A sunken roll preheating method with sufficient preheating and uniform heating

A technology of uniform heating and submerged rollers, applied in hot dip plating, coating, metal material coating, etc., can solve the problem of uneven heating of roller bearings, bushings, insufficient preheating of rollers, and concave surface of galvanized sheets. pits and other problems, to achieve the effect of improving the surface appearance quality, reducing surface scratches, and uniform preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

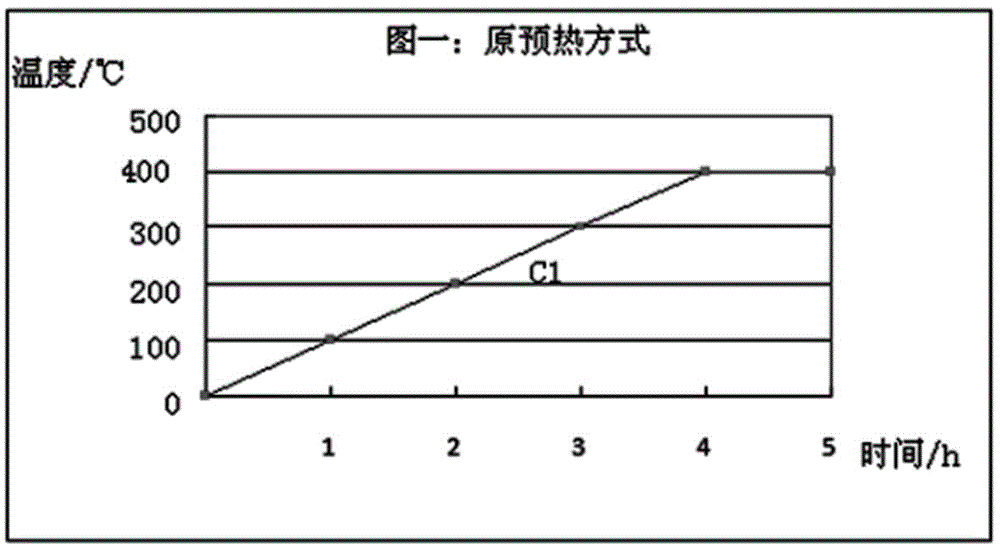

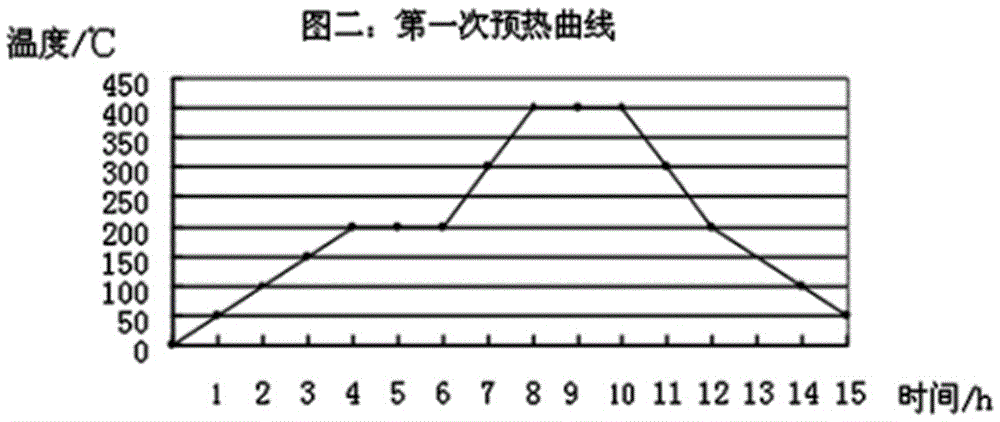

[0025] The sunken roller preheating box of the present invention is an upside-down quadrangular truss-shaped box body, with multiple groups of heating wires distributed on both sides of the box body, no heating wires at the bottom, and an open top. Due to the short preheating time and the structure of the preheating box, after one preheating, the local temperature of the box reaches the set temperature of 400°C (the highest temperature), the temperature of the bottom and top of the box is 30-50°C lower than that of the middle part, and the middle part of the sinking roller The temperature of the roller surface is 340-360 degrees, but the temperature of the bottom bearing and the top roller surface is only 310-330 degrees Celsius. There is a temperature difference between the bearings and the roller surface of the upper and lower rollers.

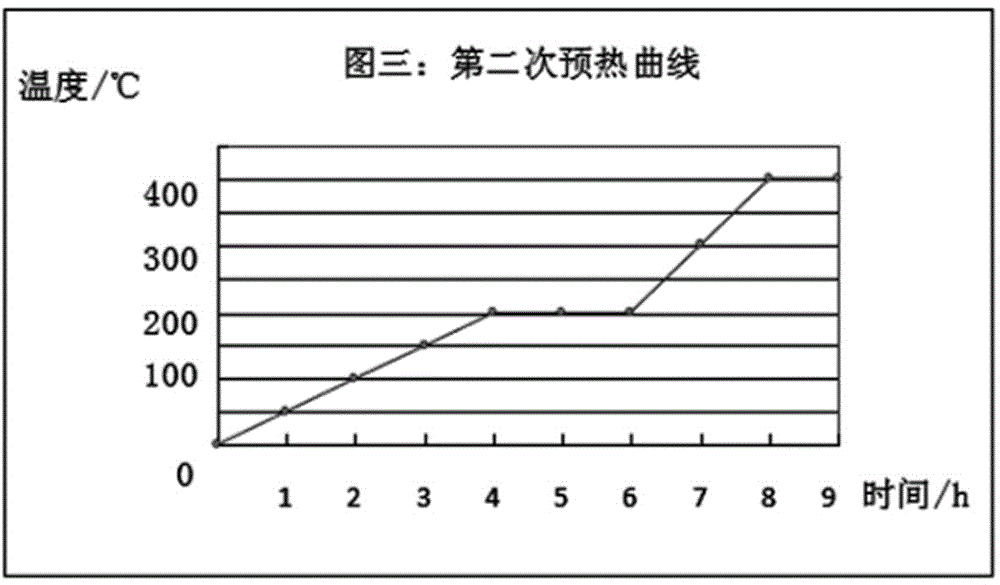

[0026] During the second preheating, the roller after the first preheating is rotated by 90°C, and the part that has not been heated above 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com