Redundant backup-based rope driving system and control method thereof

A redundant backup and control method technology, applied in the direction of motor speed or torque control, control system, electrical components, etc., can solve the problem of low tolerance of equipment failure rate, low tension of the rope, and easy reaction of the driving rope. In order to achieve the effect of reducing electromagnetic interference, improving system reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

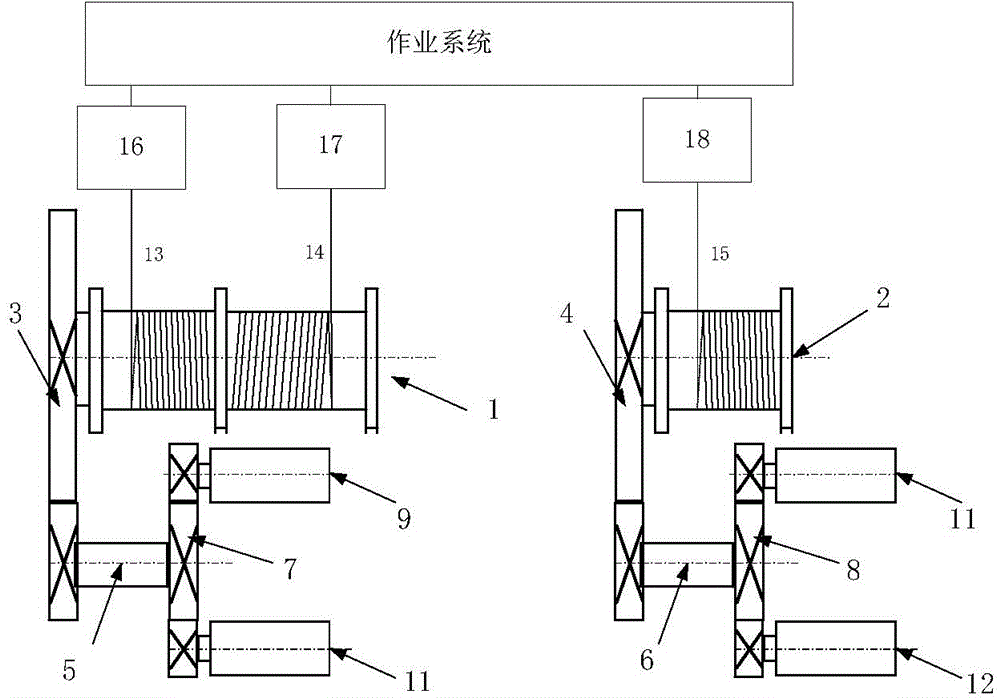

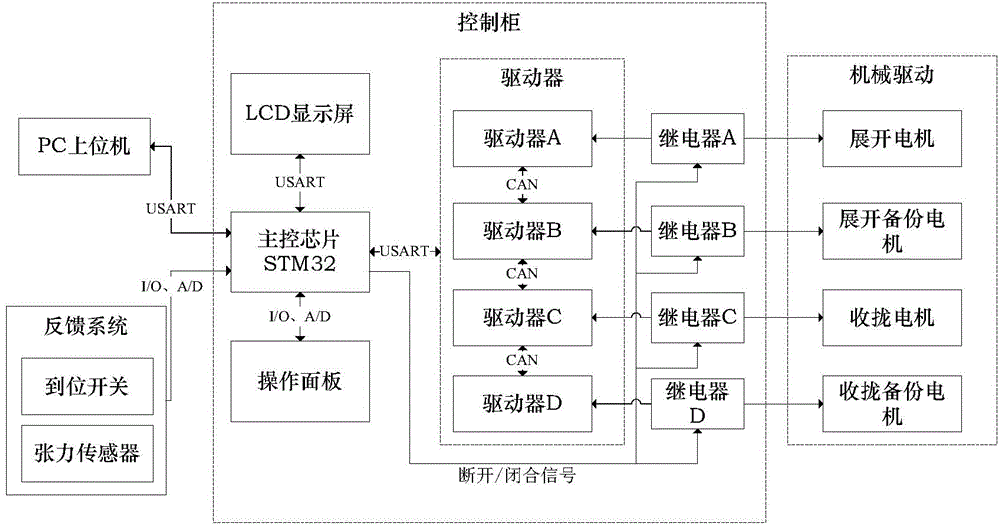

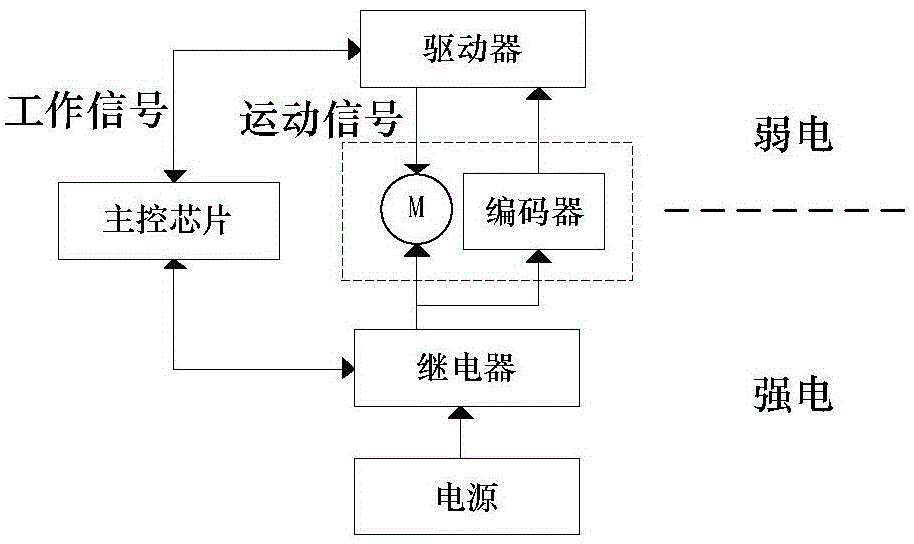

[0033] The present invention provides a redundant backup-based rope drive system and its control method. The mechanical structure of the rope drive system is as follows: figure 1 As shown, the mechanical parts of the rope drive system include: Unfolding wire roller 1, Gathering wire roller 2, Wire roller gearbox A3, Wire roller gearbox B4, Motor gearbox A5, Motor gearbox B6, Backup motor gearbox A7, backup motor gearbox B8, unfold motor 9, expand backup motor 10, draw in motor 11, draw in backup motor 12, expand rope A13, expand rope B14 and draw in rope 15.

[0034] The unfolding rope A13, the unfolding rope B14 and the gathering rope 15 are called driving ropes, and each driving rope is respectively equipped with a tension sensor A16, a tension sensor B17 and a tension sensor C18. One end of the unrolling rope A13 is connected to the left side reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com