Arc preheating method for automatic butt welding of T91 pipes

A technology of automatic welding and automatic welding machine, which is applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

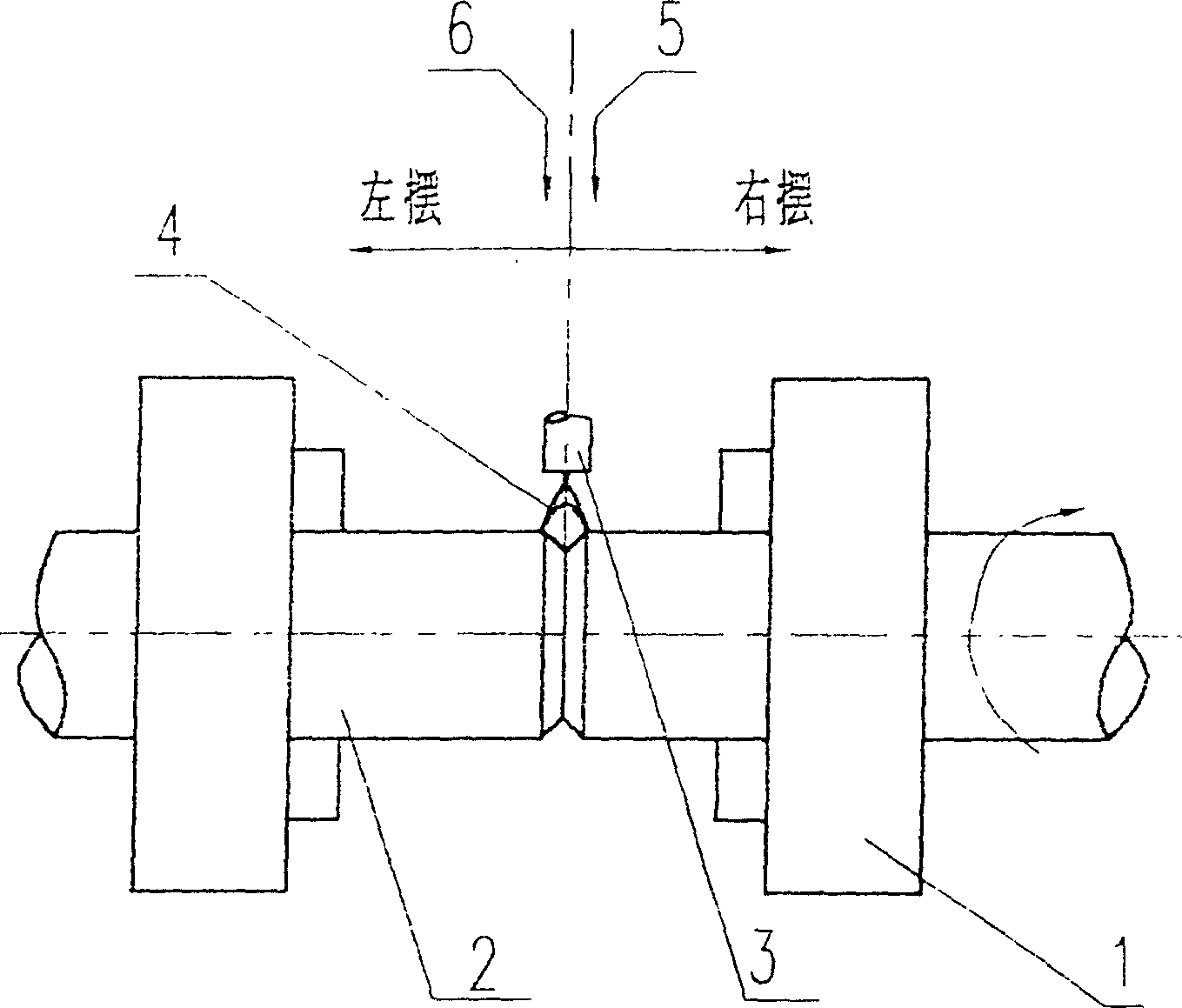

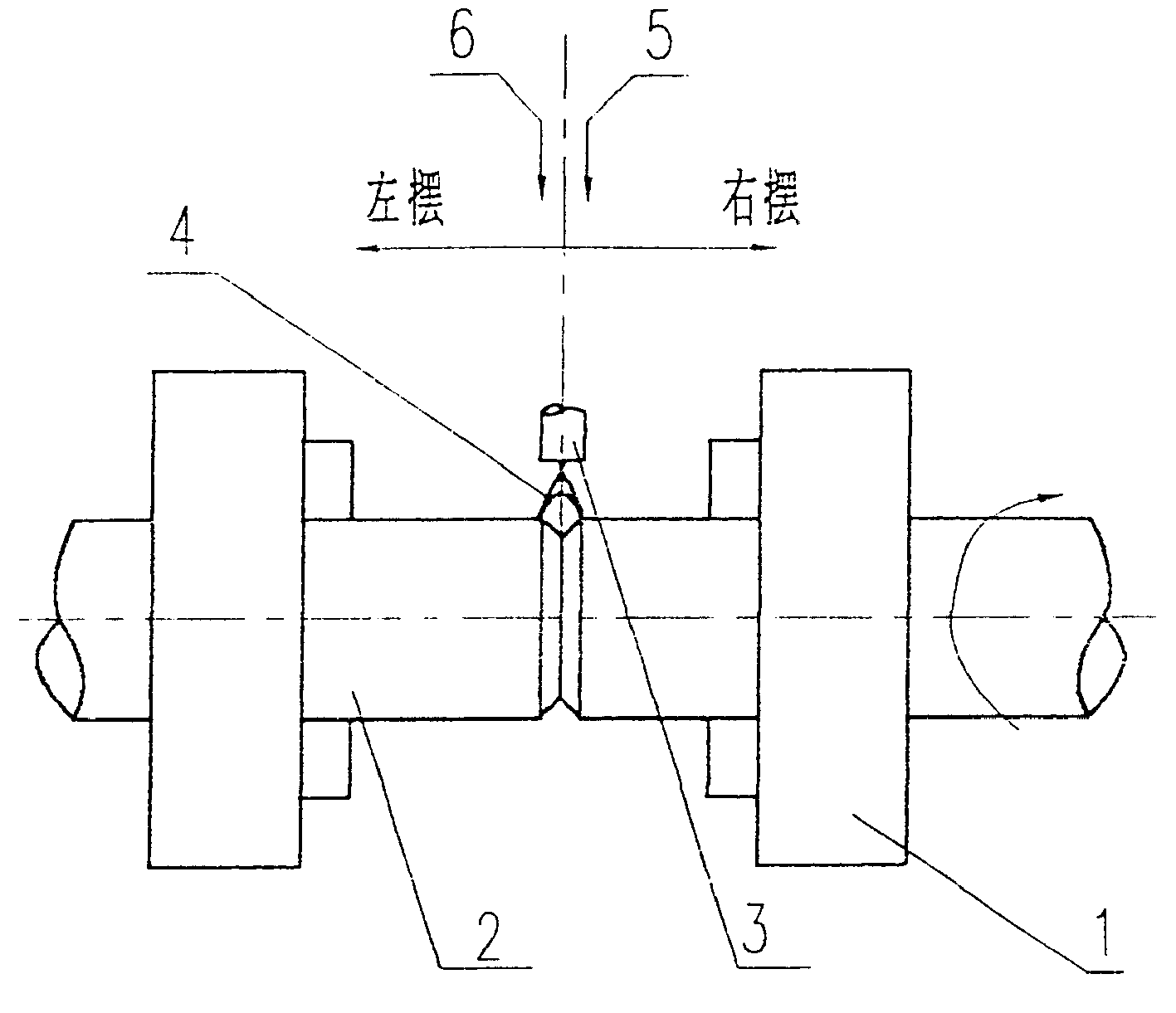

[0012] Embodiment of the present invention is provided below in conjunction with accompanying drawing, is used for further illustrating the present invention, does not mean that this invention is just limited to following:

[0013] In the picture: 1 - automatic welding machine power chuck

[0014] 2 - pipe

[0015] 3——Welding torch tungsten electrode

[0016] 4 - arc

[0017] 5——Welding power supply

[0018] 6——shielding gas

[0019] The pipe 2 is clamped and positioned on the power chuck 1 of the automatic welding machine, the start button is activated, the tungsten electrode 3 of the welding torch is quickly lowered to the top of the butt weld of the pipe 2, the shielding gas 6 is turned on, the welding power supply 5 is turned on, and the arc 4 is ignited. The power chuck 1 of the automatic welding machine starts to rotate the pipe 2, and the tungsten electrode 3 of the welding torch swings left and right. When the set heating temperature is reached, the current decays,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com