A mine underground unloading device

A unloading device and mine technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of endangering the physical and mental health of miners, low safety factor, high labor intensity, etc., and achieve manpower saving, high operating efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

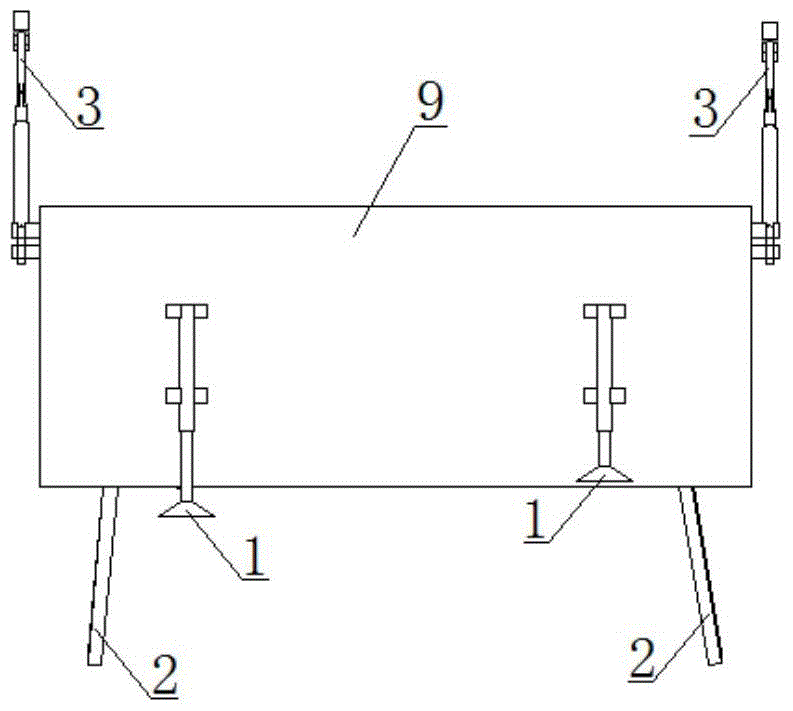

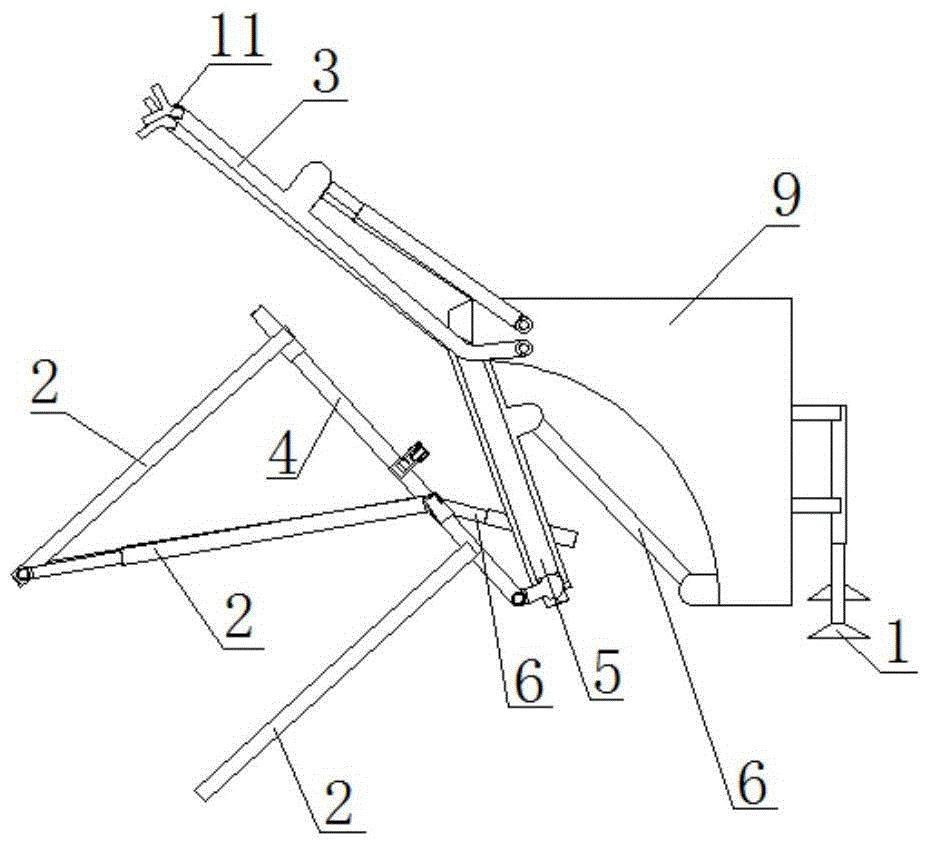

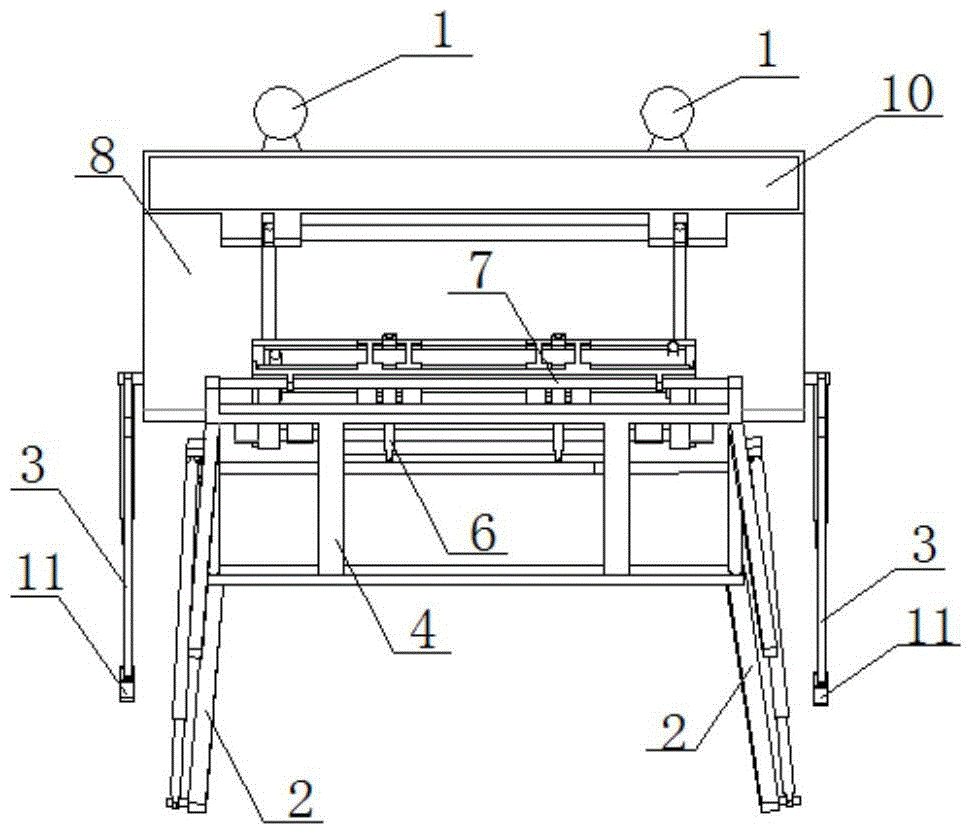

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 The implementation of the present invention is described, the unloading device is composed of a rear hydraulic cylinder 1, an arm 2, a support rod 3, an outer frame 4, an inner frame 7, a fuselage 9, a connecting rod 6, a front claw 11, a slide rail 5, and a hopper 8 , Leak port 10, the hydraulic pump station is used as the power source to drive each hydraulic pump to complete various tasks. The working process is as follows: when the mine car reaches the device, the rear hydraulic cylinder 1 is propped up and fixed on the ground to lift the device off the ground; the arm 2 is closed to the middle to fix the mine car; the support rod 3 falls to make it The front paws 11 are fixed on the track; the outer frame 4 moves up in the slide rail 5, lifts the mine car, and makes the mine car leave the track. Under the joint action of the power provided by the hydraulic connecting rod 6 and the turning of the inner frame 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com