Vertical lifting and conveying system for open-pit mine trucks

A vertical lifting and transportation system technology, used in transportation and packaging, lifting equipment in mines, etc., can solve the problems of difficult to greatly improve transportation capacity and efficiency, increase the wear and tear of mining vehicles, and reduce the life of vehicles. Safety and reliability, reduced exhaust emissions, enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

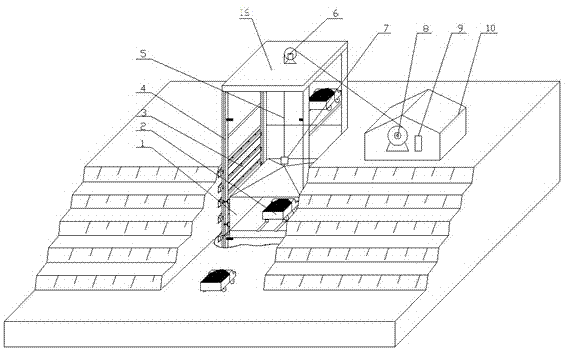

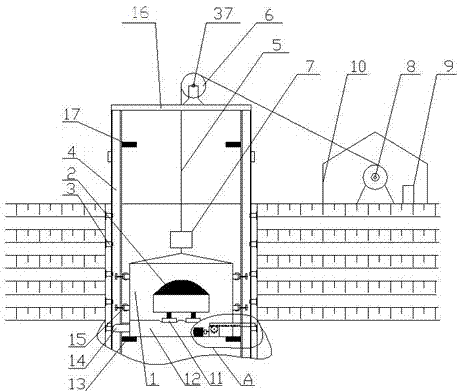

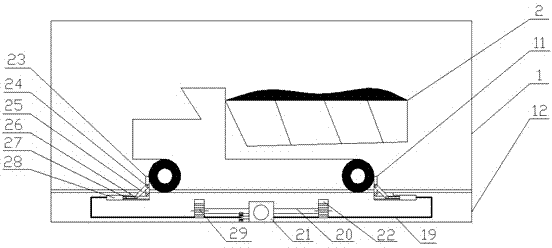

[0024] Such as figure 1 and figure 2 As shown, the vertical lifting transportation system of the open-pit mining vehicle includes a vertical lifting guide system, a lifting container 1, a brake 14, a steel wire rope 5, a sky wheel 6, a hoist 8 and a tension balance device 7, and the steel wire rope 5 is Multiple, hoist 8 is set in the hoisting machine room 10 on the ground surface, the vertical hoisting guide system includes vertical I-shaped steel track 4, horizontal convex-shaped steel 3 and roof 16, and horizontal convex-shaped steel 3 is arranged in the horizontal direction, such as Figure 8 Shown, be fixed on both sides rock wall 38 by bolt 35, vertical I-shaped steel track 4 vertical direction is connected with horizontal convex-shaped steel 3, top plate 16 is arranged on the top of vertical I-shaped steel track 4, vertical I-shaped steel track 4 Shaped steel trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com