Novel buffer impedance type silencer

An impedance type, muffler technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of differences, the muffler can not absorb noise, and the working principle has not changed, so as to achieve simple structure and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

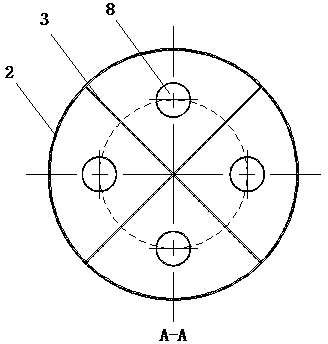

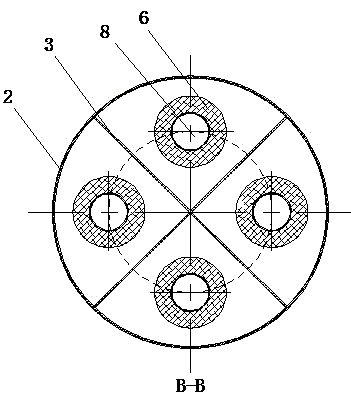

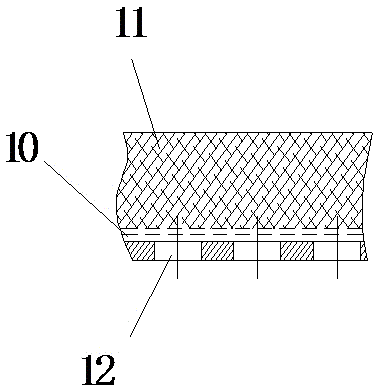

[0022] The new buffer resistance type muffler includes an expansion muffler chamber 2, the expansion muffler chamber 2 is cylindrical, one end of the expansion muffler chamber 2 is provided with an air inlet pipe 1, and the other end is provided with an air outlet pipe 9. A clapboard 3 is provided on the surface perpendicular to the center line of the air intake pipe 1 in the expanded anechoic chamber 2, a V-shaped buffer plate 15 is provided between the clapboard 3 and the air inlet 1, and an insertion pipe is provided on the clapboard 3. 8. The insertion tube 8 is cylindrical, and the insertion tube 8 is provided with a shock absorption hole 4 and a flow reduction hole 7. The insertion tube 8 is also provided with a sound-absorbing layer 6. The insertion tube 8 is connected to the inlet The central lines of the trachea 1 and the expanded anechoic chamber 2 are the same, and the expanded anechoic chamber 2 is provided with four sets of baffles, each set of baffles has four pie...

Embodiment 2

[0028] The new buffer resistance type muffler includes an expansion muffler chamber 2, the expansion muffler chamber 2 is cylindrical, one end of the expansion muffler chamber 2 is provided with an air inlet pipe 1, and the other end is provided with an air outlet pipe 9. A clapboard 3 is provided on the surface perpendicular to the center line of the air intake pipe 1 in the expanded anechoic chamber 2, a V-shaped buffer plate 15 is provided between the clapboard 3 and the air inlet 1, and an insertion pipe is provided on the clapboard 3. 8. The insertion tube 8 is cylindrical, and the insertion tube 8 is provided with a shock absorption hole 4 and a flow reduction hole 7. The insertion tube 8 is also provided with a sound-absorbing layer 6. The insertion tube 8 is connected to the inlet The central lines of the trachea 1 and the expanded anechoic chamber 2 are the same, and the expanded anechoic chamber 2 is provided with four sets of baffles, each set of baffles has four pie...

Embodiment 3

[0035] The new buffer resistance type muffler includes an expansion muffler chamber 2, the expansion muffler chamber 2 is cylindrical, one end of the expansion muffler chamber 2 is provided with an air inlet pipe 1, and the other end is provided with an air outlet pipe 9. A clapboard 3 is provided on the surface perpendicular to the center line of the air intake pipe 1 in the expanded anechoic chamber 2, a V-shaped buffer plate 15 is provided between the clapboard 3 and the air inlet 1, and an insertion pipe is provided on the clapboard 3. 8. The insertion tube 8 is cylindrical, and the insertion tube 8 is provided with a shock absorption hole 4 and a flow reduction hole 7. The insertion tube 8 is also provided with a sound-absorbing layer 6. The insertion tube 8 is connected to the inlet The central lines of the trachea 1 and the expanded anechoic chamber 2 are the same, and the expanded anechoic chamber 2 is provided with four sets of baffles, each set of baffles has four pie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap