Safe accidental-opening-prevention container cover

A technology for preventing mis-opening and container caps, which is applied in the field of closures, and can solve problems such as mispressing containers, spilling liquids, and causing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

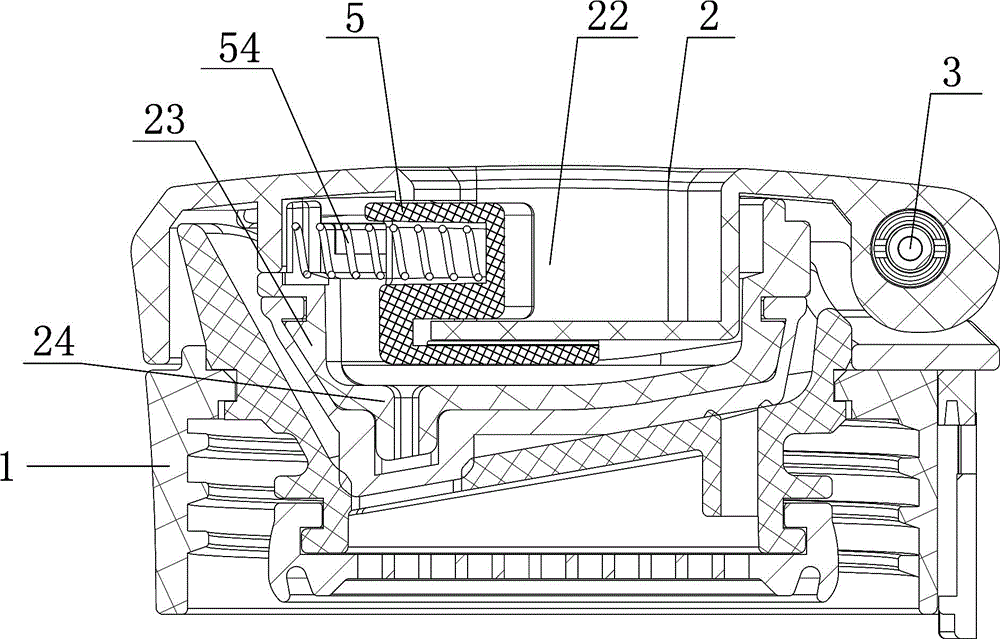

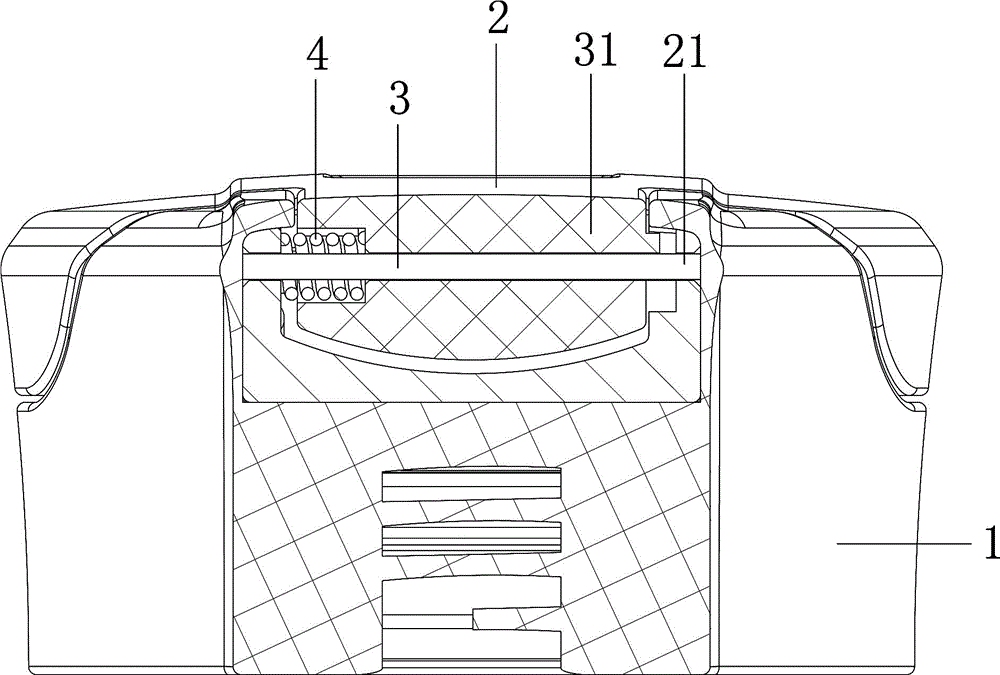

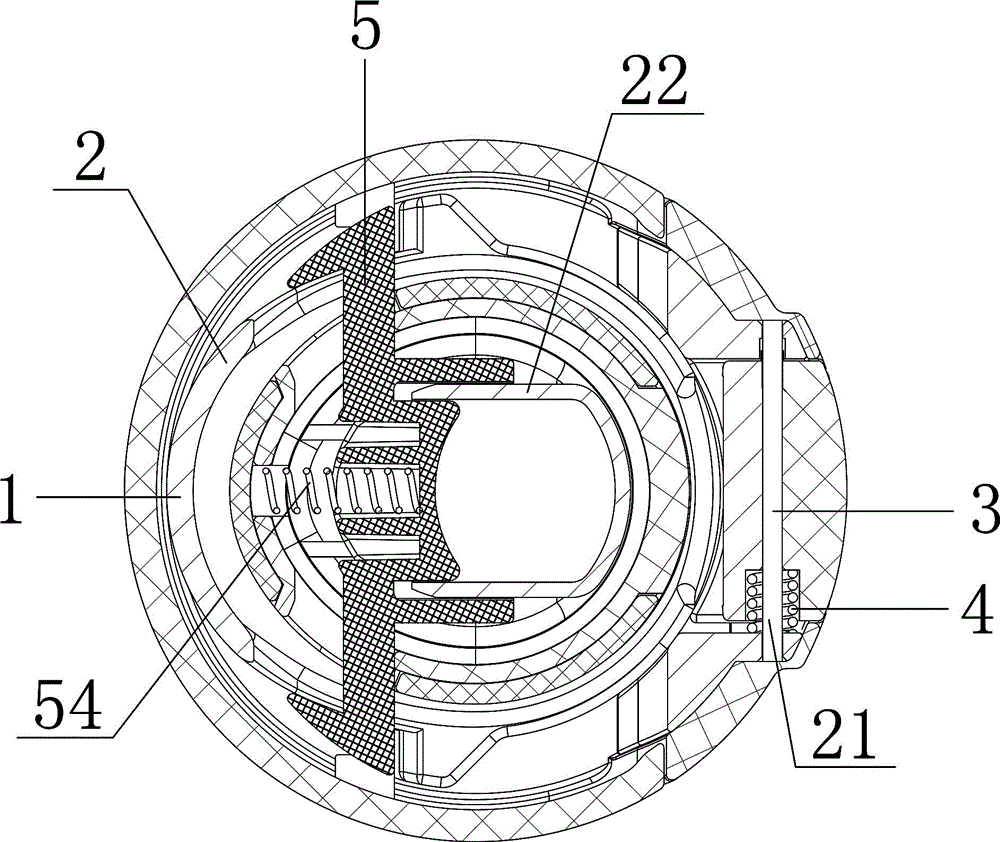

[0051] A safe anti-mis-opening container cover, including a base 1, a flip cover 2, a rotating shaft 3, a torsion spring 4, a flip cover lock 5 and a plug core 6, such as Figure 1 to Figure 8 As shown, the specific structure is:

[0052] Internal threads are tapped on the inner side of the base 1; external threads are tapped on the outer side of the top of the container 10, and the openings of the base 1 and the container 10 are connected by threads;

[0053] One side of the flip cover 2 is provided with a shaft hole 21, the shaft 3 is sleeved in the shaft hole 21, the torsion spring 4 is sleeved outside the shaft 3, the two ends of the shaft 3 are respectively sleeved on the two ends of the base 1 side, the torsion spring 4 The two ends are against the base 1 and the flip cover 2 respectively;

[0054] A locking chute 22 is provided at the center of the inner end surface of the flip cover 2, and one end of the locking chute 22 is open;

[0055] Flip lock 5 such as Figure...

Embodiment 2

[0062] A safe anti-mis-opening container cover, including a base 1, a flip 2, a rotating shaft 3, a torsion spring 4, a flip lock 5 and a plug core 6, and also includes a sealing gasket 25 and a filter gasket 62, such as Figure 11 ~ Figure 13 As shown, the specific structure is:

[0063] Gasket 25 as Figure 12 As shown, the chute cover 23 is covered with a sealing gasket 25, and the sealing gasket 25 is attached to the outer surface of the chute cover 23 and the cover tongue 24. When the lock catch 52 hooks the lock hook 61, the flip cover 2 is fixed on the base 1 When it is on, the sealing gasket 25 attached to the outside of the cover tongue 24 is embedded in the water outlet hole of the plug core 6;

[0064] filter liner 62 as Figure 13 As shown, the bottom of the plug core 6 is covered with a filter pad 62, and the filter pad 62 has filter holes.

[0065] In this embodiment, both the sealing gasket 25 and the filter gasket 62 are made of silica gel.

[0066] Other s...

Embodiment 3

[0069] A safe anti-mis-opening container cover, including a base 1, a flip cover 2, a rotating shaft 3, a torsion spring 4, a flip cover lock 5, a plug core 6, a sealing gasket 25 and a filter gasket 62, and a rotating shaft seat 11, a damper 31 and damping paste such as Figure 14 and Figure 15 As shown, the specific structure is:

[0070] A shaft hole is opened at both ends of the shaft seat 11, and a mortise is opened outside a shaft hole of the shaft seat 11, and the shaft seat 11 is embedded in one side of the base 1;

[0071] The damper 31 and the torsion spring 4 are respectively sleeved on the two ends of the rotating shaft 3, and the outer surface of the damper 31 is attached to the inner wall of the rotating shaft hole 21 of the flip cover 2, and a damping paste is applied between the damper 31 and the rotating shaft hole 21. The outer end surface of 31 is provided with a tenon, and the two ends of the rotating shaft 3 are inserted into the two shaft holes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com