Baffle-plate steam admission structure of steamer type tire vulcanizing machine

A technology of tire vulcanization and machine block, which is applied in the field of steam intake structure of the baffle plate of steamer type tire vulcanizer, which can solve the problems that cannot meet the production requirements of high-performance tires, affect the quality of tires, and affect the vulcanization effect of tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The steam intake structure of the baffle plate of the steamer type tire vulcanizing machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

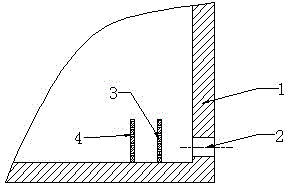

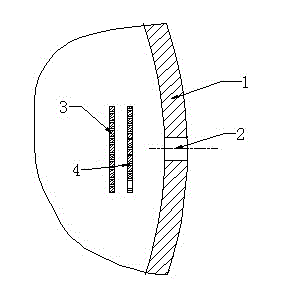

[0011] As shown in the figure, the baffle steam intake structure of the steamer type tire curing machine of the present invention includes a steam inlet 2 arranged on the side wall of the lower part of the tire curing machine body 1, and a piece of air hole arranged inside the tire curing machine body 1 The central part of the baffle 3 is directly facing the steam inlet 2, so the direction and dispersion form of the steam flow can be changed through the set baffle, so that the overall temperature difference of each point of the mold at different positions is greatly reduced during the preheating process. In particular, the air holes set on the baffle can make the mold behind the baffle receive part of the steam, thereby increasing its uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com