Oil pump spur gear shaft machining clamp

A wheel shaft and fixture technology, applied in the direction of manufacturing tools, components with teeth, metal processing equipment, etc., can solve the problems of not being able to process the teeth of the gear part, reduce the yield of finished products, increase the production cost, etc., and achieve easy disassembly, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, a machining jig for an oil pump spur gear shaft as an example of the present invention will be described based on the drawings.

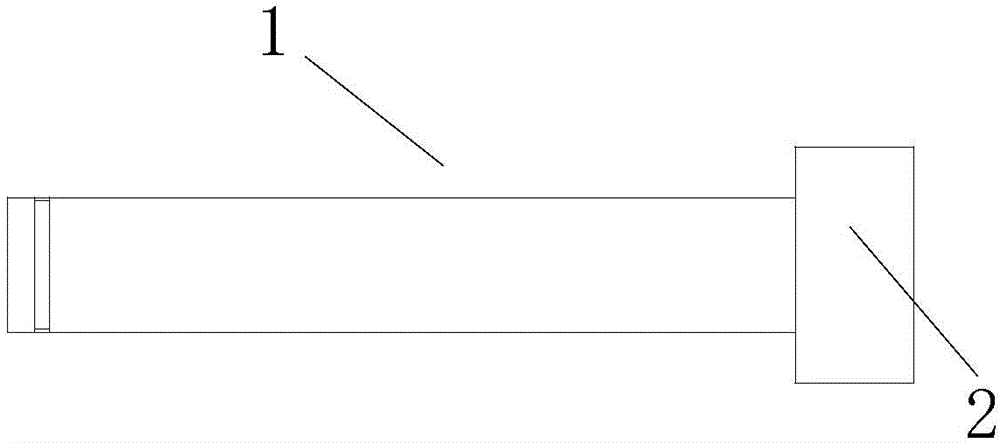

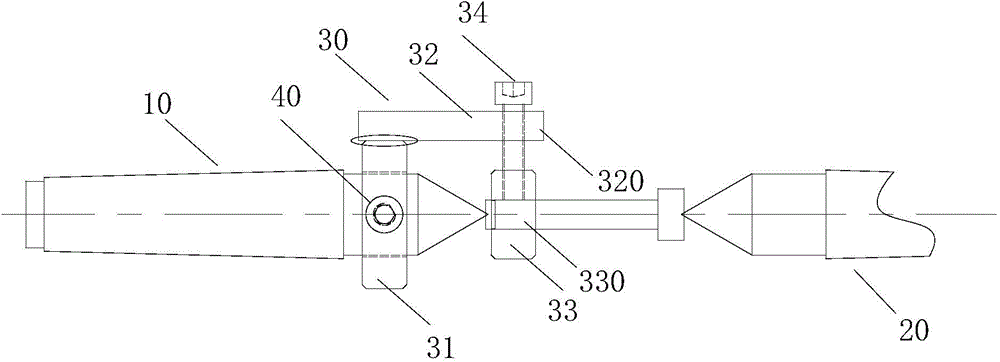

[0016] figure 1 It is a schematic side view showing the spur gear shaft of the oil pump of the present invention. figure 2 It is a schematic front view showing a machining jig for an oil pump spur gear shaft according to the present invention.

[0017] Such as figure 1 As shown, the spur gear shaft of the oil pump of the sewing machine includes a shaft part 1 and a gear part 2 . When processing such a gear shaft, the blank of the spur gear shaft of the oil pump is usually clamped between two ejector pins, and then the teeth of the gear part are rolled out while the ejector pin is rotated by a hobbing tool.

[0018] Such as figure 2 As shown, the processing fixture of the spur gear shaft of the oil pump of the present invention has a left push rod 10 and a right push rod 20 whose axes are on the same straight line, and a fixing mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com