Anti-skid structure of tractor tire and tractor tire

A tractor, anti-skid technology, applied in the direction of tire tread/tread pattern, agricultural vehicle tires, off-road vehicle tires, etc. Extended length, reduced stress concentration, increased grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

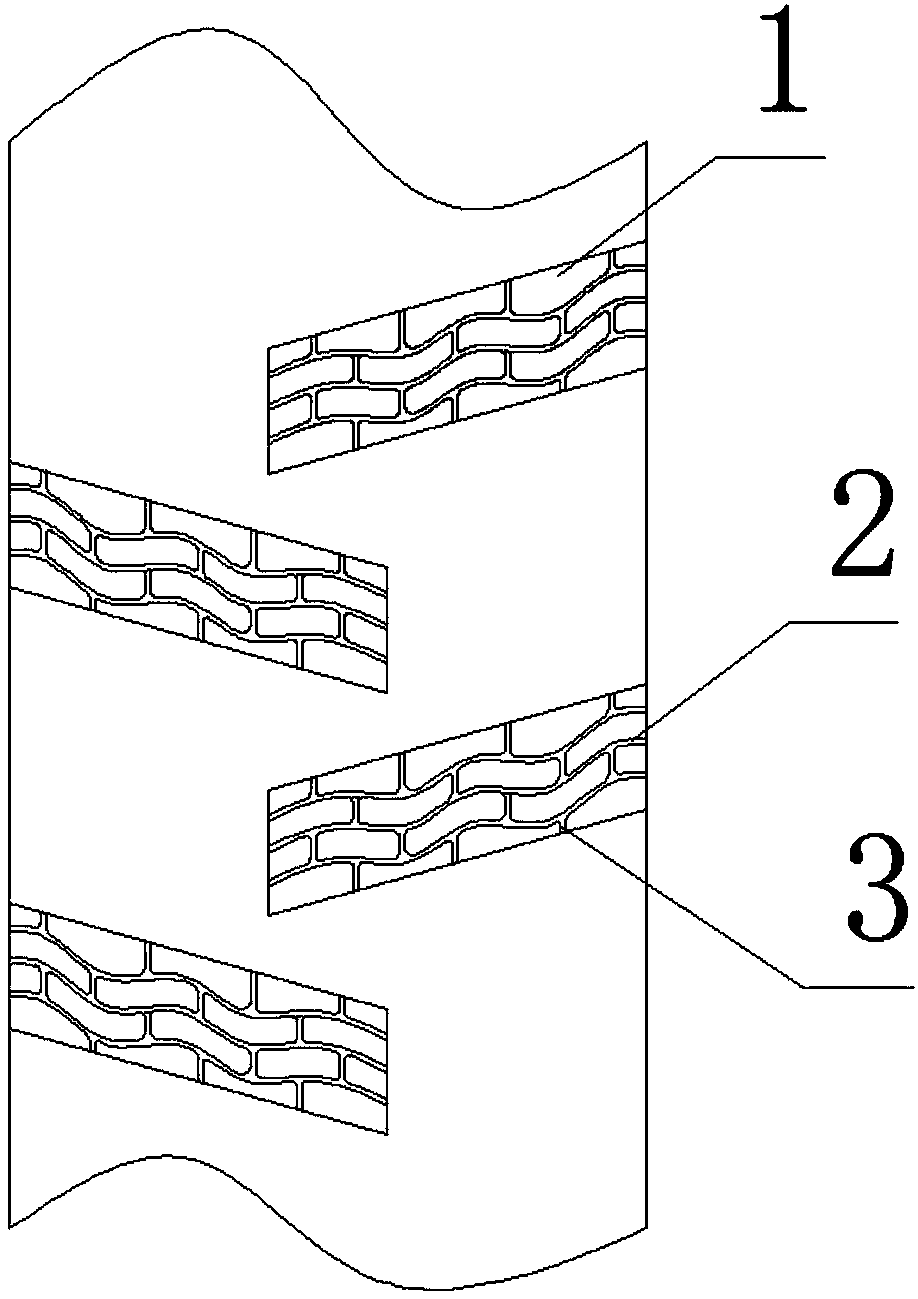

[0020] Such as figure 1 As shown, an anti-skid structure of a tractor tire includes staggered and evenly distributed protrusions 1 along the width direction of the tire; The top surface of the protrusion 1 is provided with an anti-slip structure.

[0021] Non-slip construction includes

[0022] The first groove 2 is at least one first groove 2 opened along the length direction of the protrusion 1; the cross section of the first groove 2 is semicircular;

[0023] The second groove 3, two adjacent first grooves 2 are connected through a plurality of second grooves 3; the outermost second groove 3 extends to the edge of the protrusion 1; the cross section of the second groove 3 is semicircular.

[0024] The first groove 2 is curved, which may be S-shaped, or curved in the middle towards the forward direction of the vehicle, forming an Ω-shaped overall.

[0025] The junction of the second groove 3 and the first groove 2 is rounded to avoid stress concentration.

[0026] Three...

Embodiment 2

[0029] A tractor tire, comprising a tire and the anti-skid structure arranged on the surface of the tire as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com