Container valve for gas extinguishing agent steel cylinder

A gas fire extinguishing agent and container valve technology, which is applied in valve details, safety valves, balance valves, etc., can solve problems such as misspraying of fire extinguishing agent steel cylinders, affecting the normal spraying of gas fire extinguishing agents, and misoperation of starting container valves. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

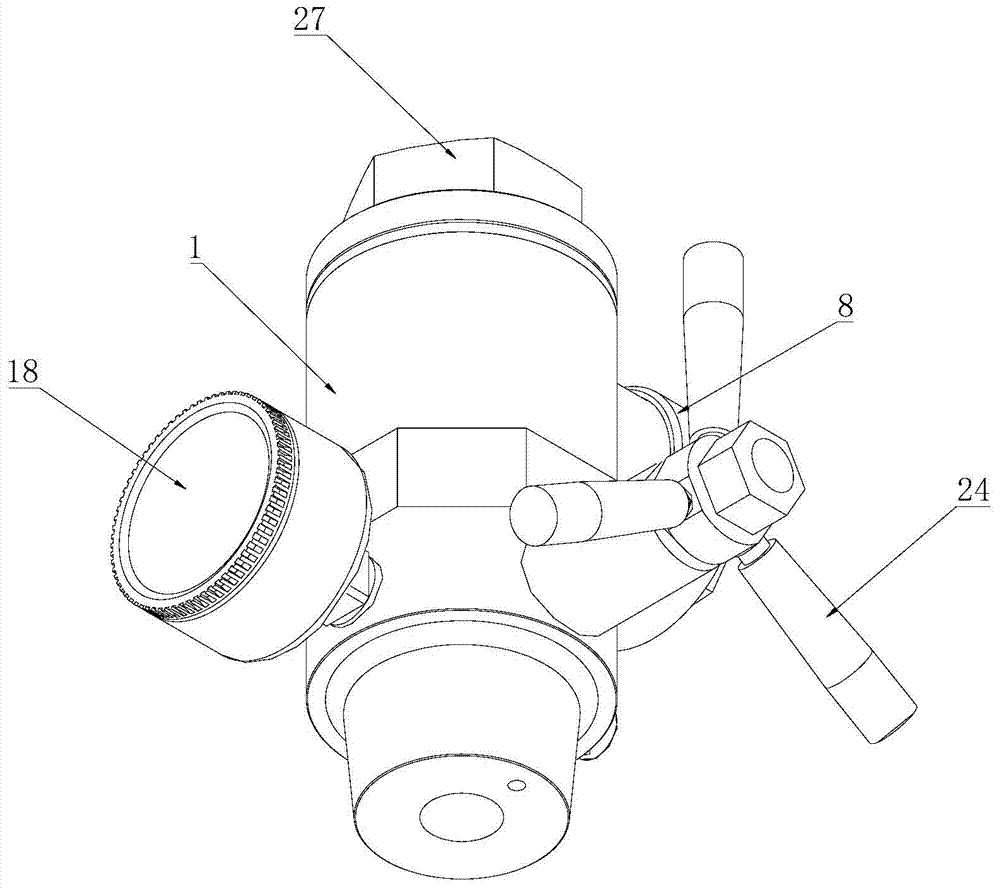

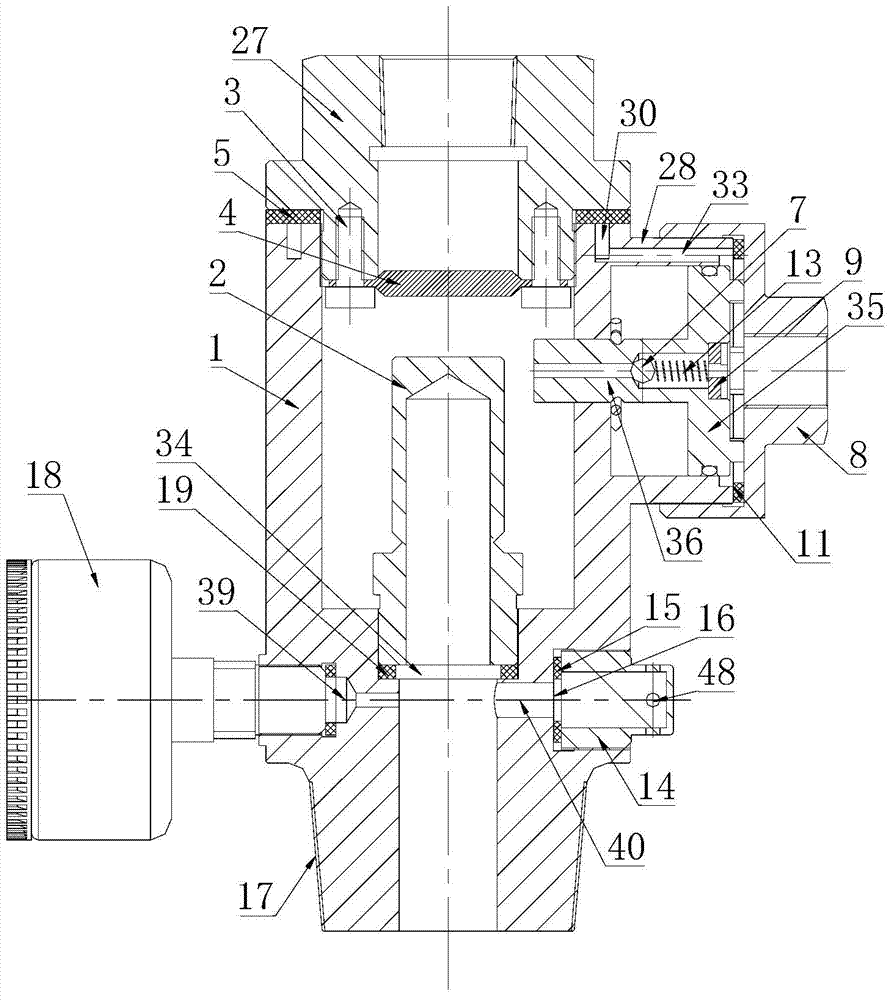

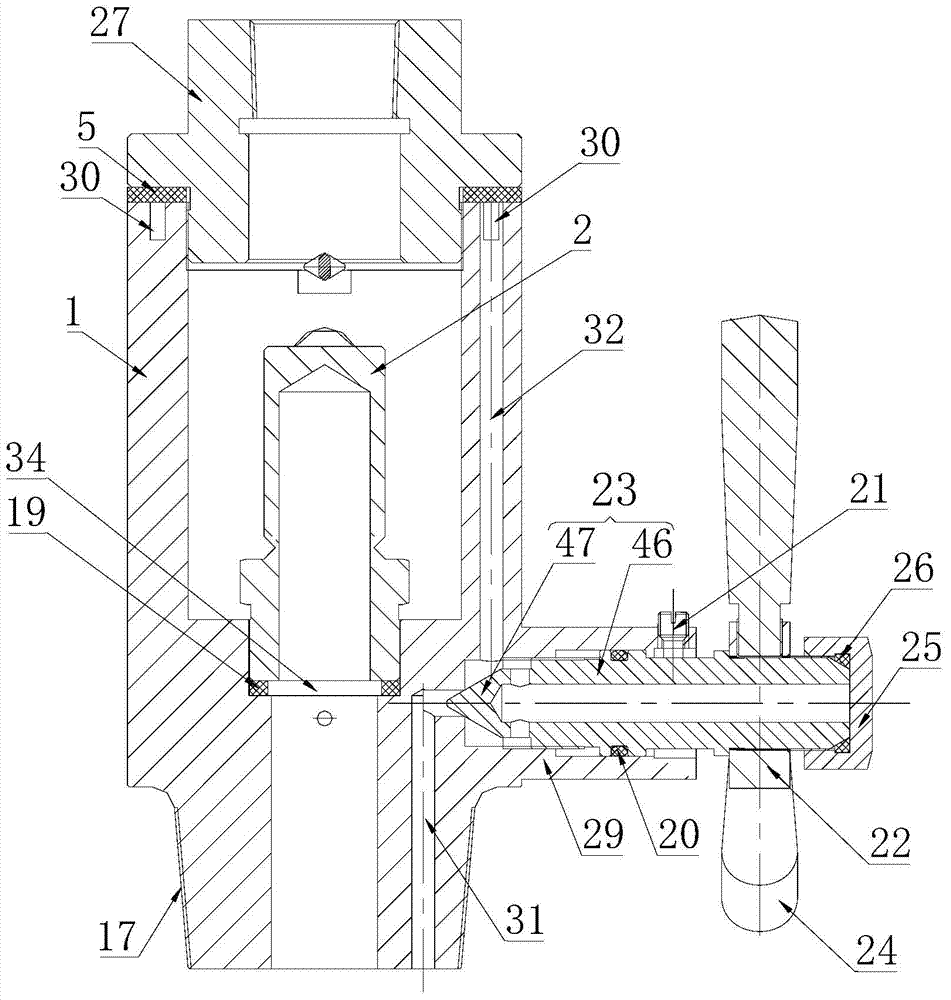

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Please refer to the attached Figure 1-13 , with Figure 1-13 It is a structural schematic diagram of the first embodiment of the container valve, a container valve for a gas fire extinguishing agent cylinder, including a valve body 1, a joint 27 installed on the top of the valve body 1, and a pressure cap 8 connected to the right side of the valve body 1 And the piston rod 10 is connected to the pressure gauge 18 on the left side of the valve body 1 and connected to the handle 24 on the front side of the valve body 1 .

[0034] The valve body 1 is hollow up and down, and consists of an upper cylindrical cavity and a lower conical cavity. The right side of the upper cylindrical cavity is convexly provided with a first circular cavity 28, and the first circular cavity 28 communicates with the upper cylindrical cavity; the front side is convexly provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com