Boring clamp for oil pump end cover

A technology for end caps and oil pumps, which is applied in the field of boring jigs, can solve the problems of not easy oil pump end caps, processing through holes, and no fast and convenient clamping of oil pump end caps, so as to improve machining accuracy and high production efficiency , the effect of fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, a boring jig for an oil pump cover as an example of the present invention will be described based on the drawings.

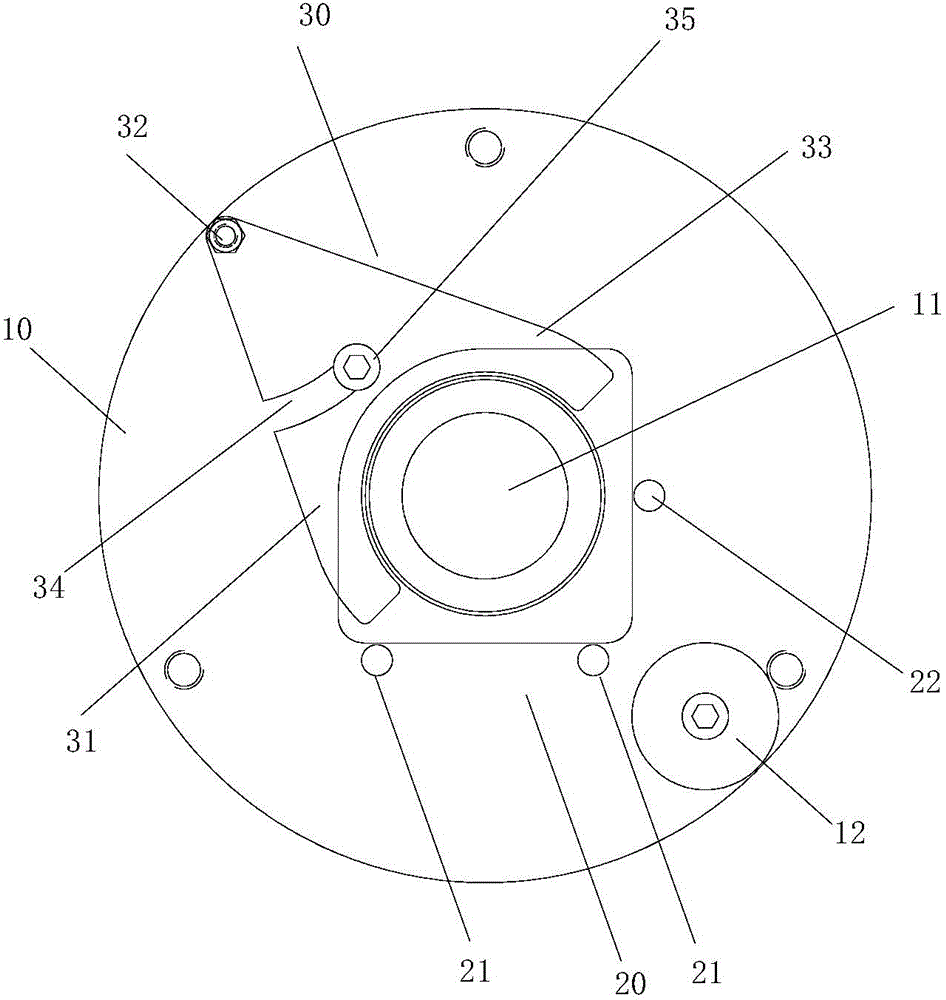

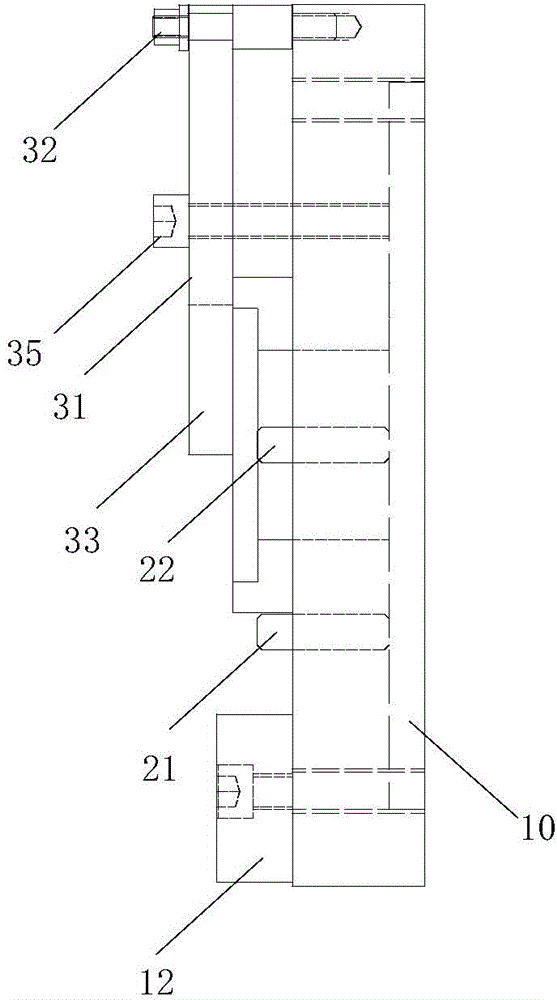

[0017] figure 1 It is a schematic front view showing the oil pump end cover of the present invention. figure 2 It is a schematic front view showing the boring jig of the oil pump end cover of the present invention. image 3 It is a schematic side view showing the boring jig of the oil pump end cover of the present invention.

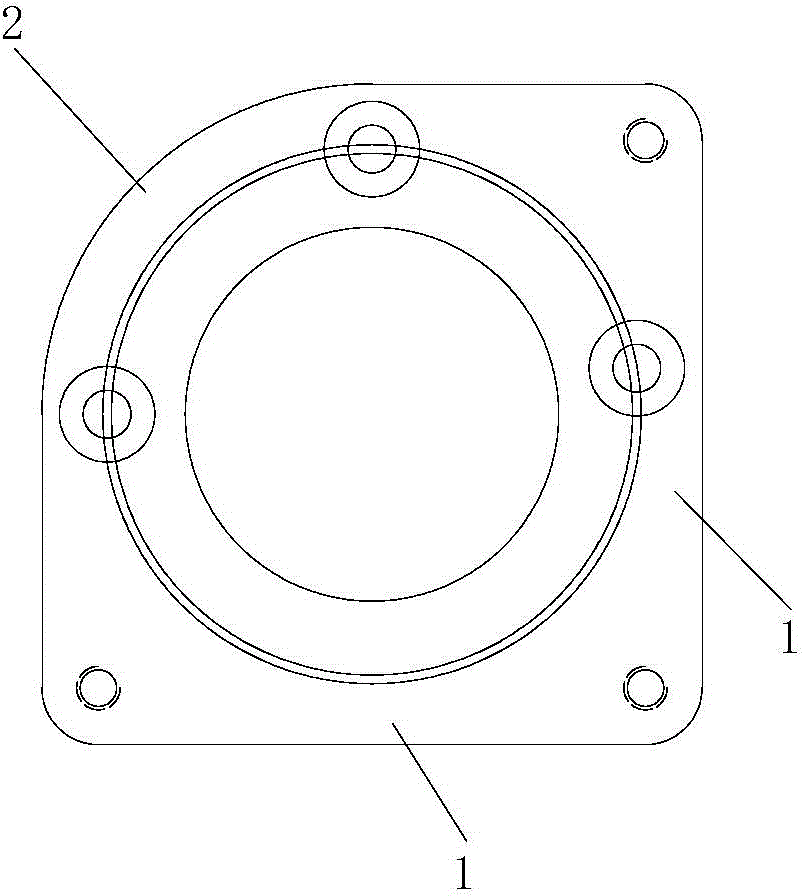

[0018] Such as figure 1 As shown, the oil pump end cover is formed in a plate shape, with two mutually perpendicular flat sides 1 and an arc side 2 connecting the two flat sides.

[0019] Such as figure 2 , image 3 As shown, the boring jig for the oil pump end cover has a clamping chassis 10 , a positioning member 20 and a clamping member 30 .

[0020] The clamping chassis 10 is connected with the main shaft of the boring machine, and a through hole 11 through which the boring tool can pass is formed in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com