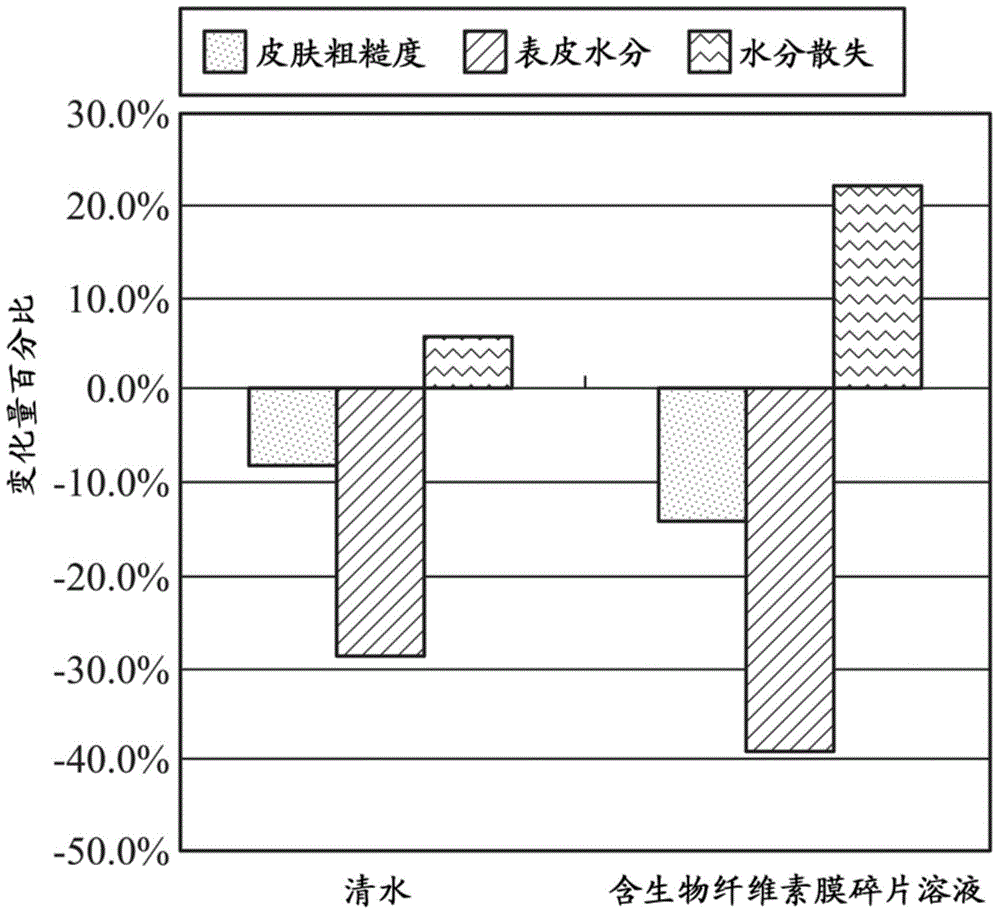

[0036] Exfoliating effect of embodiment 3 biocellulose film fragments

[0037] Take the second solution (biological cellulose membrane fragment solution) of Example 2, rub it on human skin for 30 seconds, and compare the efficacy before and after use. Using CK Electronic multifunctional skin detector, Visioscan VC 98 is used to detect skin surface roughness, MPA 580 Cutometer is used to detect skin surface moisture content, and Tewameter TM 300 is used to detect skin surface moisture loss rate. The result is as figure 1 shown. Compared with simply using clean water to clean the face, those who use the solution containing biocellulose membrane fragments can reduce skin roughness, increase skin moisture loss and reduce skin moisture content, showing that biocellulose membrane fragments solution has a good effect on skin removal. Horny function.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap