Automatically opening and closing leakage-proof nozzle cap

An automatic opening and closing technology, applied in the field of containers, can solve the problems of liquid leakage, easy contamination of beverages, inconvenient movement and portability, etc., and achieve the effect of easy portability and easy bottle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

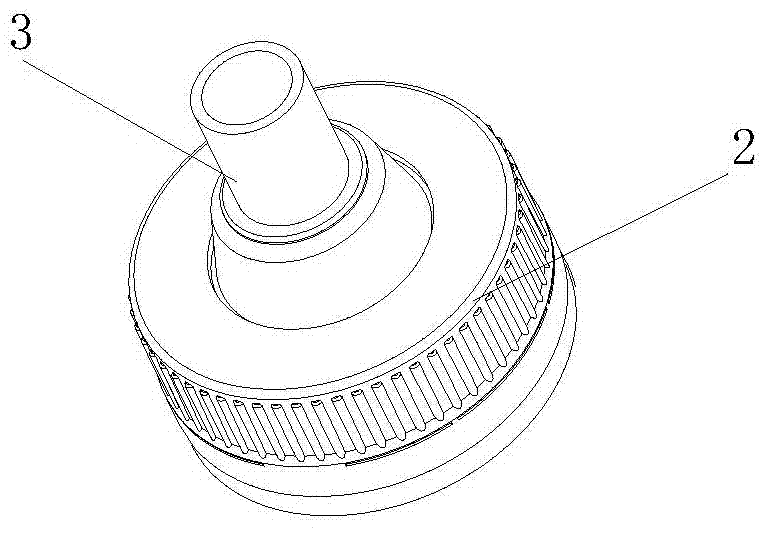

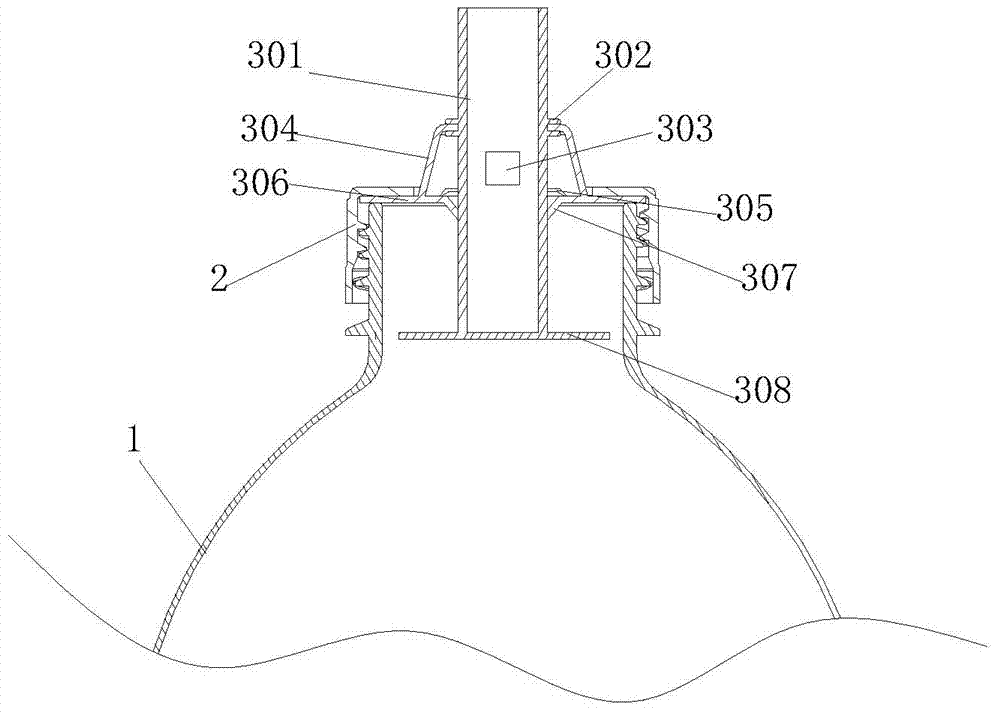

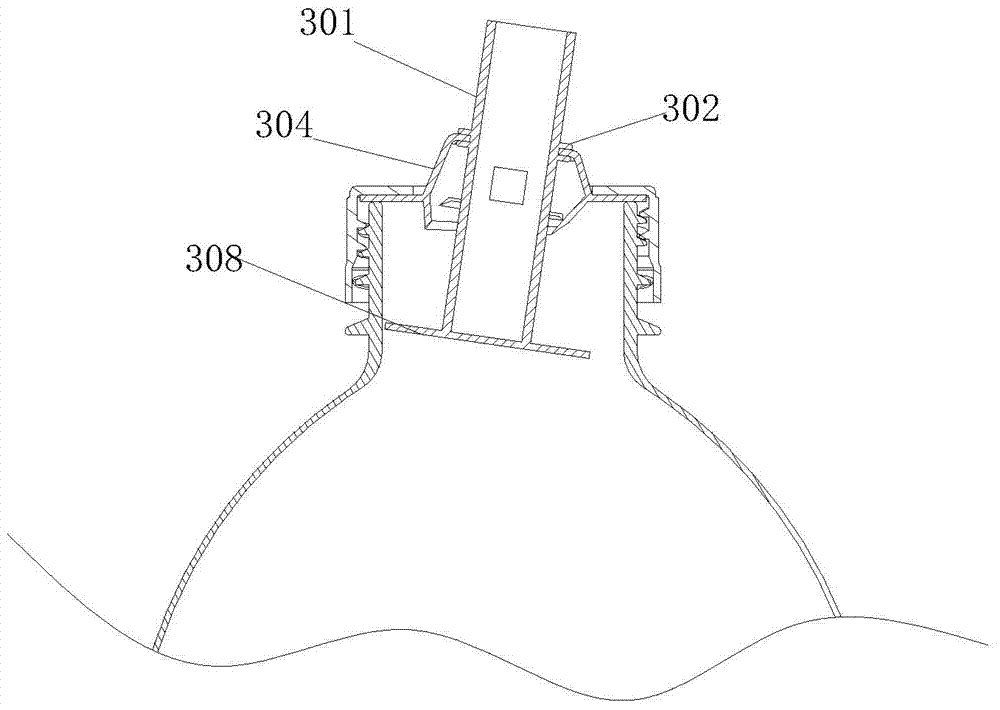

[0015] Example 1: refer to Figure 1-Figure 4 As shown; to provide a leak-tight cap that can be automatically opened and closed, including a screw cap 2, the top surface of the screw cap 2 is provided with a hole 201, and the A water outlet assembly that can automatically discharge water and can be automatically closed after loosening; the water outlet assembly includes a first frustum member 3 pressed against the bottle mouth through the bottle cap, and the first frustum member 3 has a connection with the bottle mouth. The bottom plate 306 with the top surface abutting, the upper surface of the bottom plate is provided with a hollow frustum 304 extending from the bottle cap hole, the top surface of the hollow frustum 304 is provided with an annular opening edge 309, the bottom of the bottom plate 306 is The lower surface is provided with an inverted conical water outlet hole 307 that communicates with the hollow frustum, and also includes a top surface passing through the ho...

Embodiment 2

[0018] Embodiment 2: refer to Figure 5-Figure 8 The water outlet assembly includes a second frustum member 5 pressed against the bottle mouth through the bottle cap, and the second frustum member 5 has a bottom plate 502 abutting against the bottle mouth. The upper surface is provided with a hollow conical frustum 501 protruding from the bottle cap hole 201, the top surface of the hollow conical frustum 501 is provided with a short pipe 506 extending upward, and the lower surface of the bottom plate 502 is provided with a The second inverted conical water outlet hole 503 connected with the hollow cone frustum 501 is also provided with an empty cylinder 504 on the lower surface of the bottom plate which can be clamped on the side wall of the inner hole of the bottle neck. A water outlet hole 505;

[0019] It also includes a short pipe passing through the hollow frustum, the second inverted conical water outlet hole and the first water outlet hole, and a second suction pipe me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com