A fan feeding dust separator

A technology of dust separator and cyclone separator, which is applied in the direction of the device where the axial direction of the swirl flow can be reversed, the swirl flow device, etc., which can solve the problems of inability to remove dust from the material and achieve an excellent dust collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

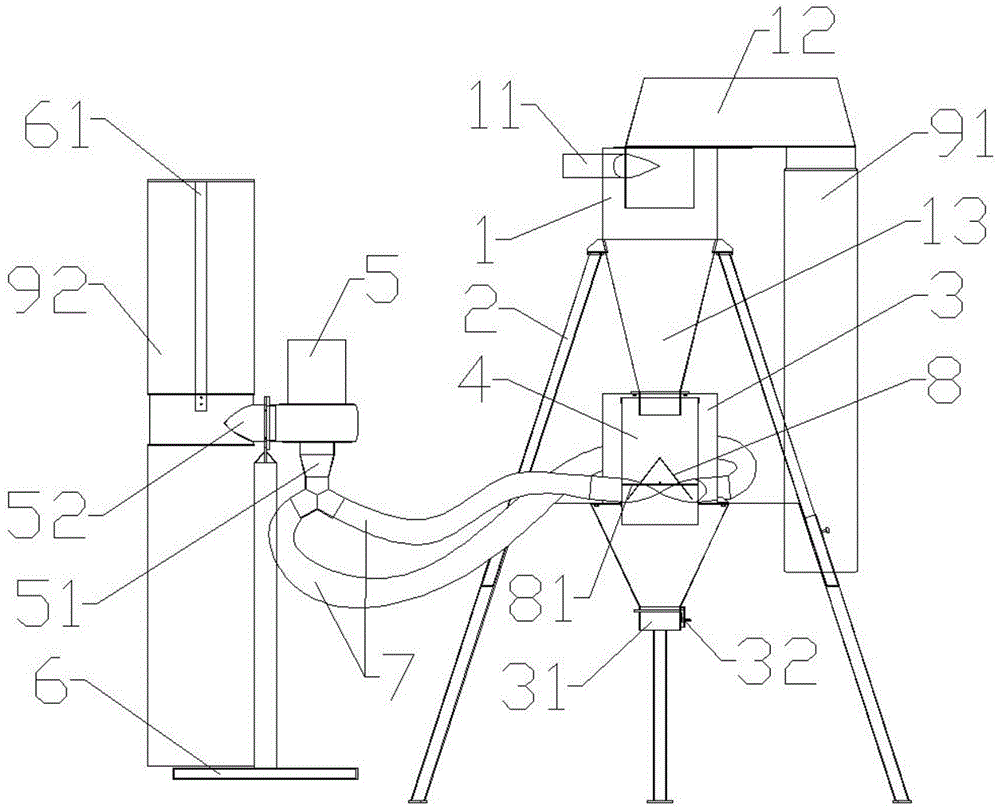

[0029] refer to figure 1 , is a schematic structural view of the fan feeding dust separator of the present invention. As shown in the figure, the dust separator includes a cyclone separator 1, a cyclone bracket 2, a dust collector outer bucket 3, a dust collector mesh bucket 4, a dust collection fan 5, a dust collection bag support 6, and a dust collection Bags 91 and 92. in,

[0030] The upper side of the cyclone separator 1 is provided with a fan feeding pipeline inlet 11, which is used to connect the fan feeding pipeline to feed materials into the cyclone separator 1, and the upper end of the cyclone separator 1 is connected with a dust discharge device. Channel 12, and another outlet of the dust discharge channel 12 is connected with a dust bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com