COB type LED reflector design method

A design method and reflector technology, applied in the direction of instruments, calculations, special data processing applications, etc., can solve complex problems and the accuracy of calculation results needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

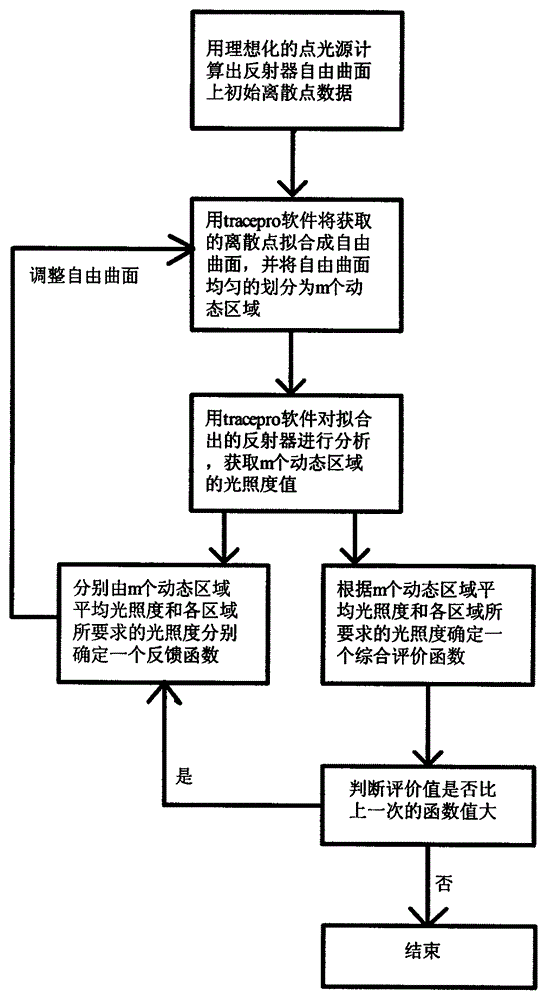

[0018] Such as figure 1 Shown is the flow chart of the design method involved in the present invention, and the concrete design steps involved are as follows:

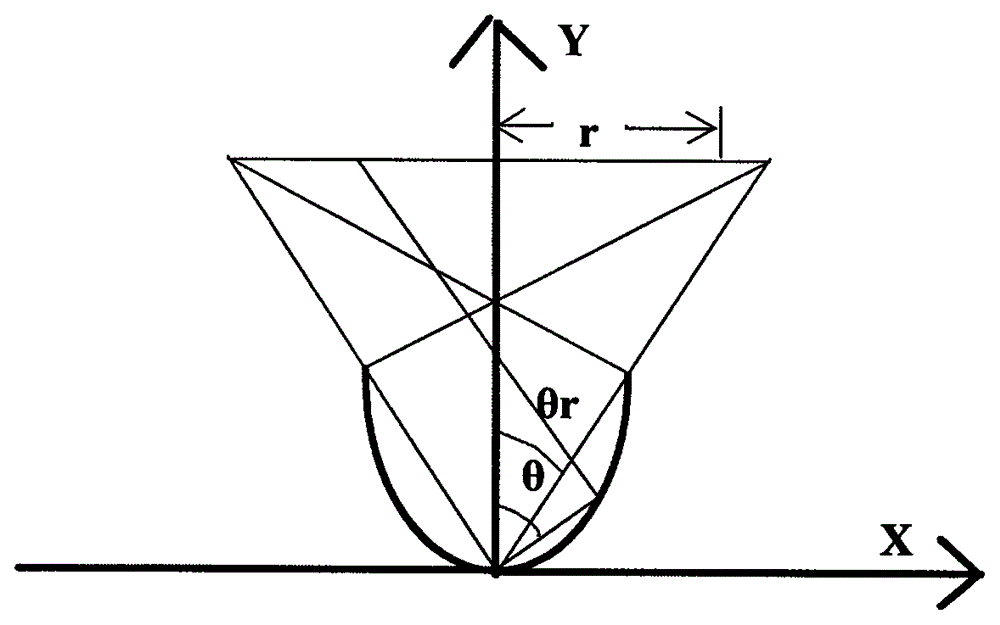

[0019] The first step of the design method involved in the present invention is to idealize the COB LED light source into a point light source, and its design principle diagram is as follows figure 2 As shown, according to the law of energy conservation, the relationship between the θ foot corresponding to the reflected part of the light and the radius r of the illuminated area is as follows:

[0020] ∫ 0 r E c · 2 πrdr = ∫ 0 θ r I · 2 π sin θdθ + ∫ θ π 2 I ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap