Hot-dip galvanizing pretreatment device

A pre-treatment, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of flux failure, low drying efficiency, etc., to achieve uniform preheating temperature, convenient The effect of popularizing application and avoiding local high temperature and local low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

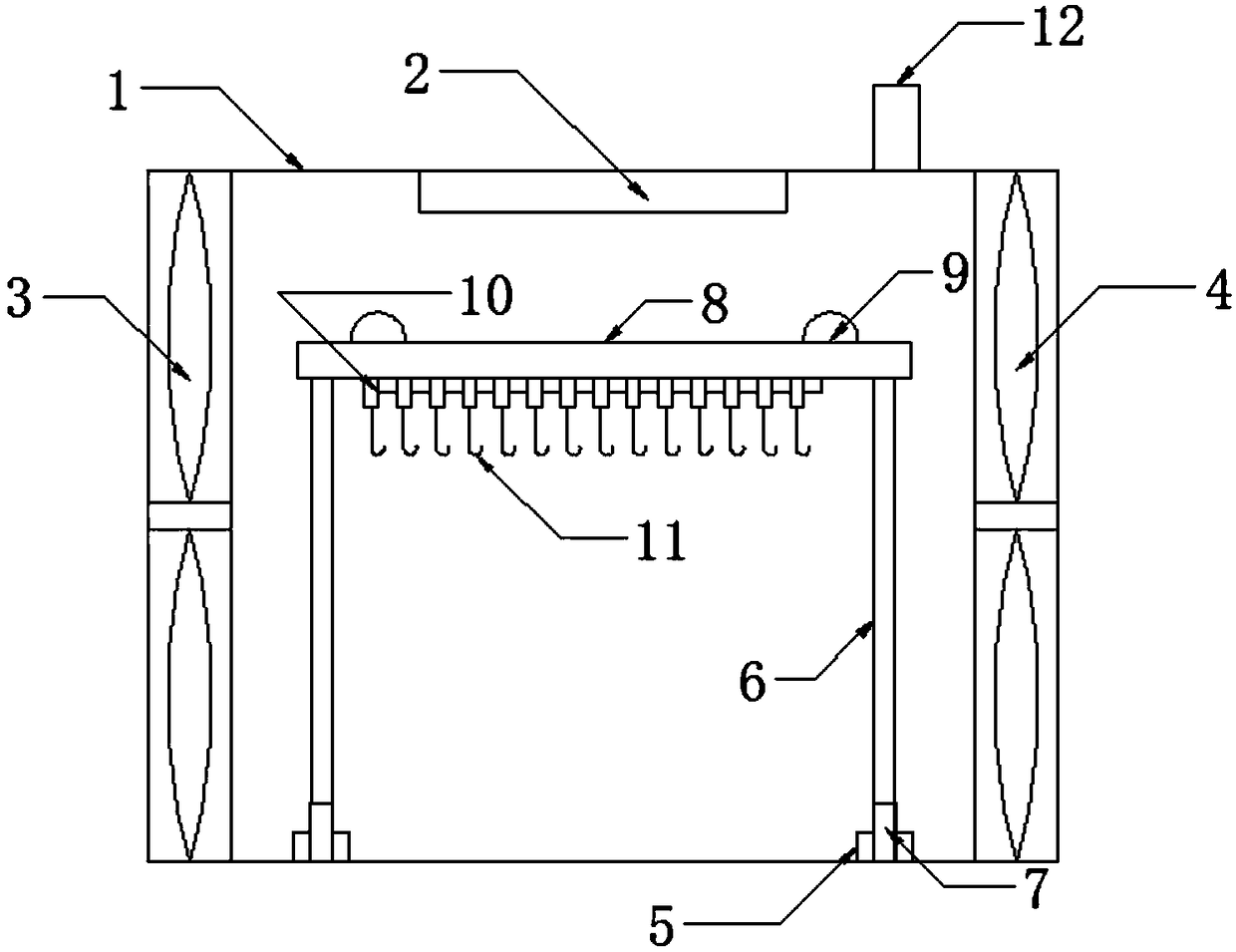

[0017] Such as figure 1 As shown, a kind of hot-dip galvanizing pretreatment equipment of the present invention includes a heating chamber 1, a heating mechanism 2, a first fan 3, a second fan 4, a rail 5, a frame 6, a wheel 7, a fixing plate 8, and a suspension ring 9. Chain transmission mechanism 10, material hook 11, moisture discharge port 12;

[0018] The top of the heating chamber 1 is provided with a heating mechanism 2, and the left and right side walls of the heating chamber 1 are provided with a first fan 3 and a second fan 4 oppositely arranged, and the blades of the first fan 3 and the second fan 4 all extend to the heating The upper and lower ends of the chamber 1, and the top of the heating chamber 1 are also provided with a moisture discharge port 12;

[0019] The bottom end of the heating chamber 1 is provided with a rail 5, and the wheels 7 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com