Preparation method for oxidized vanadium-titanium dioxide sol, and application method thereof

A technology of titanium dioxide and a manufacturing method, which is applied in the field of photocatalyst sol manufacturing, can solve problems such as inconvenient use of photocatalyst sol, and achieve the effects of prolonging recombination time and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

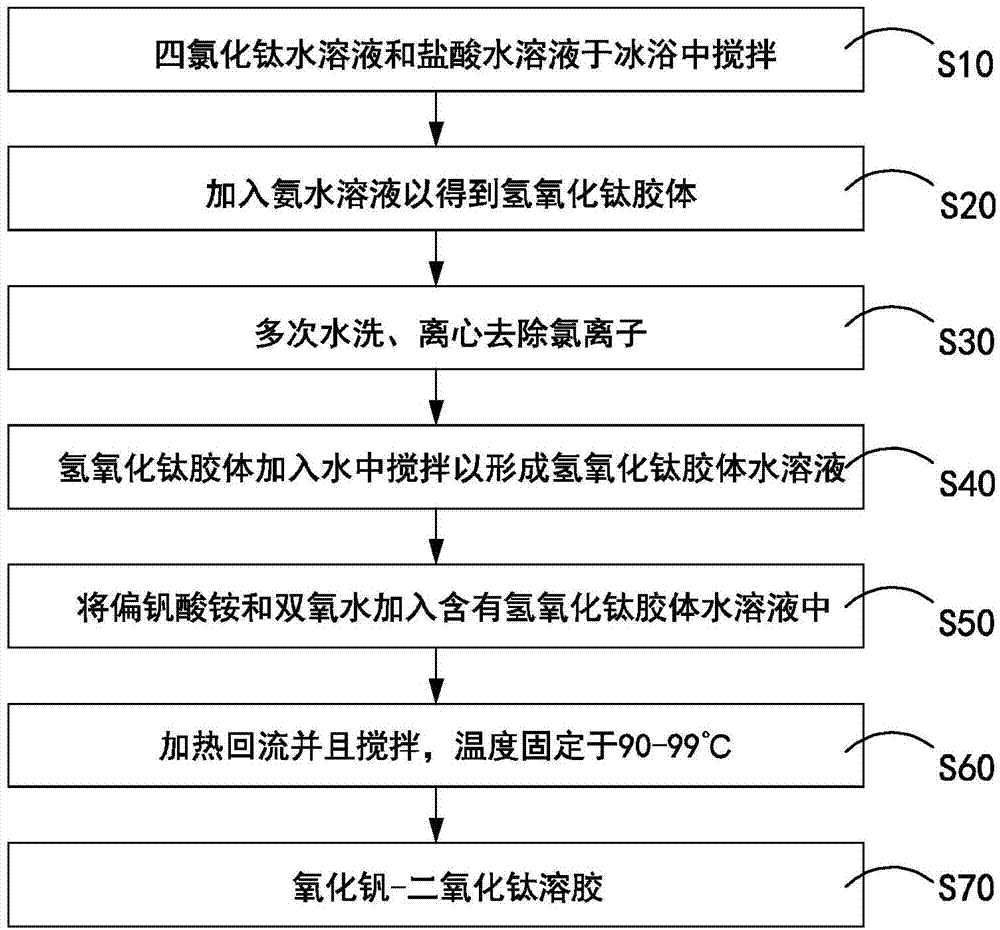

Method used

Image

Examples

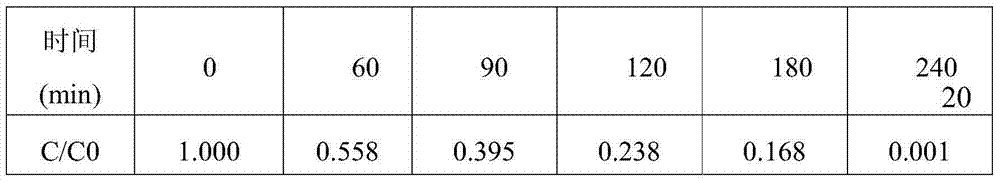

Embodiment 1

[0024] In an ice bath at 0°C, slowly drop titanium tetrachloride aqueous solution into hydrochloric acid aqueous solution to make a 5 molar concentration (5M), then slowly add 30% ammonia solution to the aforementioned solution, and keep stirring until The pH value of the solution is 8.5. After repeated washings, until the concentration of chlorine is lower than 10ppm, it is filtered to obtain a filter cake, which is naturally dried at room temperature. In order to control the solid content of titanium dioxide in the solution at 1%, take Add a certain amount of filter cake to distilled water, and add ammonium metavanadate and hydrogen peroxide, the weight ratio of titanium dioxide is 1 to 100, and the weight ratio of ammonium metavanadate to titanium dioxide is 0.5 to 100. In the type bottle, connect the condenser tube, heat and cook at 95°C for 12 hours to obtain nano-sized titanium dioxide sol.

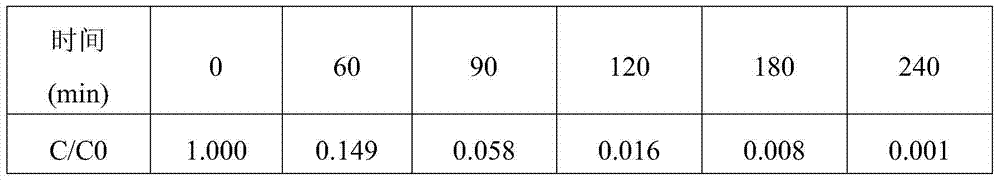

Embodiment 2

[0026] Same as Example 1, except that the weight ratio of ammonium metavanadate to titanium dioxide is 2:100.

Embodiment 3

[0028] Same as Example 1, except that the weight ratio of ammonium metavanadate to titanium dioxide is 0.5 to 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com