Thin-wall pipe chipless cutting device and thin-wall pipe chipless cutter

A cutting device and thin-walled pipe technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of non-circumferential shrinkage of the pipe mouth, adduction of the incision, high manufacturing cost, etc., and achieve no deformation and burr in the incision, The overall structure is simple and the cut is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

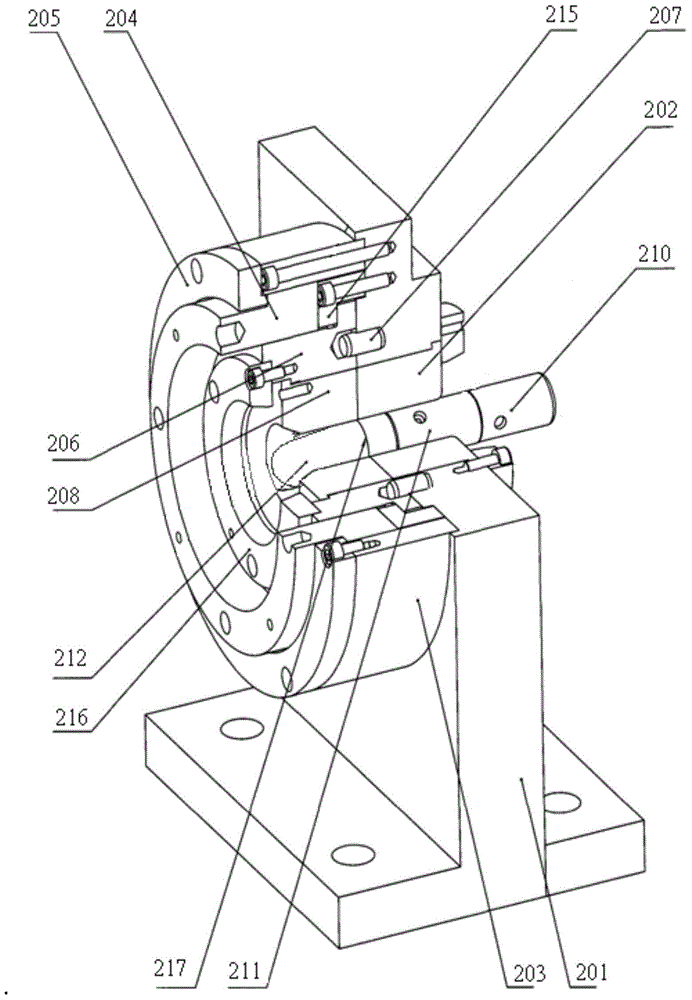

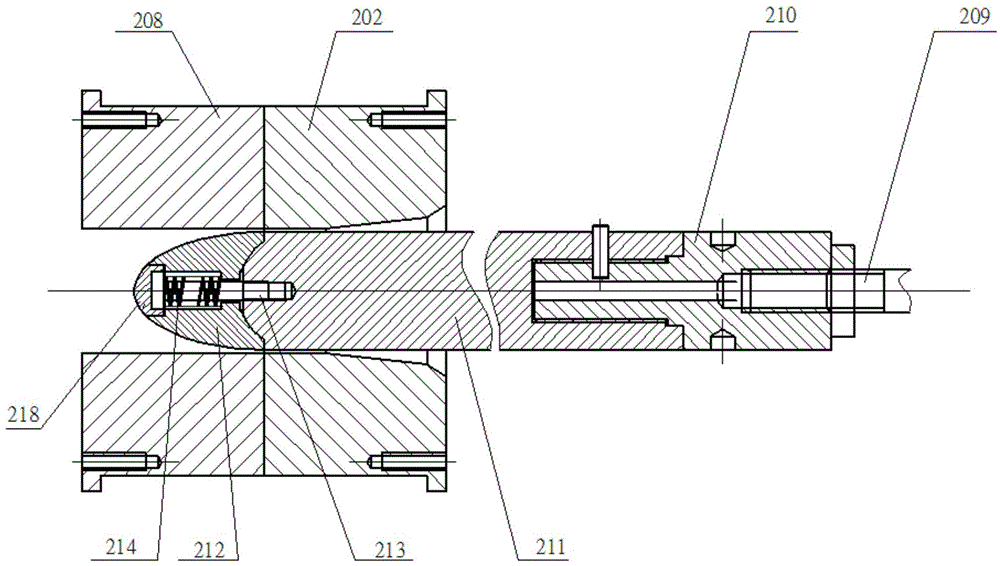

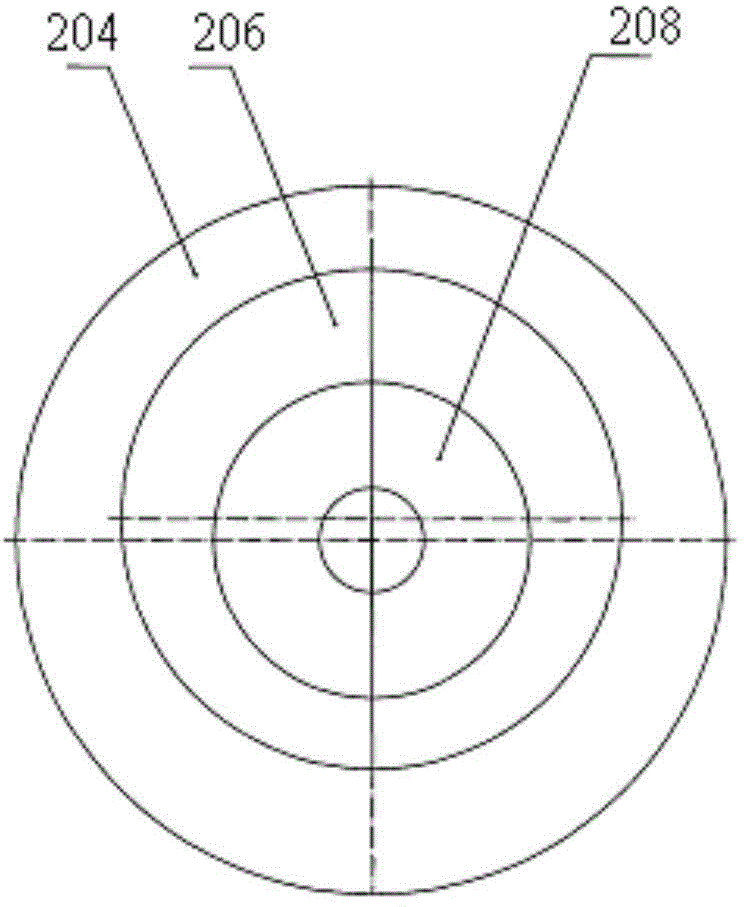

[0022] Such as figure 1 , 2 As shown, the chip-free cutting device for thin-walled pipes includes: a fixed seat 201, a fixed cutting die 202 is arranged in the fixed seat 201, a rotary jacket 203 is arranged on one side of the fixed seat 201, and the rotary jacket 203 moves through the first pressure ring 205. A rotary sleeve 204 with internal and external eccentricity is provided, and the first pressing ring 205 is fixed on the rotary outer sleeve 203 through fixing bolts. In the rotary sleeve 204, an outer mold base 206 with internal and external eccentricity is installed through the second pressing ring 215. The second pressing ring 215 Fixed on the fixed seat 201 by fixing bolts, the eccentricity of the rotary sleeve 204 and the outer mold base 206 is equal, and its value must be greater than the sum of the pipe wall thickness and the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com