Garden road curbstone trimming device driven by using screw to precipitate dust and use method of device

A screw-driven, curbstone technology, applied in road repair, roads, roads, etc., can solve the problems of aesthetic impact, difficult to realize motorization, difficult to apply curbstone trimming, etc., to achieve reliable operation, ensure overall aesthetics, and equipment structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

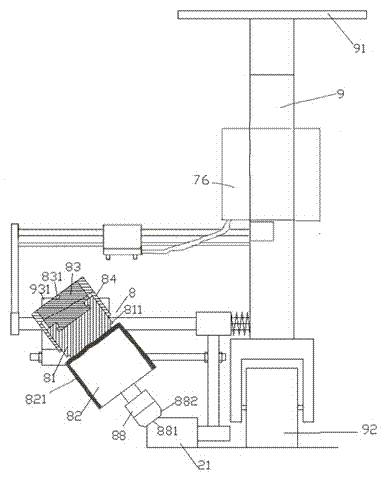

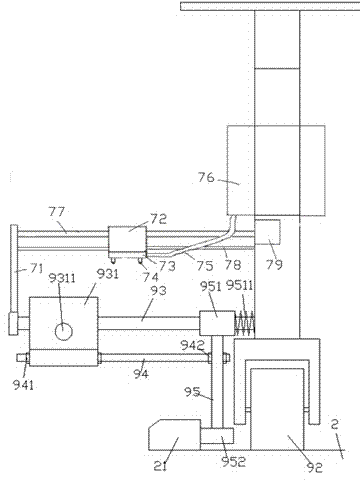

[0011] combined with Figure 1-3 , to explain the present invention in detail.

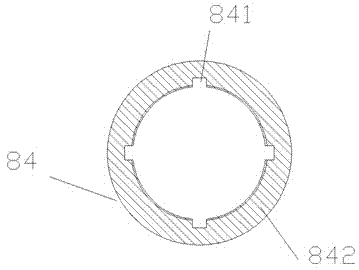

[0012] According to the example, see figure 1 , a device for trimming curb stones 21 on garden roads driven by a screw to reduce dust, for chamfering and trimming the outer top edge of the curb stones 21, including a frame 9 and a walking wheel arranged at the lower end of the frame 9 92 and the walking push handle 91 that is arranged on the upper end of the frame 9; the frame 9 is fixedly provided with a transverse bearing rod 93 above the traveling wheel 92, and the lateral bearing rod 93 slides from the inside to the outside successively to carry a guide Roller slip sleeve 951 and trimming grinding wheel assembly sliding sleeve 931 and the cross-section of described lateral load bar 93 are square to prevent described guide wheel sliding sleeve 951 and trimming grinding wheel assembly sliding sleeve 931 from rotating thereon, described guide wheel slipping The sleeve 951 is equipped with a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com