Shielding method of complex spraying shielding region of spacecraft structural plate

A spacecraft structure and complex technology, applied in the direction of surface coating liquid devices, coatings, spraying devices, etc., can solve the problems of unsuitable spacecraft structural plates, etc., to reduce redundant materials, meet high reliability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

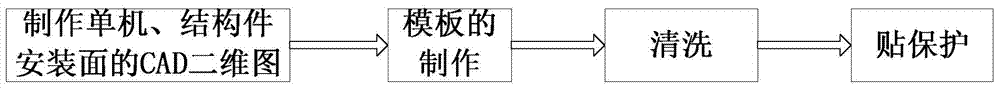

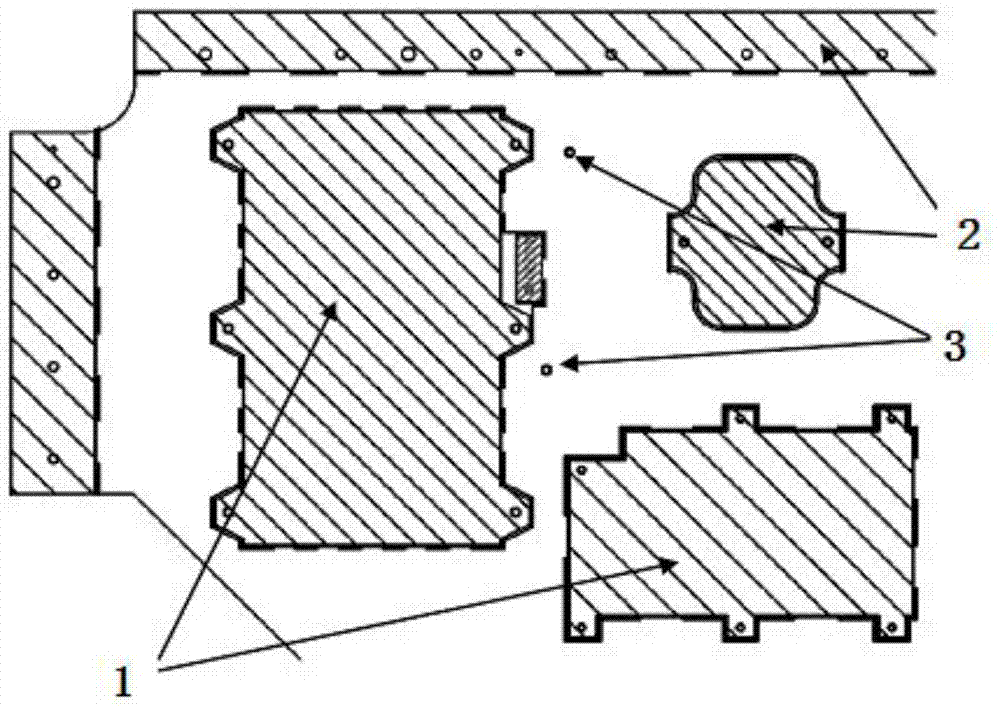

[0047] First, coordinate with the designers to obtain the 3D PROE diagram of the stand-alone and structural parts in the corresponding area of the spacecraft structural plate, and project it to the one-way 1:1, obtain the outer contour of the installation surface of the stand-alone and structural parts and the projection of the installation hole, and draw CAD Two-dimensional map. According to the design requirements, the complex outer contour of the installation surface of the stand-alone machine and structural parts is expanded by 1-2mm on one side. Use HP DESIGNJET plotter for 1:1 drawing. Clean the surface of the product with white silk cloth or degreasing white gauze dipped in acetone or absolute ethanol. Remove the smooth film on the back of the protective formwork, position it according to the fastening screws, and carry out spraying and masking. Use a squeegee to roll along the edge of the masking film to ensure that the edge of the masking film is firmly attached. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com