Smoke machine strap bearing capacity testing device and testing method

A technology of a test device and a fog machine, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., to achieve the effect of simple structure, low labor intensity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and embodiments.

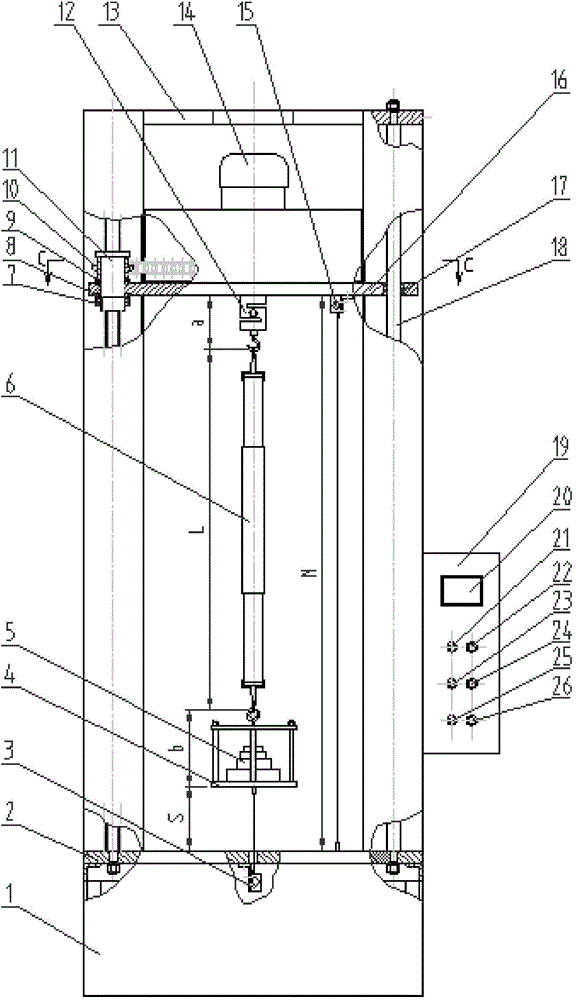

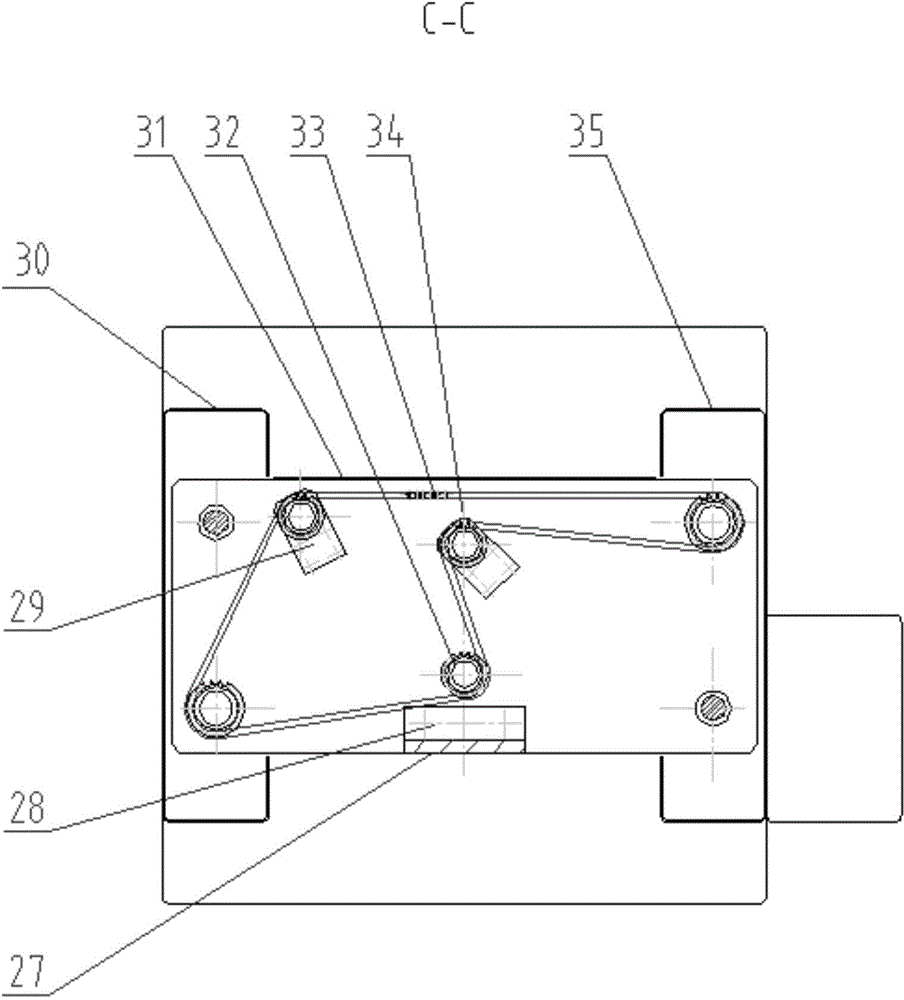

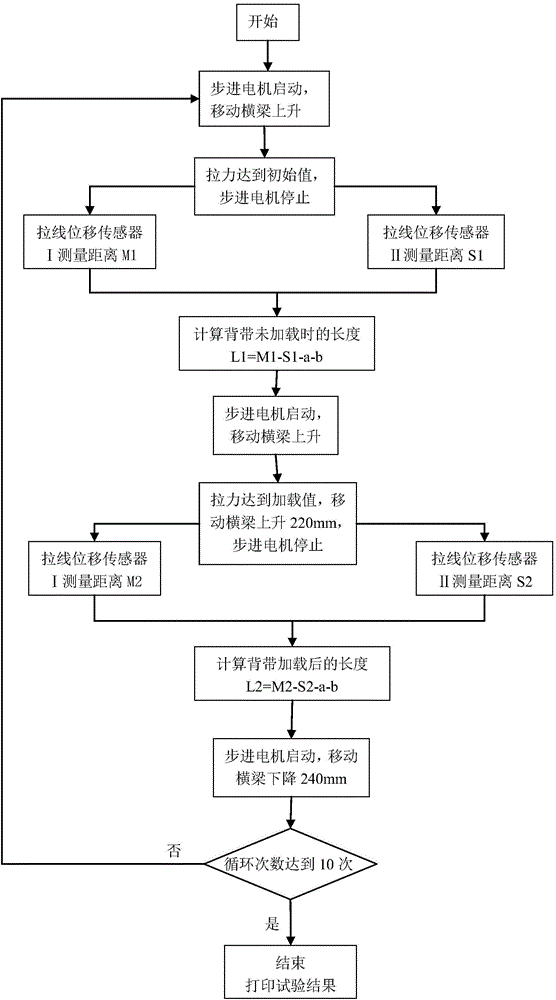

[0027] Such as Figure 1-Figure 2 As shown, the load-bearing test device for inspecting the quality of the back strap components of the fog machine includes a base 1 fixed on a level ground. The base 1 is provided with a lower fixing plate 2, and the lower fixing plate 2 is provided with a cable displacement sensor II 3 , Guide post 18, ball screw 11, left guard 30, right guard 35, upper fixing plate 13 through a pair of diagonally arranged guide posts 18 and a pair of diagonally arranged ball screws 11 and lower fixing plate 2 To connect, the ball screw 11 is provided with a nut sprocket 10, a plane bearing Ⅱ 9, a movable cross beam 16, a plane bearing Ⅰ 8, a shaft lock nut 7, and a guide sleeve 17 and a front baffle 27 are provided on the movable cross beam 16 , Rear baffle plate 31, tension sprocket Ⅰ 29, tension sprocket Ⅱ 34, tension sensor 12, pull wire displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com