Online two-way stretching device of plastic pipes

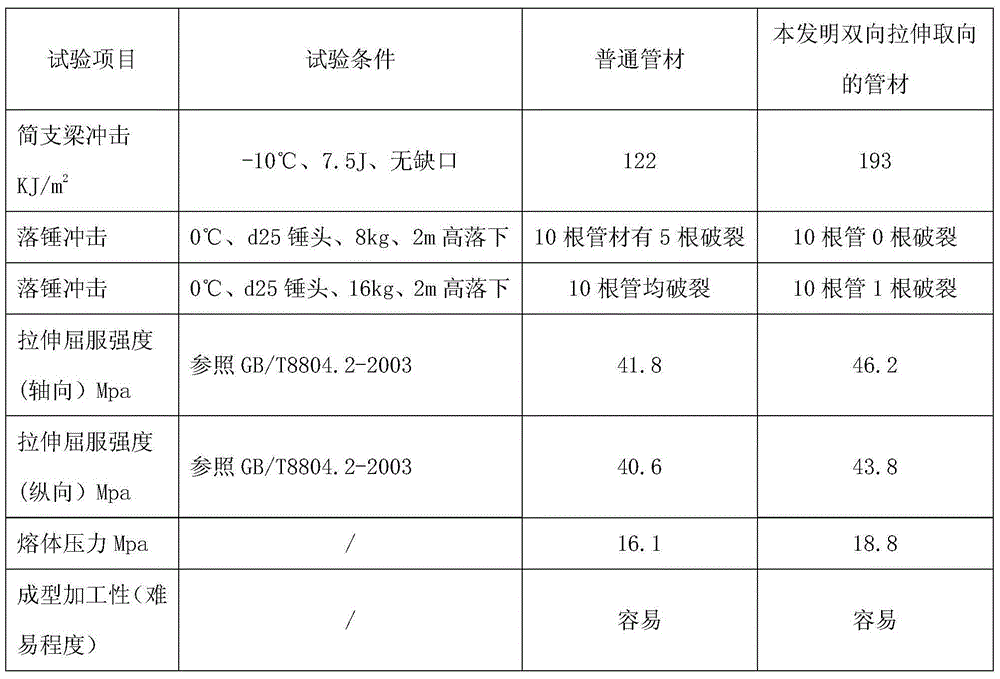

A biaxial stretching and plastic pipe technology, applied in the field of plastic processing equipment, can solve the problems of expensive equipment, complicated equipment and process, etc., and achieve the effect of simple structure, improved efficiency and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

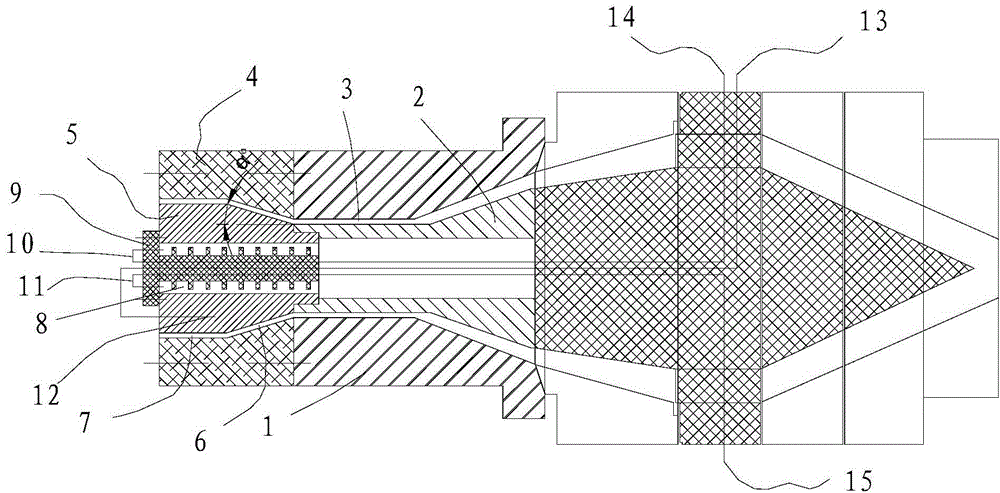

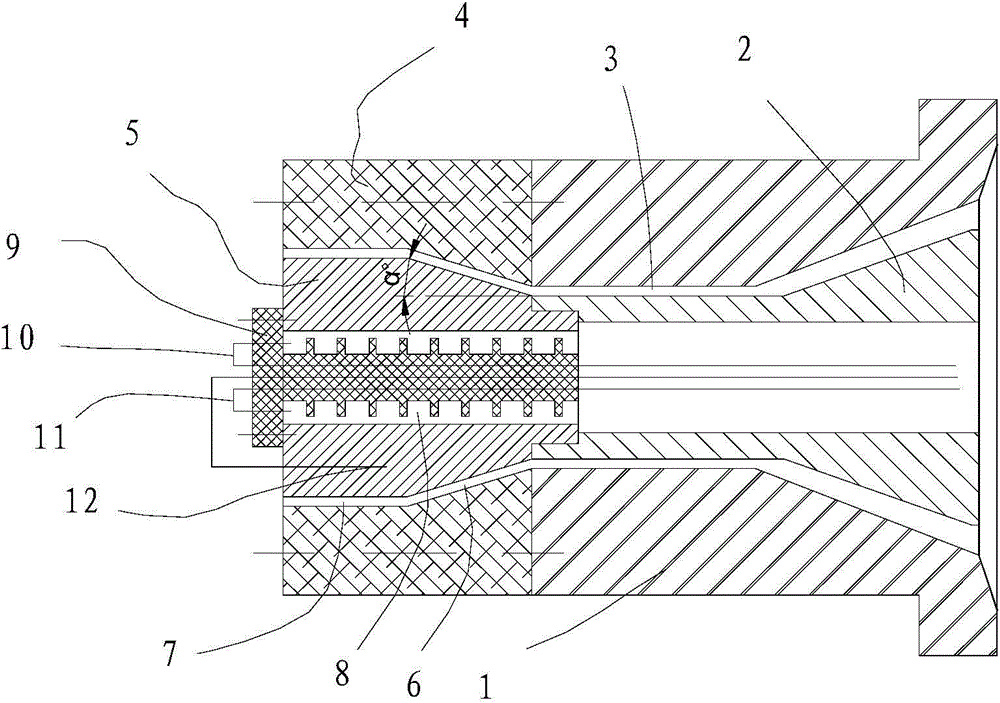

[0018] refer to Figure 1-2 , an online bidirectional stretching device for plastic pipes, including a die 1, a mandrel 2 and an annular flow channel 3 between the die 1 and the mandrel 2 arranged on the extrusion die, and it is also provided with the die The connected cavity 4 and the core 5 connected with the mandrel 2, wherein between the cavity 4 and the core 5 are sequentially provided with an expanding annular flow channel 6 communicating with the annular flow channel 3 and an expanding annular flow channel 6 connected horizontal annular flow channel 7, a cavity 8 is provided in the core 5, and a cyclone 9 is provided in the cavity 8, and the inlet pipe 10 and the outlet pipe 11 of the cyclone 9 are respectively connected to an external mold temperature controller The medium outlet 14 and the medium inlet 15. A thermocouple 12 connected to a thermocouple interface 13 of an external mold temperature controller is arranged inside the core 5 . The included angle α between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com