Surface cleaning device for solar cell module

A surface cleaning device, a technology for solar cells, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of power consumption, large movement resistance, poor cleaning effect, etc. Snow or foreign matter, low running cost, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

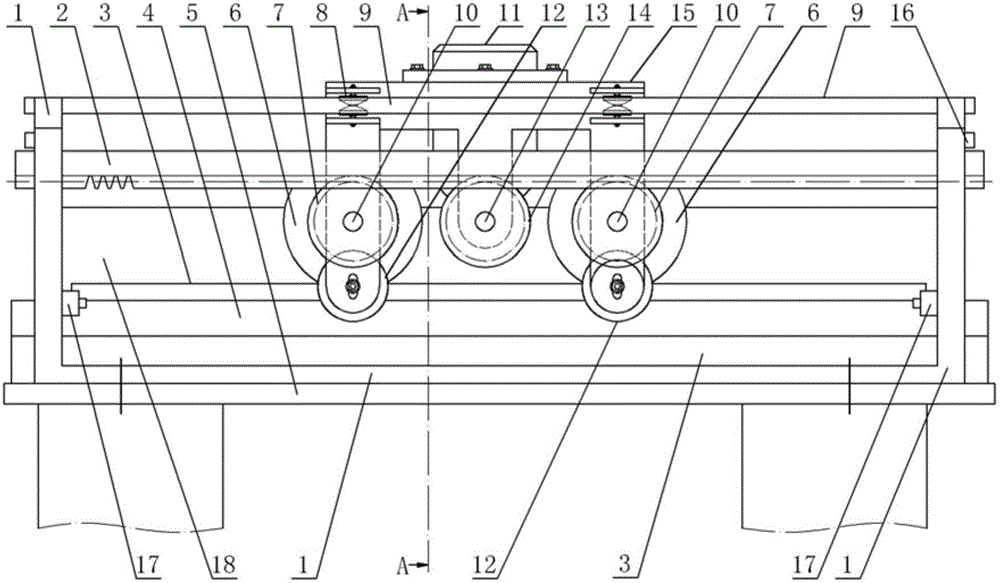

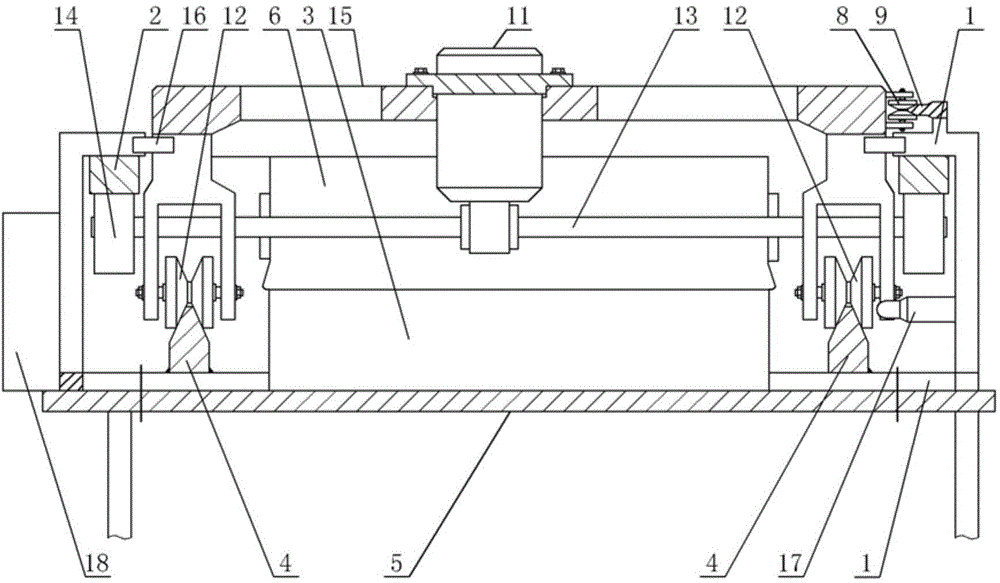

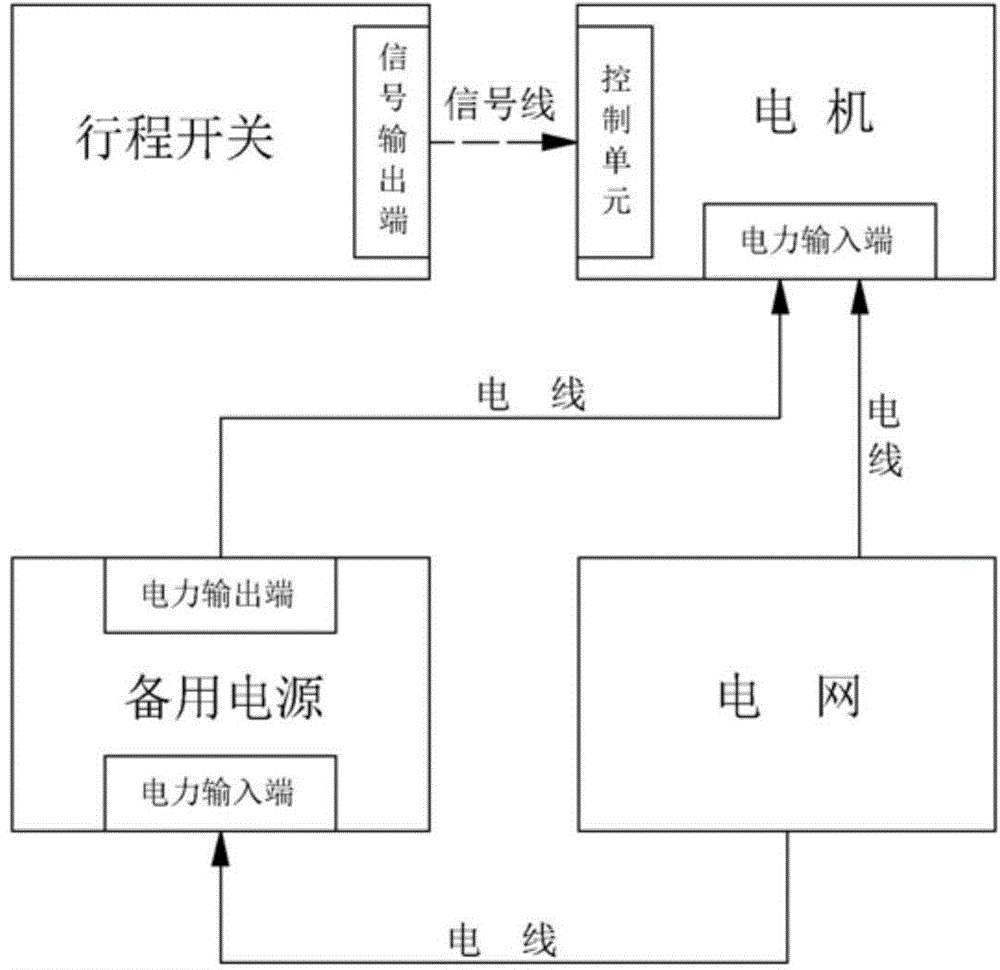

[0012] The solar cell module surface cleaning device has a frame 1, a support rail 9, a rack 2, a gantry track 4, a gantry frame 15, a motor 11 and several roller brushes 6, and the frame is fixed on the solar cell module 3 by a bolt assembly On the mounting frame 5 of the gantry frame, wherein the support rail, the rack and the gantry track are fixedly connected with the frame respectively, and the support rail, the rack and the gantry track are arranged in parallel, and the feet of the gantry frame are movably connected with the gantry track through the walking wheels 12, so that The two feet of the gantry frame are located on both sides of the solar cell module. The side of the gantry frame is equipped with support wheels 8, which are flexibly connected to the support rails. The support wheels and walking wheels are pulleys. The rails of the gantry track The surface is a trapezoidal surface that matches the pulley. The trapezoidal surface can reduce the accumulation of snow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com