Fixed-type aseismic noise reduction rubber support for rail transit bridge

A rail transit and rubber bearing technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of no large-scale horizontal displacement of the beam body, insignificant and serious shock absorption and isolation functions, etc., to ensure safety and stability. performance, ensure the safety and stability of the line, and reduce the deflection of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

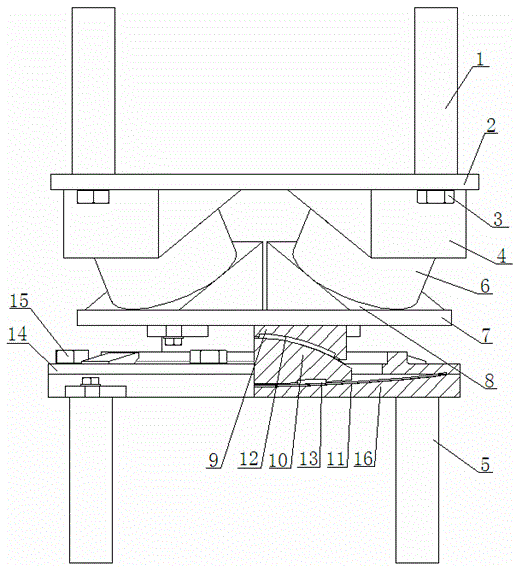

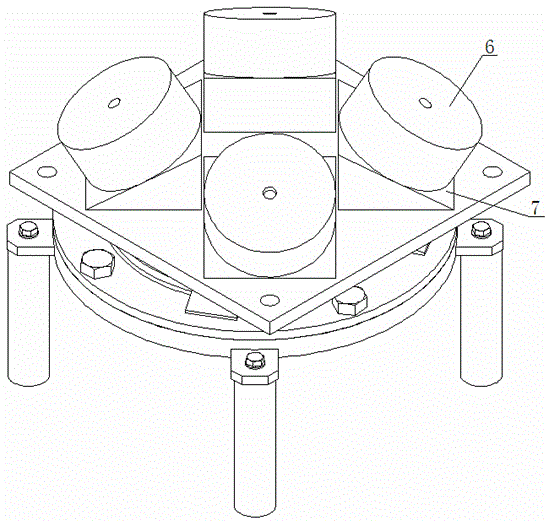

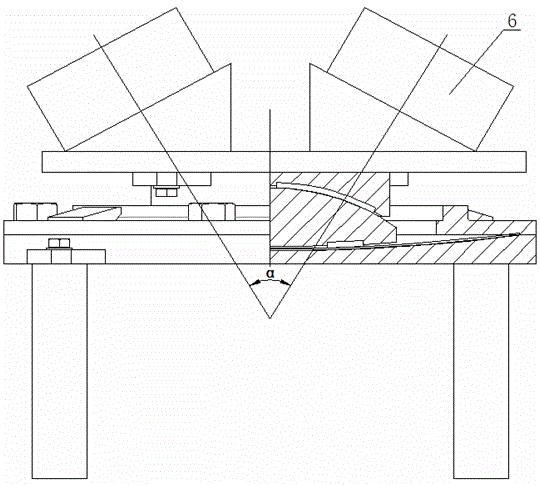

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 1 to Figure 3 , a fixed anti-seismic and noise-reducing rubber bearing for a rail transit bridge, comprising an upper bearing plate 2 and a middle seat plate 8, and four upper anchor rods 1 are arranged on the upper bearing plate 2 . The middle seat plate 8 is provided with four lower wedge-shaped fixing blocks 7, and the four lower wedge-shaped fixing blocks 7 are arranged oppositely; the bottom of the upper support plate 2 corresponds to the four lower wedge-shaped fixing blocks 7 respectively Four upper wedge-shaped fixing blocks 4 are provided. Vulcanized rubber plates 6 are arranged between the corresponding lower wedge-shaped fixed blocks 7 and upper wedge-shaped fixed blocks 4 , and at this time, the central axes of adjacent vulcanized rubber plates 6 form a certain angle. Specifically, the central axes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com