Intelligent control casing valve applied to unbalanced drilling/completion

An underbalanced drilling and intelligent control technology, applied in wellbore/well valve devices, wellbore/well components, earthwork drilling, etc., can solve problems such as speeding up power consumption, improve efficiency and safety, and promote popularization Application, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

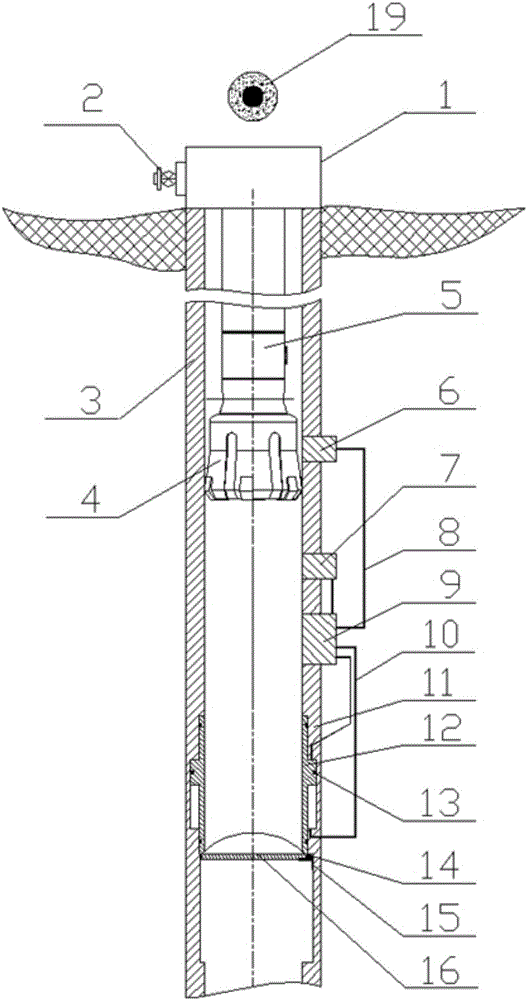

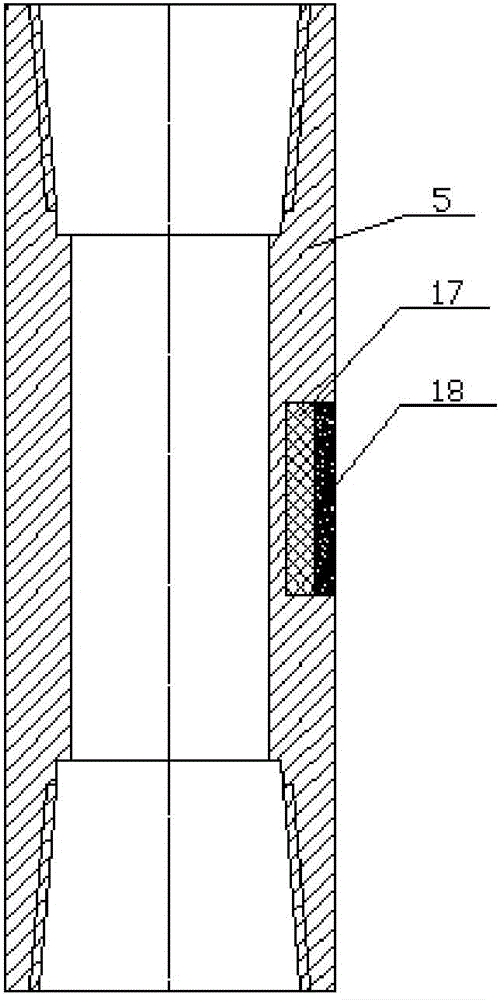

[0016] like figure 1 , 2 As shown: the intelligent control casing valve is connected by threads to become a part of the casing string 3, which includes a body 11, a valve plate 16, a battery pack 7, an RFID system, a hydraulic pump 9 controlled by the RFID system, and a hydraulic pump controlled by the hydraulic pump. 9 the inner cylinder liner 12 that controls its up and down movement; wherein, the RFID system includes a tag 17 and a reader 6, the tag 17 is embedded inside the smart sub 5, and its surface is covered with a wear-resistant layer 18, and the smart sub is connected to the drill string 4 Above; the reader 6 is installed on the upper part of the body 11, and the hydraulic pump 9 is connected to the reader 6 through the signal line 8; the lower part of the body 11 forms a cavity 2, and the two hydraulic lines 10 of the hydraulic pump 9 are respectively connected to the cavity 2 The upper and lower ends of the upper and lower ends; the inner cylinder liner 12 and th...

Embodiment 2

[0020] The difference from the structure of the intelligent control casing valve in Embodiment 1 is that the drill string 4 is not connected to the intelligent nipple 5, and the label exists in the form of a signal ball 19. The core of the signal ball 19 is a label 17, and the outside is formed of resin For the protective layer, the resin is preferably phenolic resin.

[0021] When in use, because the drill string 4 is not installed with the smart nipple 5 before going down the well, but during the rock breaking process, the formation pressure suddenly increases, and the casing valve valve plate 16 needs to be closed when the drill string 4 is pulled out. The lowermost end of the drill string 4 is tripped to the position between the valve plate 16 and the signal reader 6, and then the signal ball 19 is dropped from the wellhead 1. When the signal ball 19 falls to the vicinity of the reader 6 along the inner hole of the drill string 4, The reader 6 detects the label 17 to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com