Labeler

A labeling machine and labeling technology, applied in the field of machinery, can solve the problems of high technical requirements for workers, high labor intensity, and low production efficiency, and achieve the effect of low technical requirements for operation, high production efficiency, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following combination Attached picture Embodiments of the invention are described in detail, but the invention can be practiced in many different ways as defined and covered by the claims.

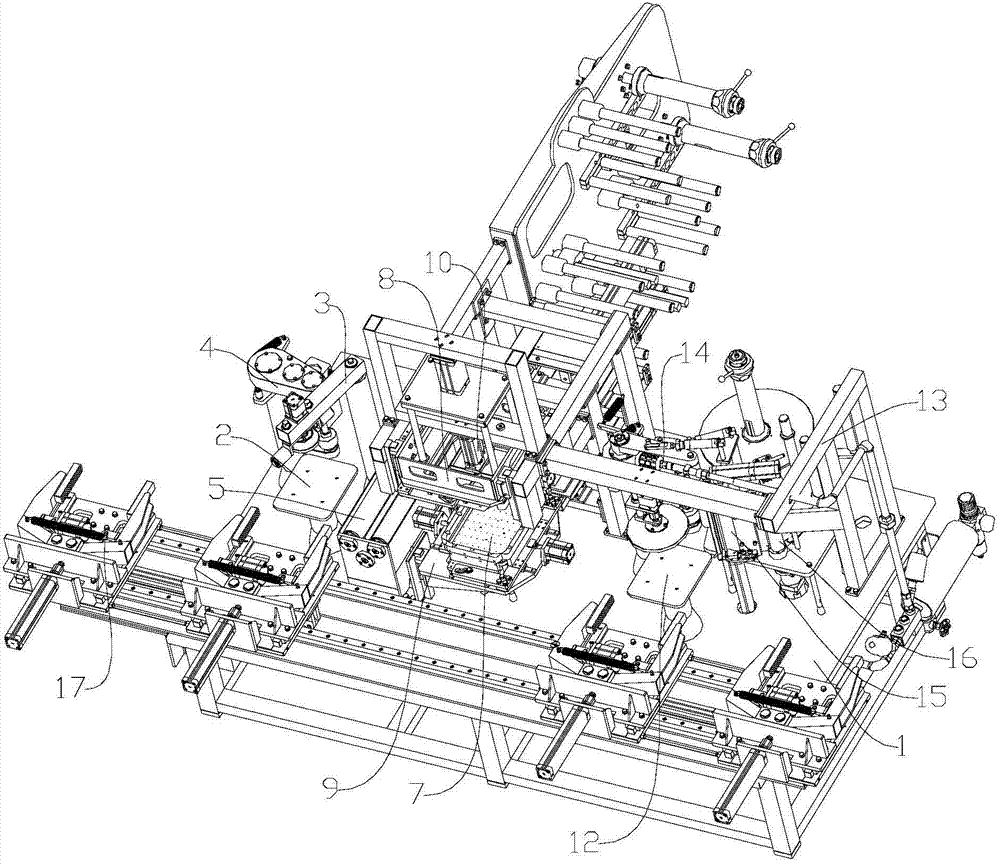

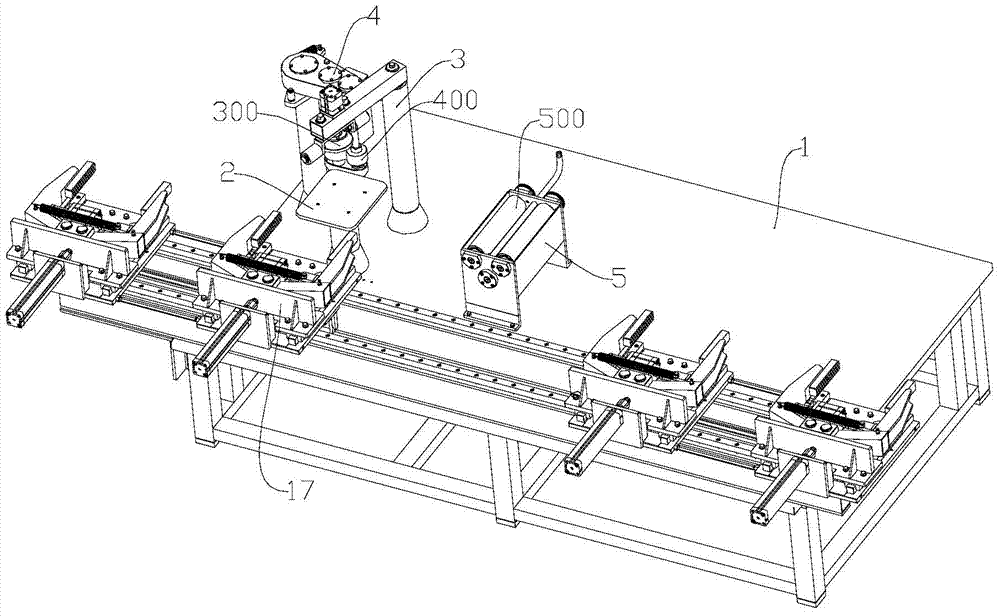

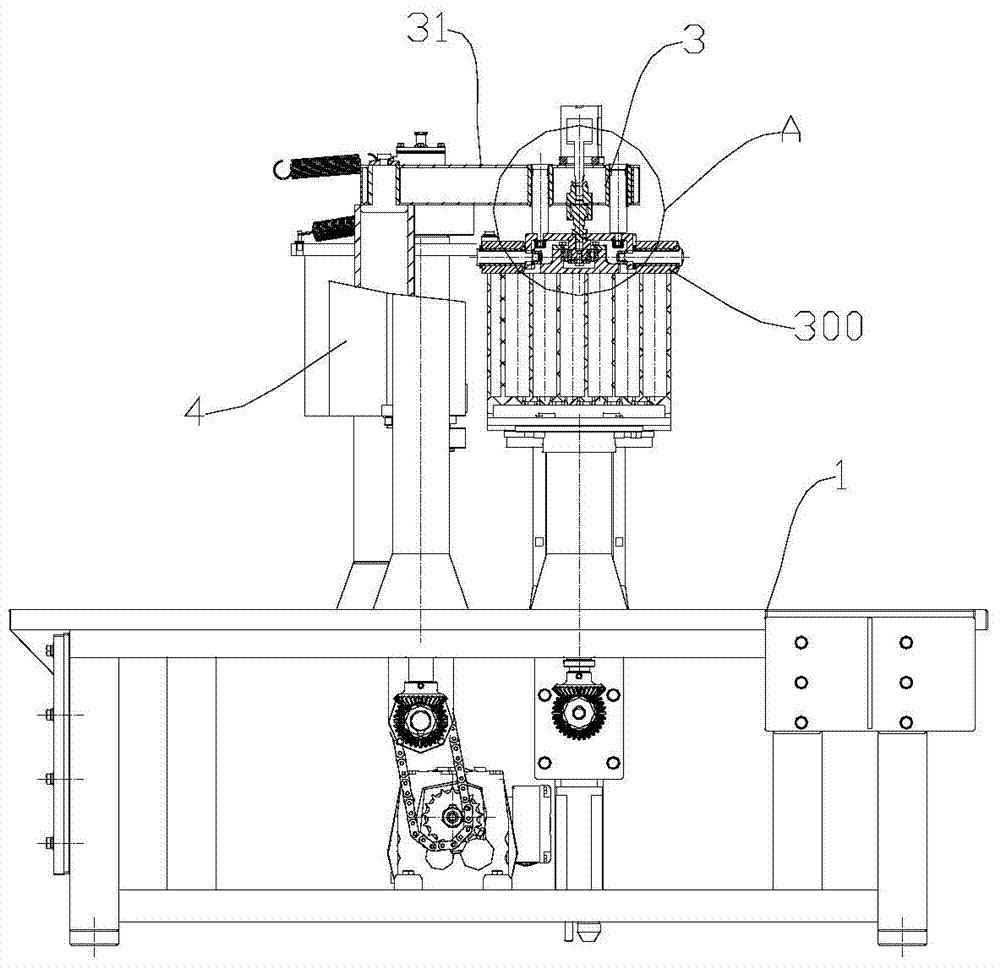

[0057] Such as figure 1 As shown, the present invention discloses a labeling machine, which includes: a workbench 1, a gluing mechanism, a labeling and forming mechanism for the upper and lower surfaces, a labeling and forming mechanism for the ring surface, a handling mechanism, and a gluing mechanism , the upper and lower surface labeling and forming mechanism, the annular surface labeling and forming mechanism, and the handling mechanism are all arranged on the workbench 1; the gluing mechanism is used for the upper surface and the lower surface of the columnar labeling object to be glued , and the ring surface are glued separately; the upper and lower surface labeling and forming mechanisms are used to label the upper surface and the lower surface of the labeling object ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap