Automatic terminal crimping machine of RF antenna

A terminal punching machine and automatic technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problem of not realizing automatic combination terminal punching machine, etc., and achieve the effect of high degree of automation and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

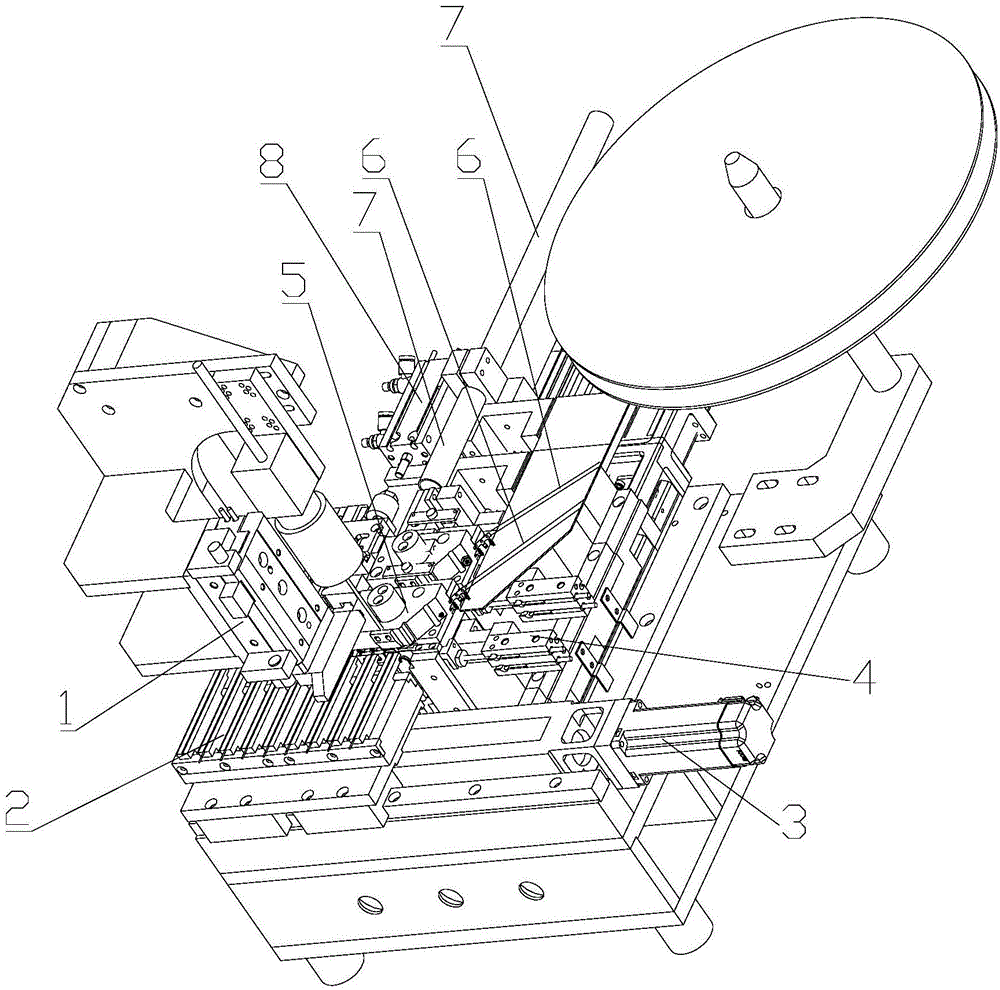

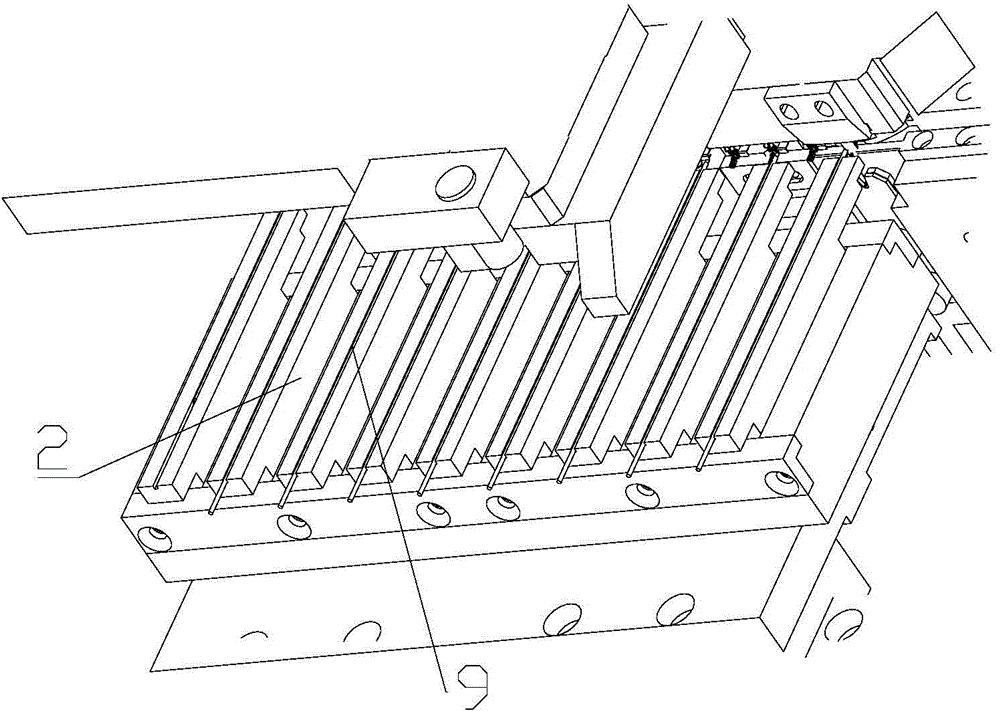

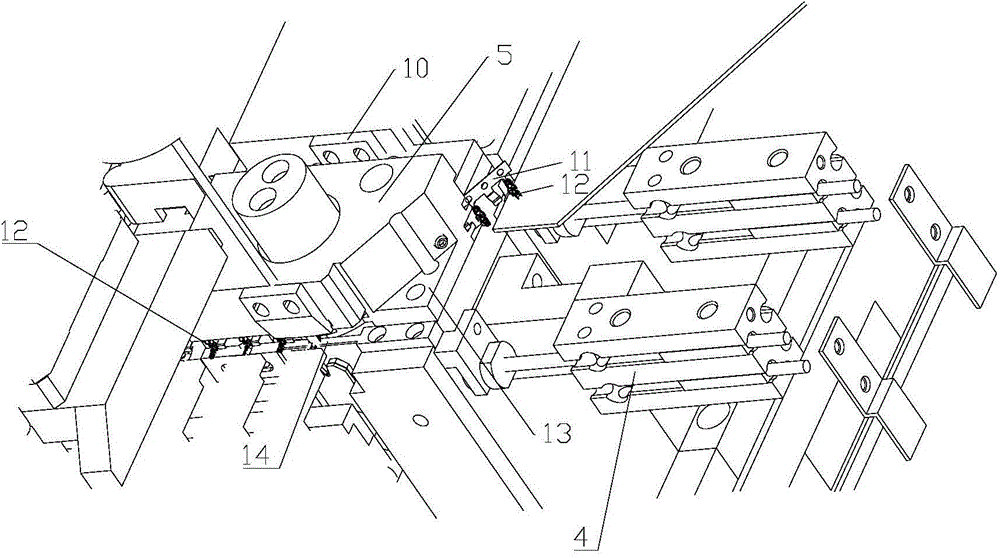

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] according to Figure 1-Figure 7 , the RF line automatic terminal punching machine, including a strip, is characterized in that the strip includes a strip feed section 6, a strip riveting section 6b and a strip discharge section 6c, and the strip discharge section 6c section is connected with the moving mechanism of the strip pin, and the strip riveting section is connected with the terminal cutting and bending mechanism. An integrally bent movable top block (not shown) formed by the third part 12c of the terminal; a vertically movable U-shaped block 20 for clamping the terminal is provided below the riveting section of the strip, so The terminal of the riveting section of the strip mentioned above accommodates the thread end. In fact, the thread end is mainly placed in the second part 12b of the terminal, and the whole body composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com