Multifunctional stone crusher

A stone crusher, multi-functional technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., to achieve the effect of improving centrifugal effect, improving crushing efficiency, and reducing the number of bristles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

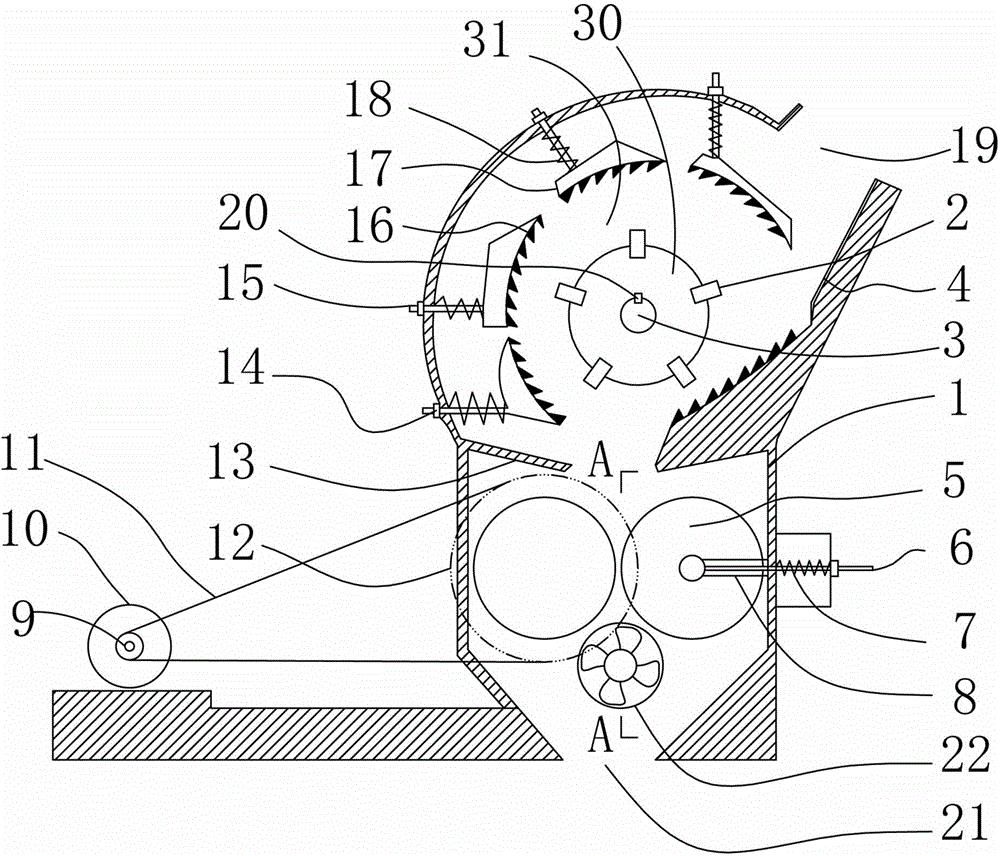

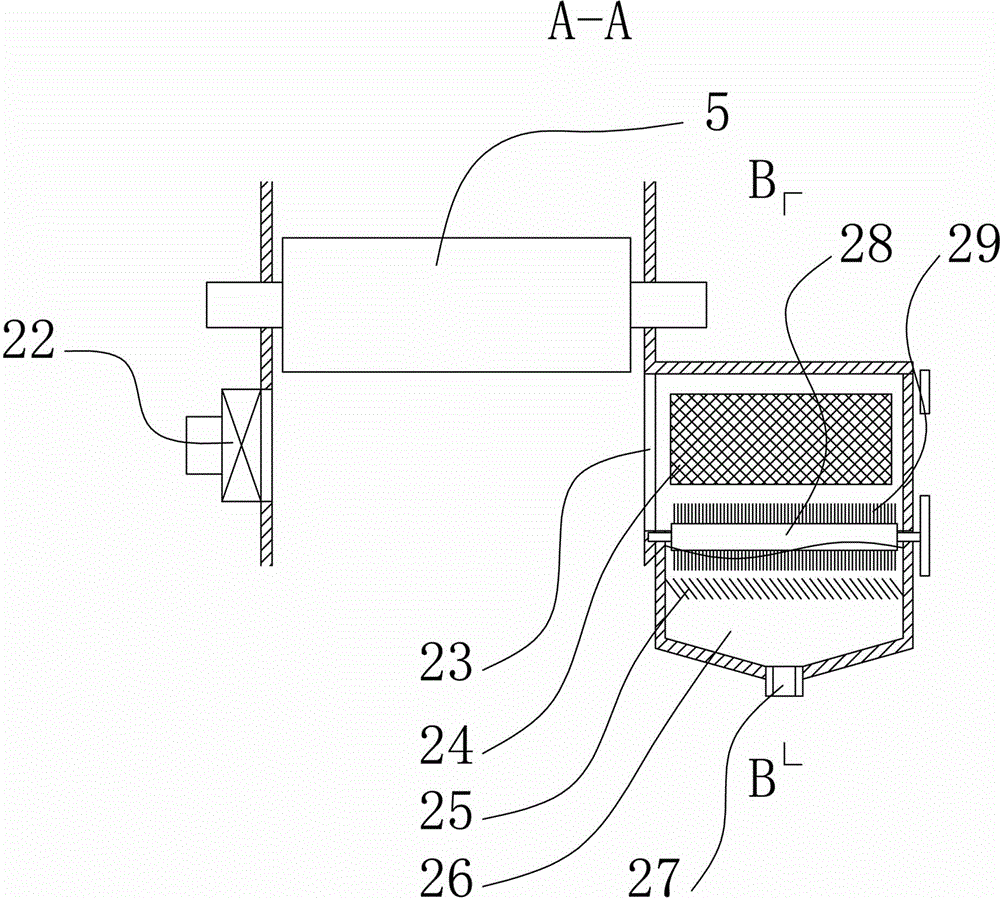

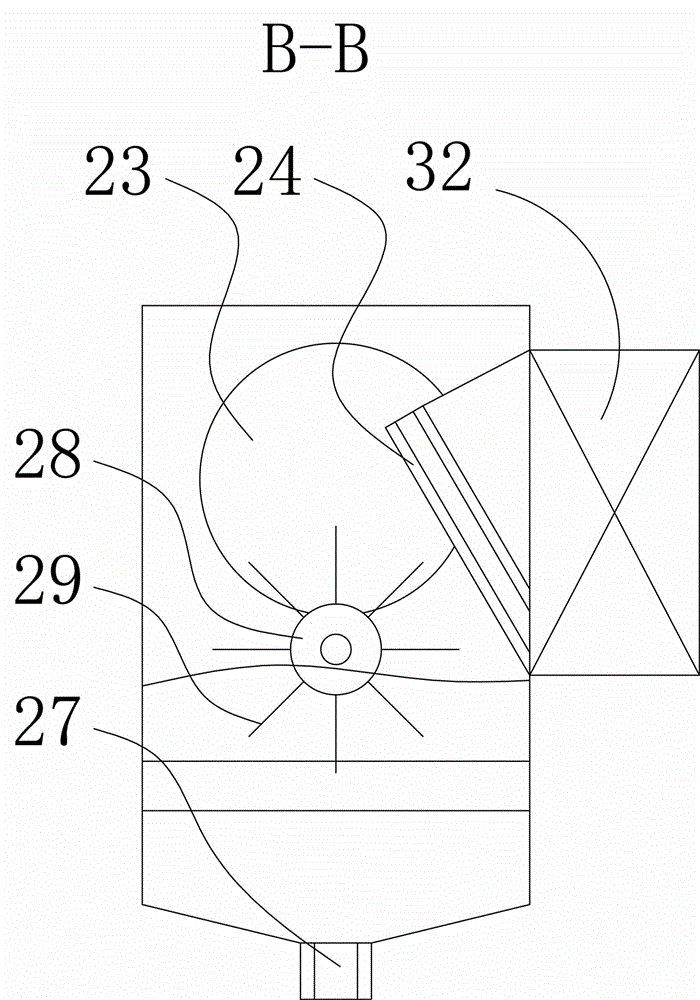

[0023] Such as Figure 1~4 Among them, a multi-functional stone crusher includes a crushing chamber and a crushing chamber, wherein the crushing chamber is located below the crushing chamber, at least one pair of crushing drums 5 are arranged in the crushing chamber, and an air inlet is provided on the side below the crushing drum 5, A settling bin 26 is arranged on the opposite side of the air inlet, and the corresponding position of the settling bin 26 and the air inlet is provided with a dust inlet 23, and a rotating dust filter roller 28 is arranged in the settling bin 26. There is a filter screen 24 covering the air outlet. After the ore or stone is crushed in the crushing chamber, it falls into the crushing chamber. After being crushed by the crushing drum 5 in the crushing chamber, the wind from the air inlet blows the stone powder into the dust inlet 23, and is filtered by the high-speed rotating dust in the sedimentation bin 26. The droplets thrown off by the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com