Patents

Literature

31results about How to "Effective chamfer grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulically adjusted garden road trimming device and application method thereof

ActiveCN104816215AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesGrinding wheelMechanical engineering

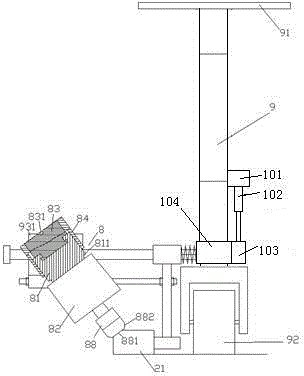

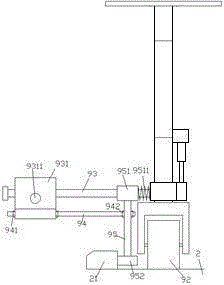

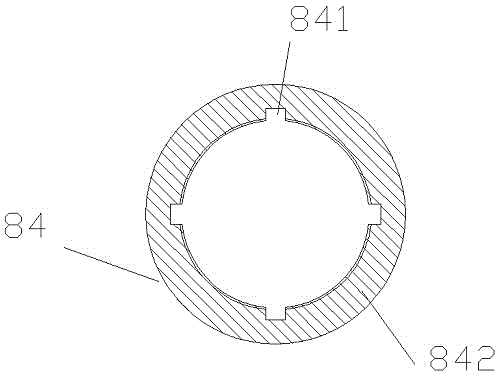

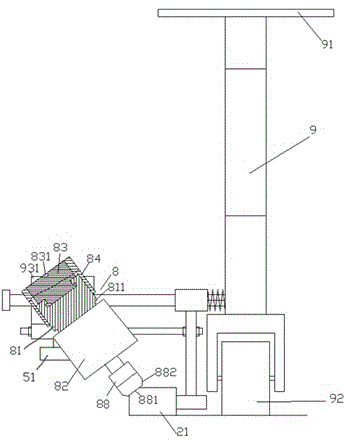

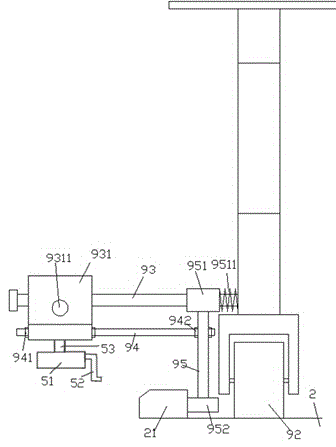

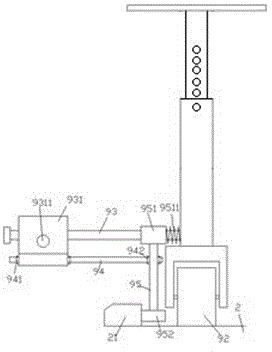

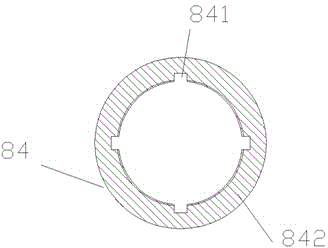

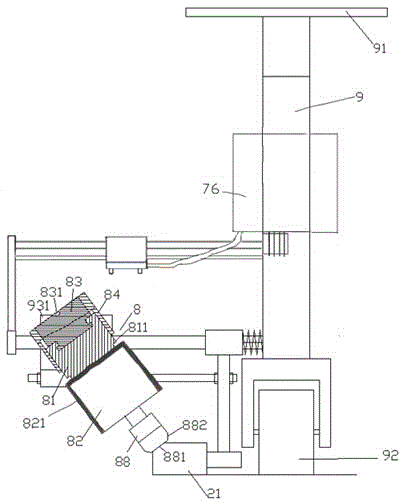

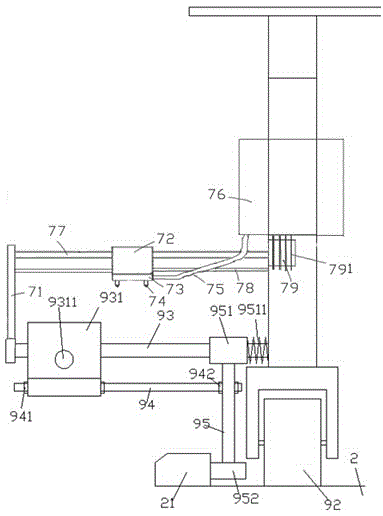

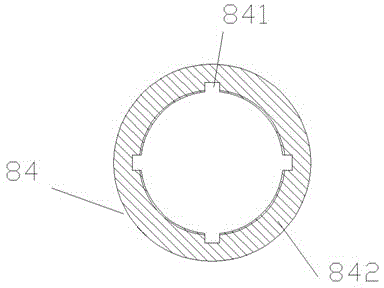

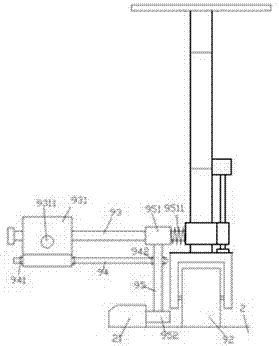

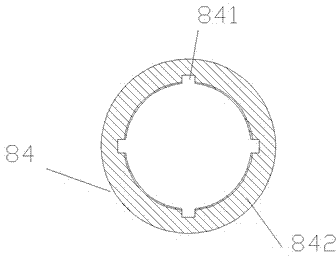

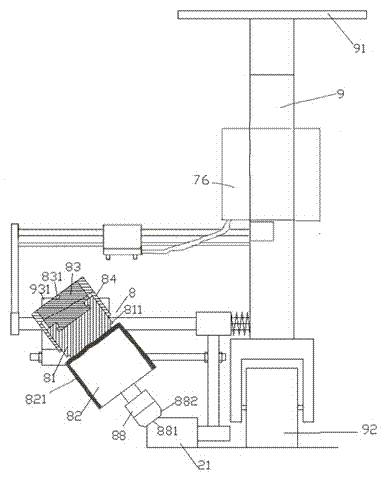

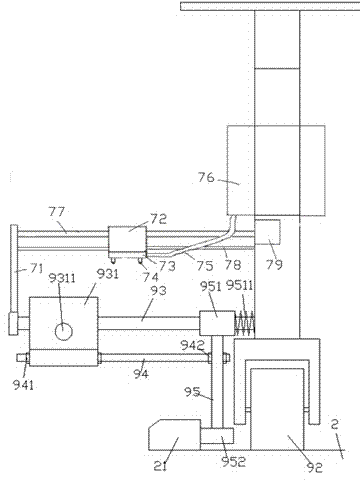

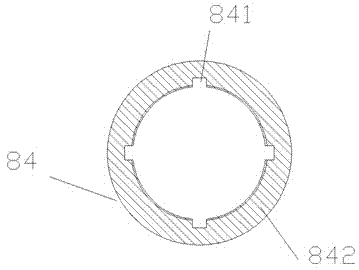

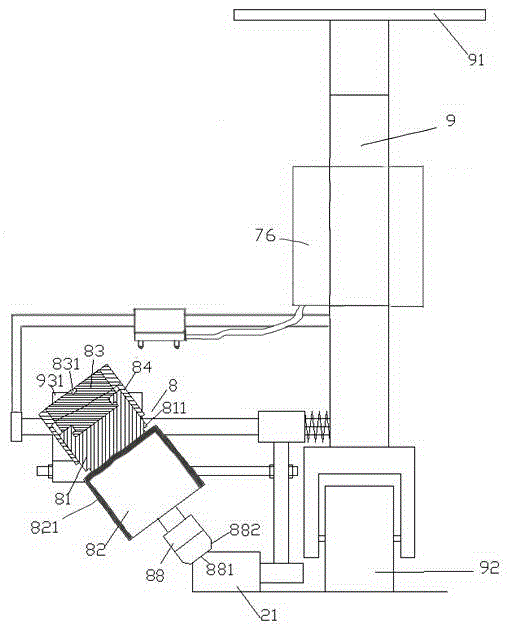

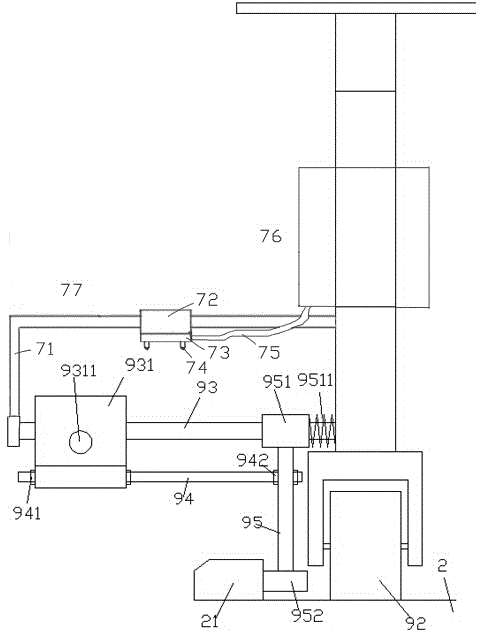

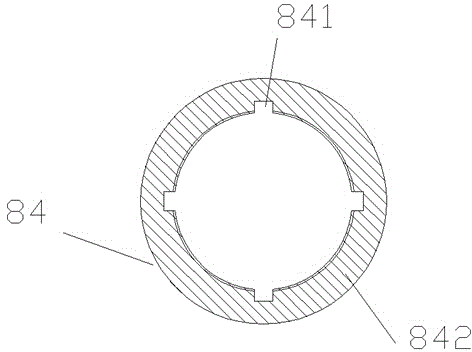

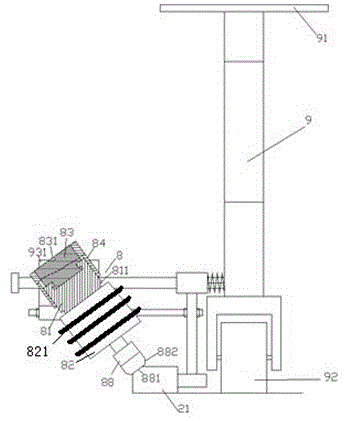

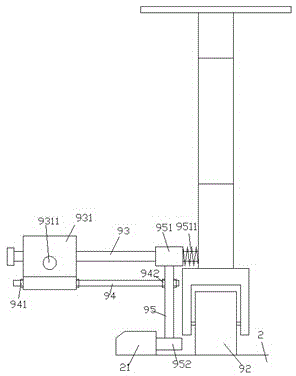

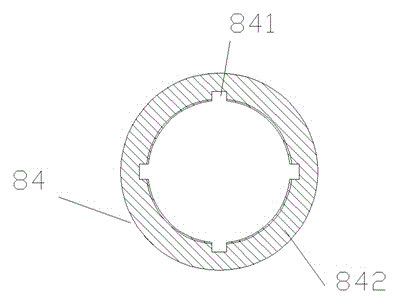

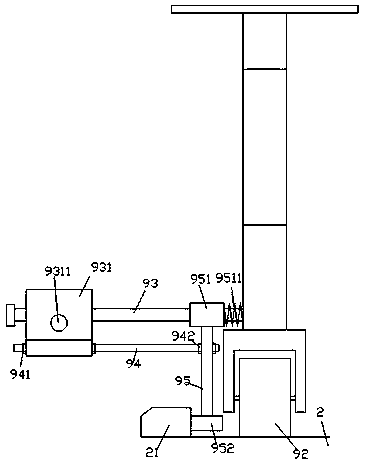

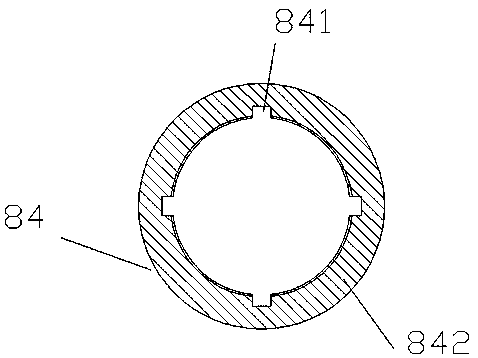

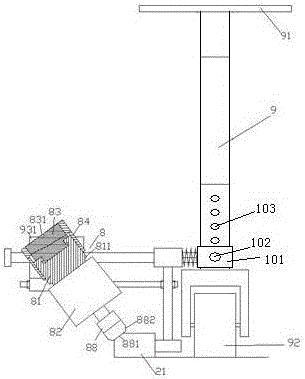

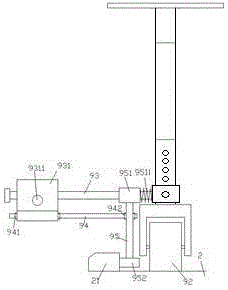

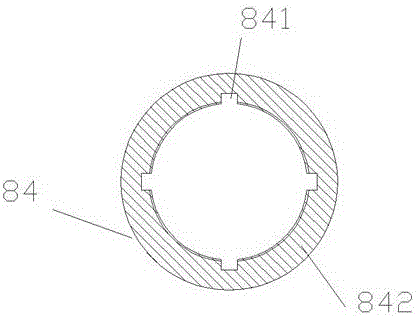

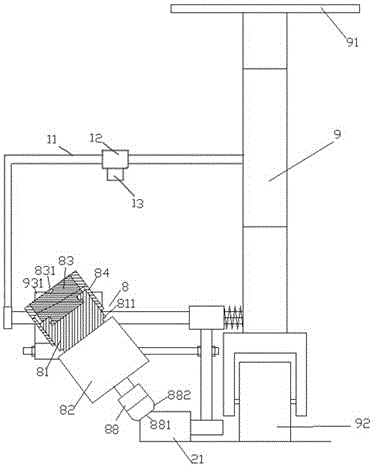

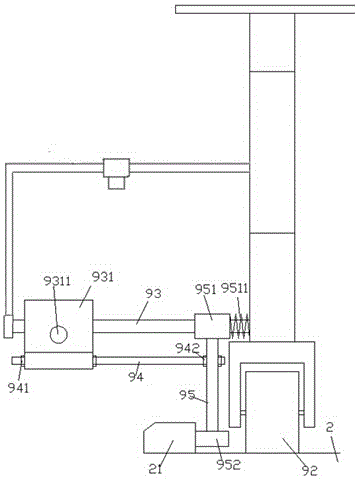

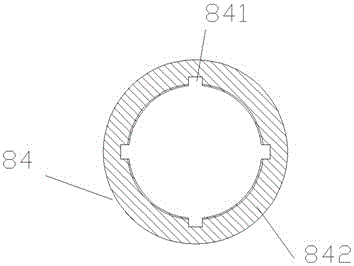

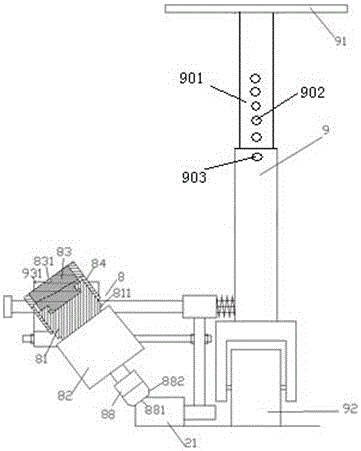

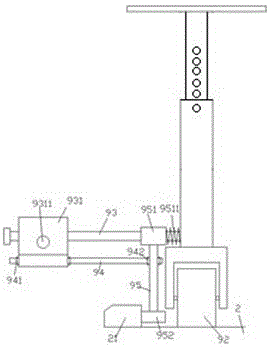

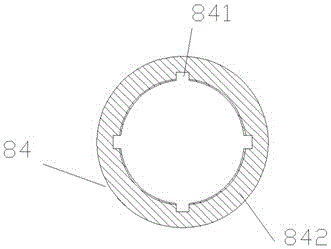

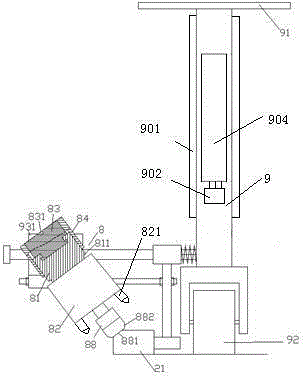

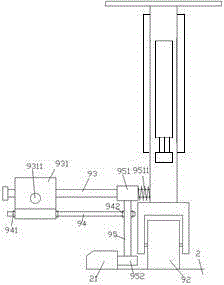

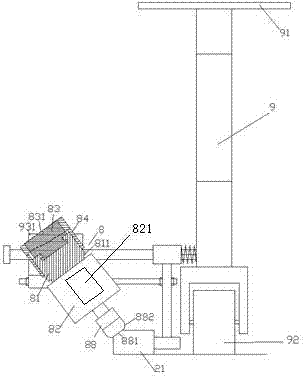

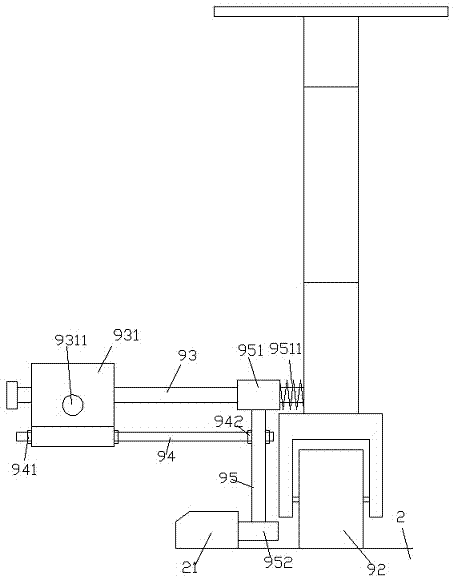

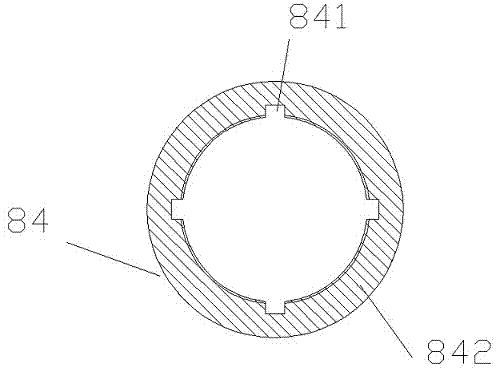

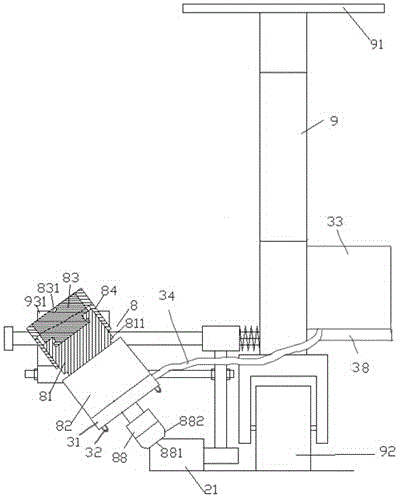

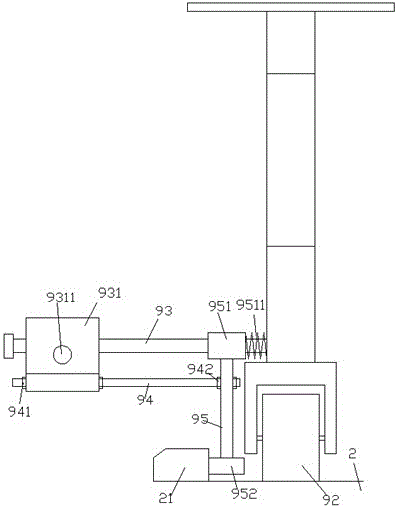

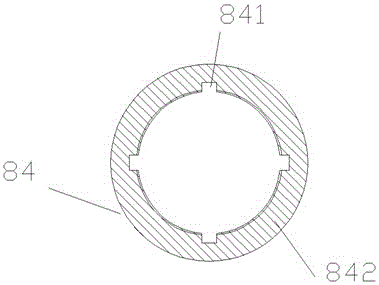

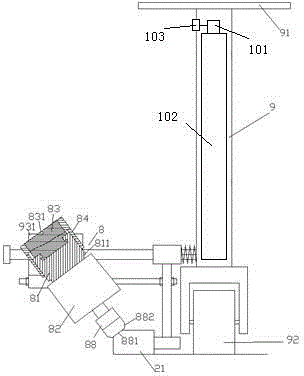

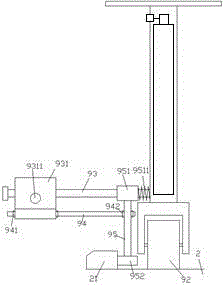

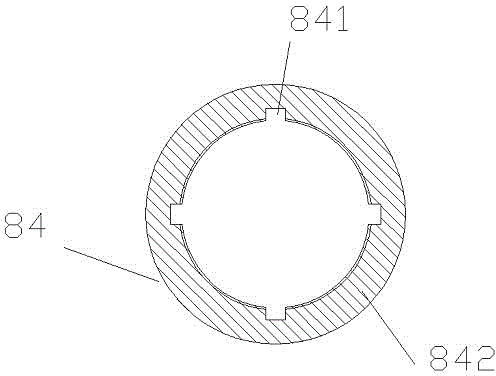

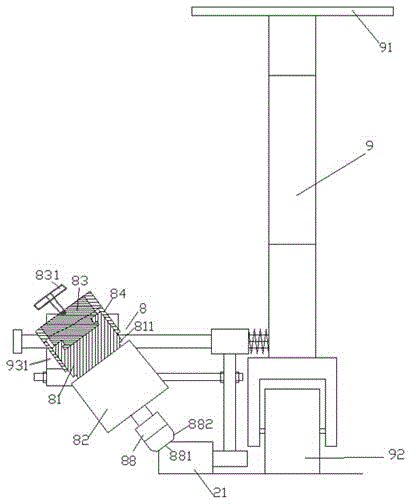

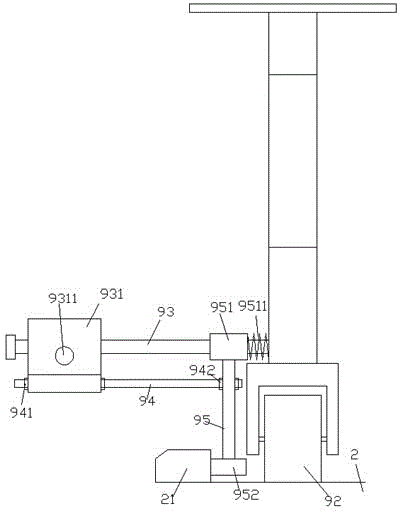

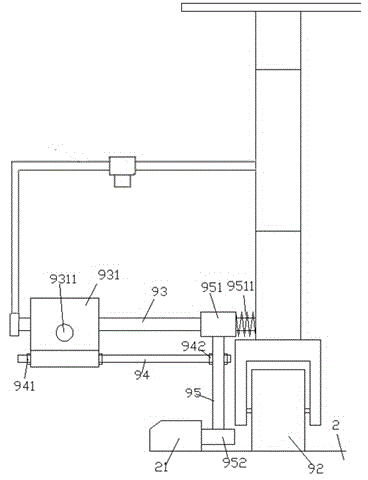

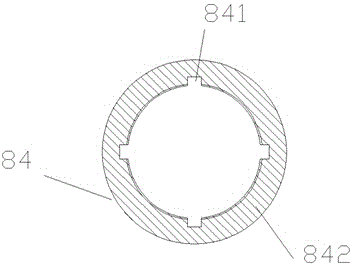

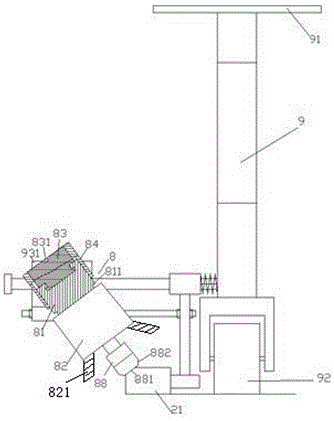

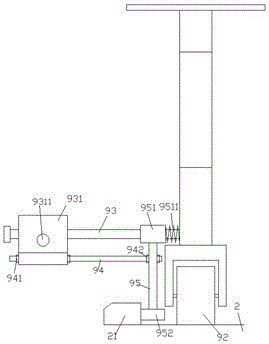

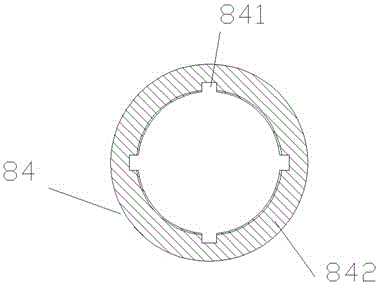

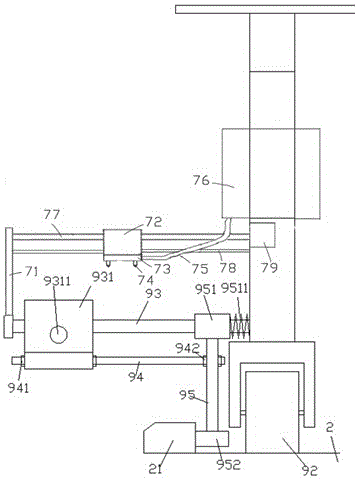

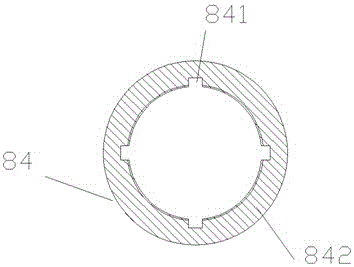

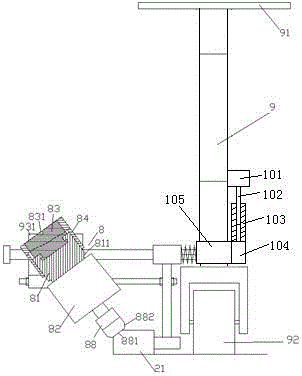

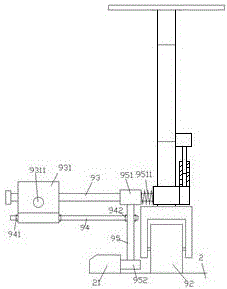

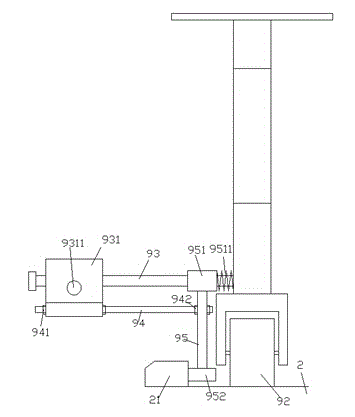

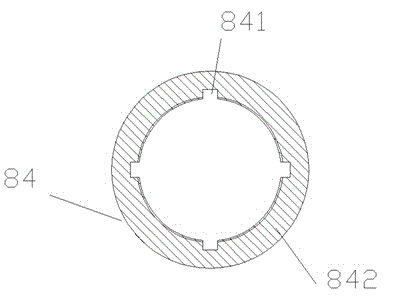

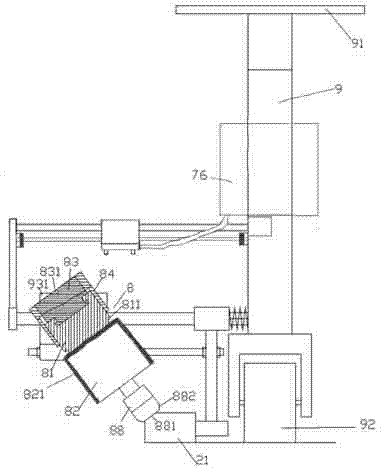

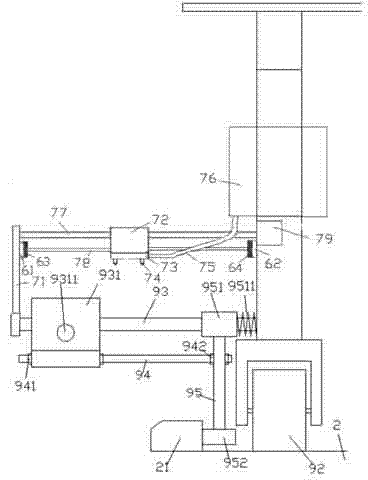

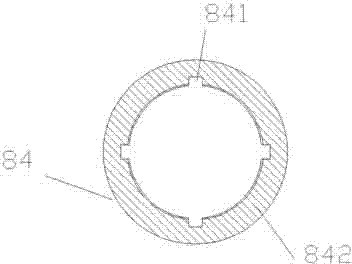

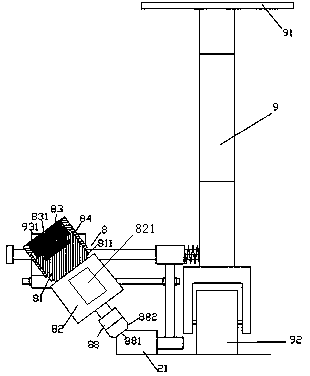

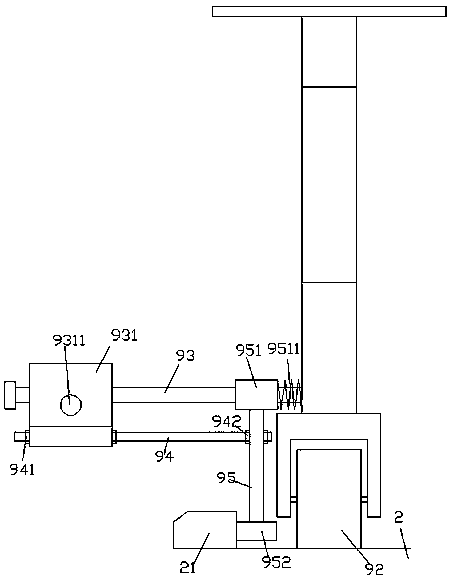

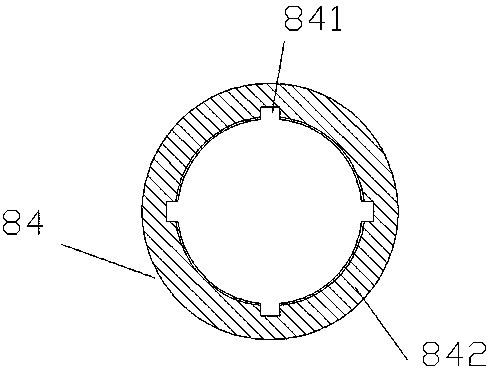

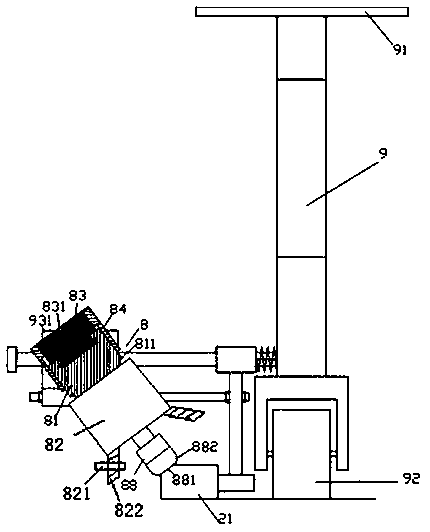

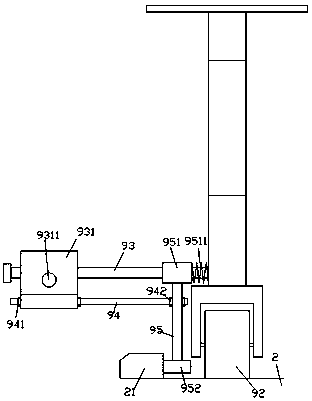

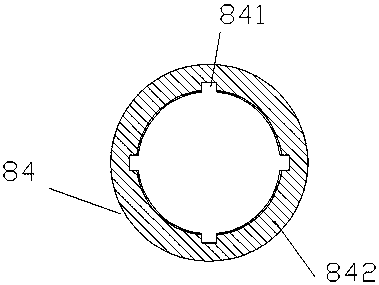

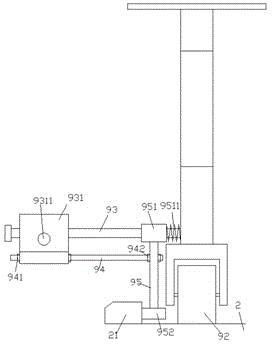

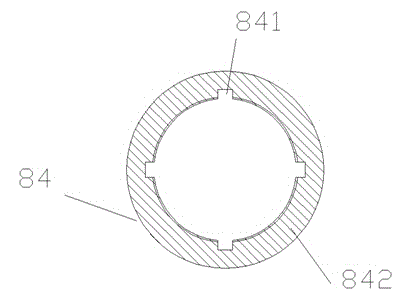

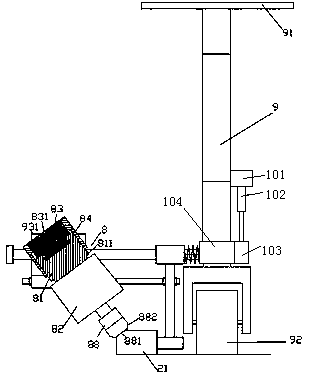

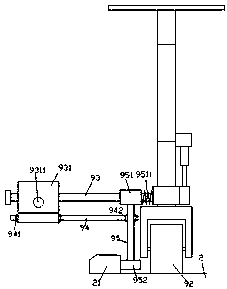

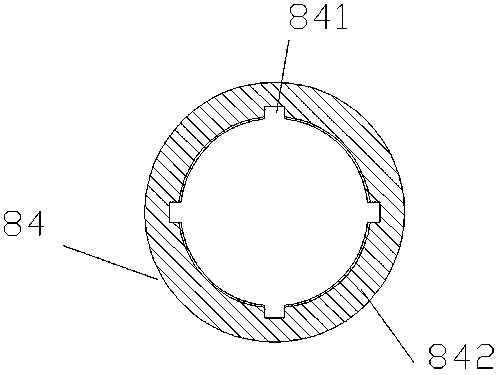

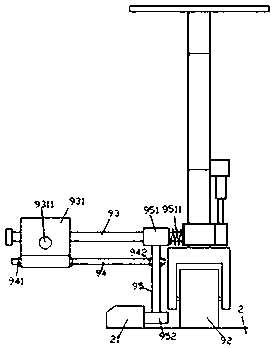

Provided are a hydraulically adjusted garden road trimming device and an application method thereof. The device is used for performing chamfering trimming on the edge of the top of the outer side of a kerb (21). The hydraulically adjusted garden road trimming device comprises a machine frame (9), walking wheels (92) at the lower end of the machine frame (9) and a walking pushing handle (91) arranged at the upper end of the machine frame (9). A sleeve part (104) matched with the machine frame (9) to slide up and down is arranged on the machine frame (9) above the walking wheels (92), and a horizontal bearing rod (93) is fixedly arranged on one side of the sleeve part (104) close to the kerb (21). A guiding wheel sliding sleeve (951) and a trimming grinding wheel module sliding sleeve (931) are sequentially slidably borne on the horizontal bearing rod (93) from inside to outside, and the cross section of the horizontal bearing rod (93) is square so as to prevent the guiding wheel sliding sleeve (951) and the trimming grinding wheel module sliding sleeve (931) from rotating on the horizontal bearing rod (93).

Owner:嘉兴笼列电子商务有限公司

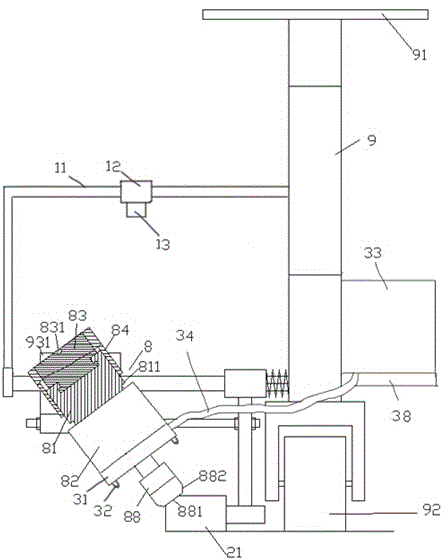

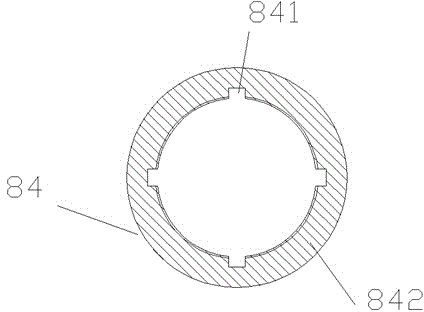

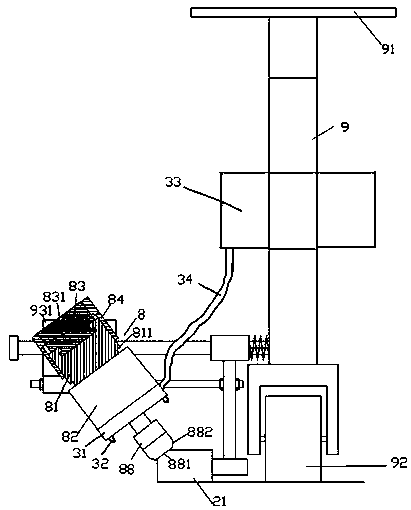

Garden road curbstone trimming device with dust collector and using method thereof

InactiveCN104816212AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringSquare Shape

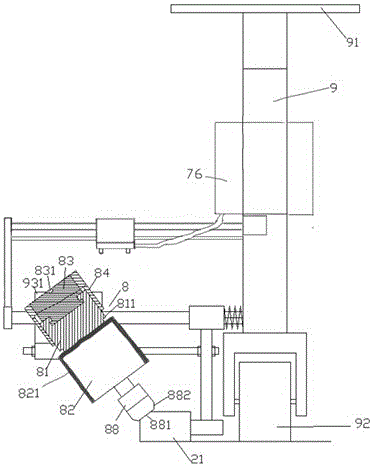

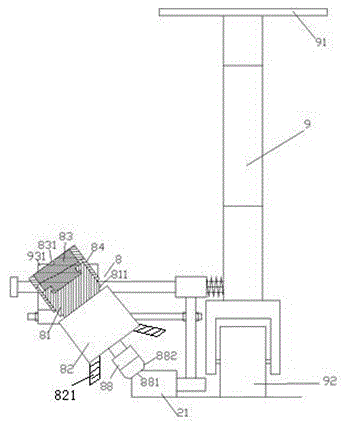

Disclosed are a garden road curbstone trimming device with a dust collector and a using method thereof. The device is used for performing chamfering and trimming on edges of top of outer side of a curbstone (21) and comprises a rack (9), walking wheels (92) and a walking push handle (91), the walking wheels (92) are arranged at the lower end of the rack (9), the walking push handle (91) is arranged at the upper end of the rack (9), a transverse bearing rod (93) is fixedly arranged above the walking wheels (92) on the rack (9), the transverse bearing rod (93) sequentially bears a guiding wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) in a sliding mode from inside to outside, and the cross section of the transverse bearing rod (93) is in a square shape so that the guiding wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) can be prevented from rotating on the transverse bearing rod (93).

Owner:邬钰盛

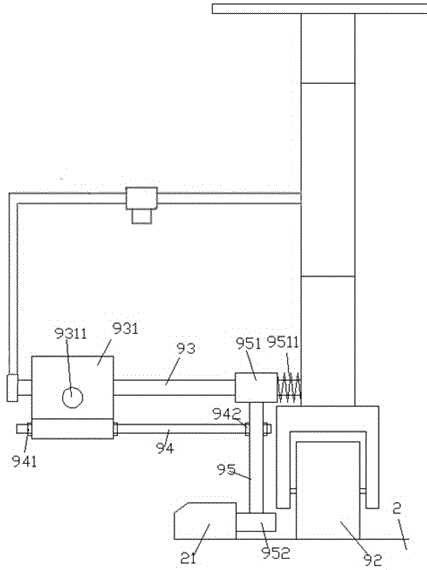

Garden road trimming device with height capable of being adjusted and using method thereof

ActiveCN104988841AGuaranteed aestheticsEffective chamfer grindingRoads maintainenceEngineeringGrinding wheel

The invention discloses a garden road trimming device with height capable of being adjusted and a using method thereof. The device is used for chamfering and trimming the edge of the top of the outer side of curbstone (21). The garden road trimming device comprises a rack (9), walking wheels (92) and a walking pushing handle (91), wherein the walking wheels (92) are arranged at the lower end of the rack (9), and the walking pushing handle (91) is arranged above the rack (9). The rack (9) is located above the walking wheels (92) and fixedly provided with a transverse bearing rod (93). The transverse bearing rod (93) bears a guiding wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) in sequence from interior to exterior, and the cross section of the transverse bearing rod (93) is square so as to prevent the guiding wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:苏州盛泽科技创业园发展有限公司

Park road curbstone trimming device provided with heat dissipating fins and using method thereof

InactiveCN104889850AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringHeat sink

The invention provides a park road curbstone trimming device provided with heat dissipating fins and a using method thereof. The device is used for chamfering and trimming the edges of the tops of the outer sides of curbstones (21). The park road curbstone trimming device comprises a rack (9), walking wheels (92) arranged at the lower end of the rack (9), and a walking pushing handle (91) arranged on the rack (9). A transverse bearing rod (93) is fixedly arranged on the portion, located above the walking wheels (92), of the rack (9). A guide wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) are sequentially carried on the transverse bearing rod (93) in a sliding mode from inside to outside. The cross section of the transverse bearing rod (93) is square to prevent the guide wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:楼天涯

Garden road trimming device for falling dust through atomizing sprayer and use method thereof

InactiveCN104889851AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesUsing liquid separation agentSprayerEngineering

The invention discloses a garden road trimming device for falling dust through an atomizing sprayer and a use method thereof. The device is used for carrying out chamfering trimming on the top edge of the outer side of a road curbstone on a garden road and comprises a machine frame (9), a walking wheel (92) arranged at the lower end of the machine frame (9) and a walking pushing handle (91) arranged at the upper end of the machine frame (9), wherein a transverse bearing rod (93) is fixedly arranged at the position, above the walking wheel (92), of the machine frame (9); a guide wheel sliding sleeve (951) and a trimming and grinding wheel assembly sliding sleeve (931) are sequentially arranged on the transverse bearing rod (93) in a sliding mode from inside to outside; the cross section of the transverse bearing rod (93) is square to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:方星

Screw adjustment garden road trimming device and using method thereof

InactiveCN104846723AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceEngineeringGrinding wheel

The invention relates to a screw adjustment garden road trimming device and a using method thereof. The device is used for carrying out chamfer trimming on the edge of the top outside a curbstone (21) and comprises a rack (9), a traveling wheel (92) arranged at the lower end of the rack (9) and a traveling push handle (91) arranged at the upper end of the rack (9); a sleeve part (105) matched with the rack (9) to slide up and down is arranged on the rack (9) and above the traveling wheel (92); a transverse bearing rod (93) is fixedly arranged at one side, which is close to the curbstone (21), of the sleeve part (105); a guide wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) are sequentially borne in a sliding manner on the transverse bearing rod (93) from inside to outside and the cross section of the transverse bearing rod (93) is of a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:方星

Garden road curbstone trimming device driven by using screw to precipitate dust and use method of device

InactiveCN104846722ASimple equipment structureReliable operationEdge grinding machinesRoads maintainenceSquare ShapeMechanical engineering

The invention provides a garden road curbstone (21) trimming device driven by using a screw to precipitate dust and a use method of the device. The device is used for performing chamfering and trimming on the top edge of the outer side of the curbstone (21) and comprises a stand (9), a walking wheel (92) and a walking pushing handle (91), wherein the walking wheel (92) is arranged at the lower end of the stand (9), and the walking pushing handle (91) is arranged at the upper end of the stand (9); the stand (9) is positioned above the walking wheel (92) and is fixed with a cross loading rod (93), the cross loading rod (93) loads a guide wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) from interior to exterior in sequence, and the cross section of the cross loading rod (93) is in a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) to rotate on the cross loading rod (93).

Owner:ZHEJIANG BUSINESS TECH INST

Trimming device for curbstone on garden road and capable of reducing dust and using method of trimming device

InactiveCN104924174AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesMechanical engineering

The invention discloses a trimming device for curbstone on a garden road and capable of reducing dust and a using method of the trimming device. The trimming device is used for carrying out chamfer trimming on the edge of the top of the outer side of the curbstone (21) and comprises a rack (9), a walking wheel (92) arranged at the lower end of the rack (9) and a walking pushing handle (91) arranged at the upper end of the rack (9). The rack (9) is located above the walking wheel (92) and is fixedly provided with a transverse bearing rod (93), and a guide wheel sliding sleeve (951) and a trimming polishing wheel component sliding sleeve (931) are sequentially borne on the transverse bearing rod (93) in a sliding manner from inside to outside; and the cross section of the transverse bearing rod (93) is square, and therefore the transverse bearing rod (93) prevents the guide wheel sliding sleeve (951) and the trimming polishing wheel component sliding sleeve (931) from rotating on the rod.

Owner:ZHEJIANG BUSINESS TECH INST

Garden road trimming device capable of radiating quickly and using method thereof

InactiveCN104963268APrevent rotationExtended service lifeRoads maintainenceGrinding wheelMechanical engineering

The invention relates to a garden road trimming device capable of radiating quickly and a using method of the garden road trimming device. The device is used for chamfering and trimming the edge of the top on the outer side of a curbstone (21). The device comprises a frame (9), a walking wheel (92) arranged at the lower end of the frame (9), and a walking pushing handle (91) arranged at the upper end of the frame (9). The part, positioned above the walking wheel (92), of the frame (9) is fixedly provided with a transverse bearing rod (93), a guide wheel sliding sleeve (951) and a trimming grinding wheel sliding sleeve (931) are slidingly borne on the transverse bearing rod (93) in sequence from inside to outside, and the cross section of the transverse bearing rod (93) is square to prevent the guide wheel sliding sleeve (951) and the trimming grinding wheel sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:邬时伟

Curb stone used for garden roads and dust-reducing edge trimming device and using method thereof

ActiveCN104802056BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringGrinding wheel

The invention discloses a trimming device used for road traffic stones of a garden road and capable of reducing dust and a using method for the trimming device. The device is used for performing chamfered trimming on the top side edges at the outer sides of the road traffic stones (21), and comprises a rack (9), a travelling wheel (92) arranged at the lower end of the rack (9) and a travelling pushing handle (91) which is arranged at the upper end of the rack (9), wherein the rack (9) is positioned above the travelling wheel (92) and fixedly provided with a transverse bearing rod (93); a guide wheel slide sleeve (951) and a trimming and grinding wheel component slide sleeve (931) are borne on the transverse bearing rod (9) from inside to outside in sequence in a sliding mode; the cross section of the transverse bearing rod (93) is square to prevent the guide wheel slide sleeve (951) and the trimming and grinding wheel component slide sleeve (931) from rotating on the transverse bearing rod (93).

Owner:岭南设计集团有限公司

Edge trimming device for garden road with adjustable processing height and method of using the same

ActiveCN104846721BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesEngineeringGrinding wheel

Owner:杭州市交通工程集团有限公司

Device for trimming curbs on garden roads with lighting lamps and method of use thereof

ActiveCN104929021BGuaranteed aestheticsEffective chamfer grindingPlane surface grinding machinesEngineeringMechanical engineering

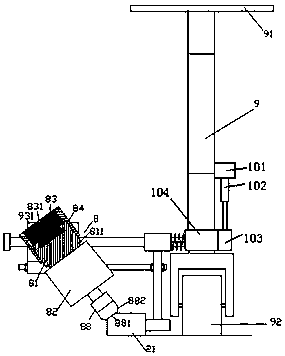

The invention discloses a trimming device provided with a lighting lamp, for a curbstone (21) on a garden path, and a using method of the trimming device. The trimming device is used for chamfering the top edge on the outer side of the curbstone (21). The trimming device comprises a frame (9), a traveling wheel (92) arranged at the lower end of the frame (9), and a traveling driving handle (91) arranged at the upper end of the frame (9); a transverse bearing rod (93) is fixedly arranged on the frame (9), above the traveling wheel (92); a guide wheel sliding sleeve (951) and a trimming and polishing wheel assembly sliding sleeve (931) are born on the transverse bearing rod (93) in a sliding manner from inside to outside, and the cross section of the transverse bearing rod (93) is square, so that the guide wheel sliding sleeve (951) and the trimming and polishing wheel assembly sliding sleeve (931) can be prevented from rotating on the transverse bearing rod (93).

Owner:贵阳渝冠技术服务中心

Height-adjustable garden road edge trimming device and using method thereof

ActiveCN104988841BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding wheelMechanical engineering

The invention discloses a garden road trimming device with height capable of being adjusted and a using method thereof. The device is used for chamfering and trimming the edge of the top of the outer side of curbstone (21). The garden road trimming device comprises a rack (9), walking wheels (92) and a walking pushing handle (91), wherein the walking wheels (92) are arranged at the lower end of the rack (9), and the walking pushing handle (91) is arranged above the rack (9). The rack (9) is located above the walking wheels (92) and fixedly provided with a transverse bearing rod (93). The transverse bearing rod (93) bears a guiding wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) in sequence from interior to exterior, and the cross section of the transverse bearing rod (93) is square so as to prevent the guiding wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:苏州盛泽科技创业园发展有限公司

Solar energy powered and illuminated park road trimming device and using method thereof

ActiveCN104831608AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceEngineeringGrinding wheel

The invention discloses a solar energy powered and illuminated park road trimming device and a using method thereof. The device is used for chamfering and trimming the top edge of the outer side of a curb stone (21) and comprises a rack (9), walking wheels (92) arranged at the lower end of the rack (9), and a walk pushing hand (91) arranged at the upper end of the rack (90); a transverse bearing rod (92) is fixedly arranged on the rack (9), above the walking wheels (92); a guide wheel sliding sleeve (951) and a trimming and grinding wheel component sliding sleeve (931) are borne on the transverse bearing rod (93) from inside to outside in sequence; the cross section of the transverse bearing rod (93) is rectangular, so as to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel component sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:泰安智慧谷产业园运营管理有限公司

Speed adjustable garden road trimming device and using method thereof

ActiveCN104846725AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceEngineeringGrinding wheel

The invention relates to a speed adjustable garden road trimming device and a using method thereof. The device is used for carrying out chamfer trimming on the edge of the top outside a curbstone (21) and comprises a rack (9), a traveling wheel (92) arranged at the lower end of the rack (9) and a traveling push handle (91) arranged at the upper end of the rack (9); a transverse bearing rod (93) is fixedly arranged on the rack (9) and above the traveling wheel (92); a guide wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) are sequentially borne in a sliding manner on the transverse bearing rod (93) from inside to outside and the cross section of the transverse bearing rod (93) is of a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:ZAOZHUANG HAIDI ENERGY TECH

Stable operation and dust-absorbing edge trimming device for curbstone on garden roads and its application method

InactiveCN104831606BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesEngineeringGrinding wheel

The invention discloses a stably operated park road curb stone (21) trimming device capable of collecting dust and a using method thereof. The device is used for chamfering and trimming the top edge of the outer side of a curb stone (21) and comprises a rack (9), walking wheels (92) arranged at the lower end of the rack (9), and a walk pushing hand (91) arranged at the upper end of the rack (90); a transverse bearing rod (92) is fixedly arranged on the rack (9), above the walking wheels (92); a guide wheel sliding sleeve (951) and a trimming and grinding wheel component sliding sleeve (931) are borne on the transverse bearing rod (93) from inside to outside in sequence; the cross section of the transverse bearing rod (93) is rectangular, so as to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel component sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:石家庄金世鹏环境艺术有限公司

Portable park road trimming device and using method thereof

InactiveCN104831609AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceGrinding wheelMechanical engineering

The invention discloses a portable park road trimming device and a using method thereof. The device is used for chamfering and trimming the top edge of the outer side of a curb stone (21) and comprises a rack (9), walking wheels (92) arranged at the lower end of the rack (9), and a walk pushing hand (91) arranged at the upper end of the rack (90); a transverse bearing rod (92) is fixedly arranged on the rack (9), above the walking wheels (92); a guide wheel sliding sleeve (951) and a trimming and grinding wheel component sliding sleeve (931) are borne on the transverse bearing rod (93) from inside to outside in sequence; the cross section of the transverse bearing rod (93) is rectangular, so as to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel component sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:桐乡市濮院舍尔得针织制衣厂

Conveniently operated park road curb stone trimming device and using method thereof

InactiveCN104831607AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceGrinding wheelMechanical engineering

The invention discloses a conveniently operated park road curb stone trimming device and a using method thereof. The device is used for chamfering and trimming the top edge of the outer side of a curb stone (21) and comprises a rack (9), walking wheels (92) arranged at the lower end of the rack (9), and a walk pushing hand (91) arranged at the upper end of the rack (90); a transverse bearing rod (92) is fixedly arranged on the rack (9), above the walking wheels (92); a guide wheel sliding sleeve (951) and a trimming and grinding wheel component sliding sleeve (931) are borne on the transverse bearing rod (93) from inside to outside in sequence; the cross section of the transverse bearing rod (93) is rectangular, so as to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel component sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:邬钰盛

Trimming device provided with lighting lamp, for curbstone on garden path, and using method of trimming device

ActiveCN104929021AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceMechanical engineering

The invention discloses a trimming device provided with a lighting lamp, for a curbstone (21) on a garden path, and a using method of the trimming device. The trimming device is used for chamfering the top edge on the outer side of the curbstone (21). The trimming device comprises a frame (9), a traveling wheel (92) arranged at the lower end of the frame (9), and a traveling driving handle (91) arranged at the upper end of the frame (9); a transverse bearing rod (93) is fixedly arranged on the frame (9), above the traveling wheel (92); a guide wheel sliding sleeve (951) and a trimming and polishing wheel assembly sliding sleeve (931) are born on the transverse bearing rod (93) in a sliding manner from inside to outside, and the cross section of the transverse bearing rod (93) is square, so that the guide wheel sliding sleeve (951) and the trimming and polishing wheel assembly sliding sleeve (931) can be prevented from rotating on the transverse bearing rod (93).

Owner:贵阳渝冠技术服务中心

Garden road edge trimming device with dust cover and using method thereof

ActiveCN104947572BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesDirt cleaningMechanical engineeringRoad traffic

Owner:湖南省金凯建设集团有限公司

Edge trimming device for tarmac on garden road using screw drive to reduce dust and using method

InactiveCN104846722BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceRoad dustMechanical engineering

A device for trimming curb stones (21) on garden roads driven by a screw to reduce dust and its use method, the device is used for chamfering and trimming the outer top edge of the curb stone (21), including a frame ( 9), the walking wheels (92) set at the lower end of the frame (9) and the walking push handle (91) set at the upper end of the frame (9); the frame (9) is located above the walking wheels (92) A transverse bearing rod (93) is fixedly installed, and the guide wheel sliding sleeve (951) and the trimming and grinding wheel assembly sliding sleeve (931) are slid on the lateral bearing rod (93) in sequence from the inside to the outside. (93) has a square cross section to prevent the guide wheel sliding sleeve (951) and the trimming and grinding wheel assembly sliding sleeve (931) from rotating thereon.

Owner:ZHEJIANG BUSINESS TECH INST

Sleeve-adjustable garden road trimming device and method of use thereof

ActiveCN104846720BGuaranteed aestheticsEffective chamfer grindingRoads maintainenceEngineeringMechanical engineering

The invention provides a sleeve-adjusted garden road trimming device and a use method thereof. The device is used for performing chamfering and trimming on the top edge of the outer side of a curbstone (21) and comprises a stand (9), a walking wheel (92) and a walking pushing handle (91), wherein the walking wheel (92) is arranged at the lower end of the stand (9), and the walking pushing handle (91) is arranged at the upper end of the stand (9); a sleeving component (105) is arranged on the stand (9), which is positioned above the walking wheel (92), and slides up and down by matching the stand (9); one side, close to the curbstone (21), of the sleeving component (105) is fixed with a cross loading rod (93), the cross loading rod (93) loads a guide wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) from interior to exterior in sequence in a sliding manner, and the cross section of the cross loading rod (93) is in a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) to rotate on the cross loading rod (93).

Owner:倡创(上海)咨询管理事务所

Garden road trimming device with water spraying function and using method thereof

InactiveCN104816214AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringWater spray

Disclosed are a garden road trimming device with a water spraying function and a using method thereof. The device is used for performing chamfering and trimming on edges of top of outer side of a curbstone (21) and comprises a rack (9), walking wheels (92) and a walking push handle (91), the walking wheels (92) are arranged at the lower end of the rack (9), the walking push handle (91) is arranged at the upper end of the rack (9), a transverse bearing rod (93) is fixedly arranged above the walking wheels (92) on the rack (9), the transverse bearing rod (93) sequentially bears a guiding wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) in a sliding mode from inside to outside, and the cross section of the transverse bearing rod (93) is in a square shape so that the guiding wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) can be prevented from rotating on the transverse bearing rod (93).

Owner:四川蓝光金谷环境科技有限公司

Garden road curbstone trimming device using limit sensor and use method of device

InactiveCN104846719AGuaranteed aestheticsEffective chamfer grindingRoads maintainenceEngineeringMechanical engineering

The invention provides a garden road curbstone (21) trimming device using a limit sensor and a use method of the device. The device is used for performing chamfering and trimming on the top edge of the outer side of the curbstone (21) and comprises a stand (9), a walking wheel (92) and a walking pushing handle (91), wherein the walking wheel (92) is arranged at the lower end of the stand (9), and the walking pushing handle (91) is arranged at the upper end of the stand (9); the stand (9) is positioned above the walking wheel (92) and is fixed with a cross loading rod (93), the cross loading rod (93) loads a guide wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) from interior to exterior in sequence, and the cross section of the cross loading rod (93) is in a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) to rotate on the cross loading rod (93).

Owner:ZHEJIANG BUSINESS TECH INST

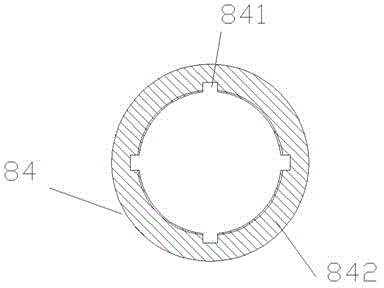

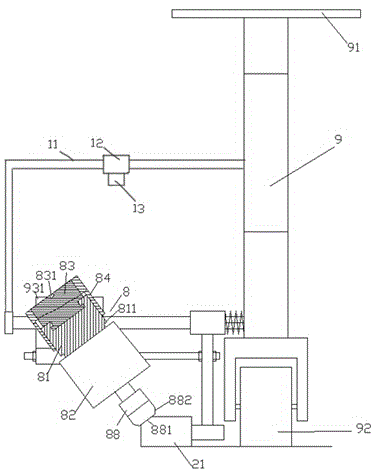

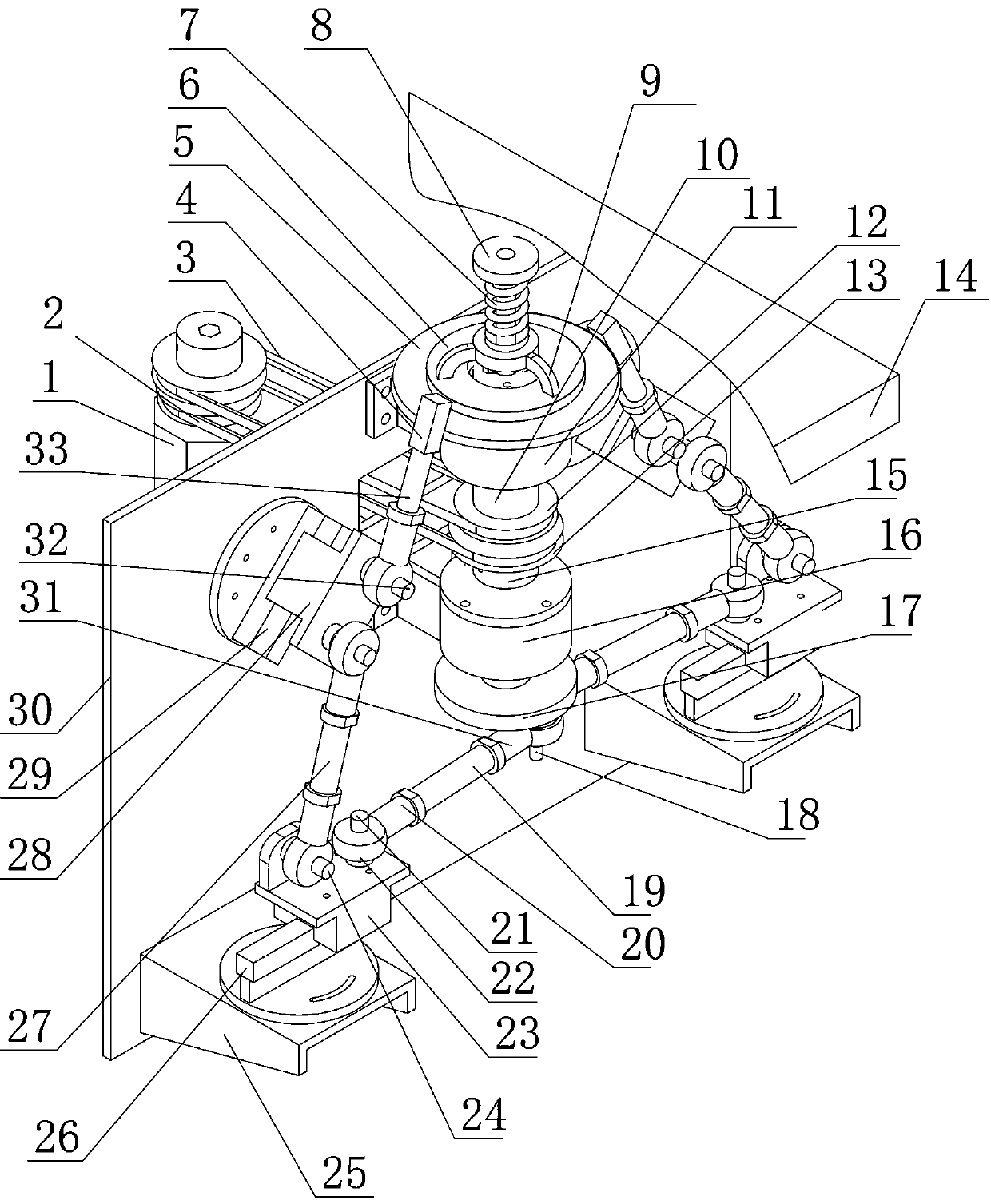

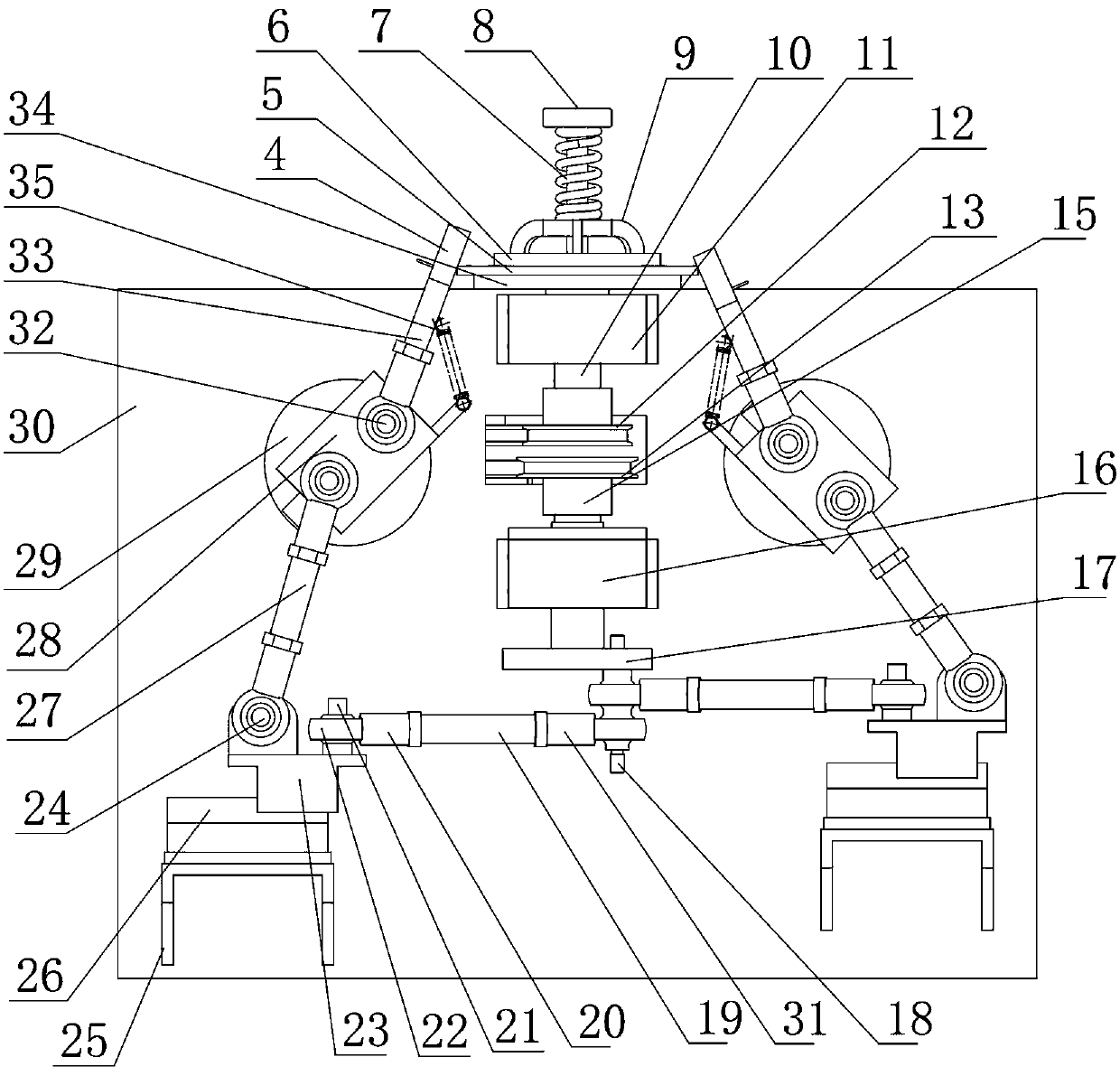

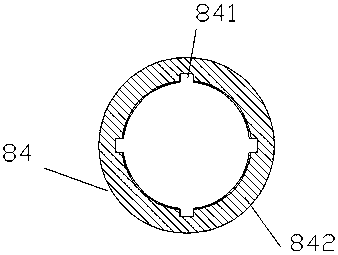

Chamfering and grinding device for disc-cutting edge

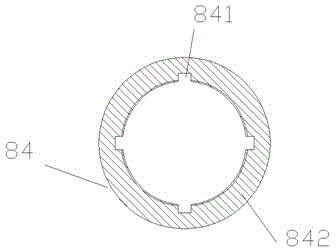

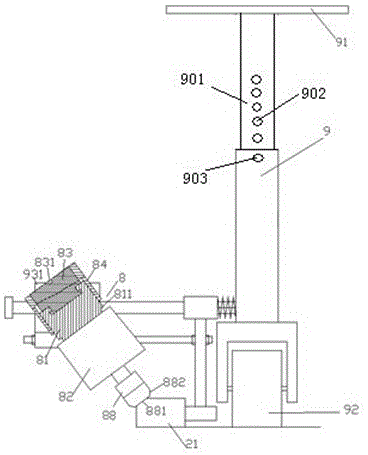

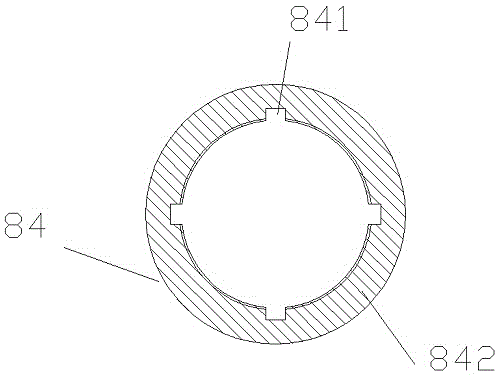

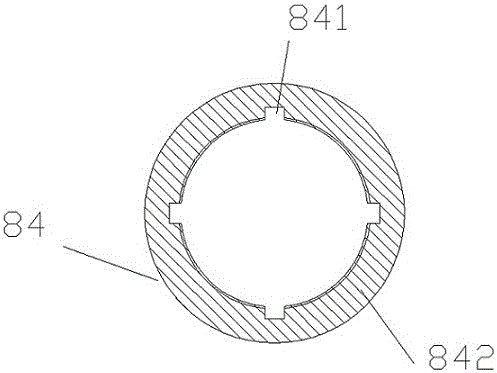

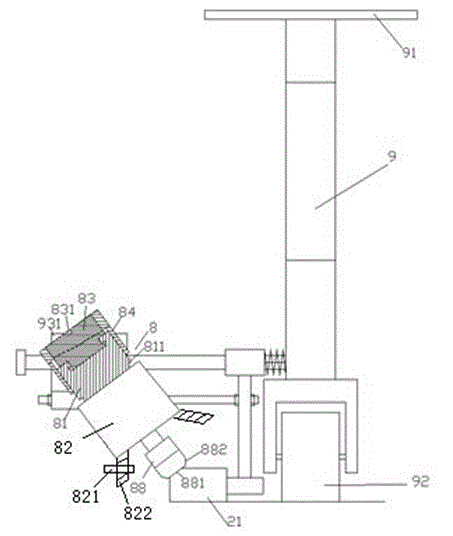

ActiveCN107553228ASimple designEasy assembly and debuggingGrinding drivesOther manufacturing equipments/toolsCircular discLinear motion

The invention belongs to the technical field of cold-rolled strip manufacturing tool, and particularly relates to a chamfering and grinding device for a disc-cutting edge. The chamfering and grindingdevice comprises a support platform, a support vertical plate, a driving device, a cutting edge piece rotation motion transmission device and a grinding head reciprocating linear motion transmission device, wherein the cutting edge piece rotation motion transmission device comprises an upper transmission wheel, an upper transmission shaft, a cutting edge tray, a cutting edge piece, a pressure cover component and an upper bearing component; the grinding head reciprocating linear motion transmission device comprises a lower transmission wheel, a lower transmission shaft, a sliding block rotatingdisc, an eccentric shaft, a connecting rod transmission mechanism I, a connecting rod transmission mechanism II and a lower bearing component; and each of the connecting rod transmission mechanism Iand the connecting rod transmission mechanism II is connected with the cutting edge piece. According to the chamfering and grinding device for the disc-cutting edge, the two types of motion, namely the rotation motion and the linear motion are realized by adopting the same driving device, all the components adopt an adjustable assembling method, the design and the structure are simple, the assembly and debugging are simple and easy, the requirement on the manufacturing precision is not too high, the processing difficulty and cost of the equipment are reduced, and the utilization ratio and production efficiency of the equipment are improved.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

Adjustable speed garden road edge trimming device and using method thereof

ActiveCN104846725BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceGrinding wheelMechanical engineering

The invention relates to a speed adjustable garden road trimming device and a using method thereof. The device is used for carrying out chamfer trimming on the edge of the top outside a curbstone (21) and comprises a rack (9), a traveling wheel (92) arranged at the lower end of the rack (9) and a traveling push handle (91) arranged at the upper end of the rack (9); a transverse bearing rod (93) is fixedly arranged on the rack (9) and above the traveling wheel (92); a guide wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) are sequentially borne in a sliding manner on the transverse bearing rod (93) from inside to outside and the cross section of the transverse bearing rod (93) is of a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:ZAOZHUANG HAIDI ENERGY TECH

Garden road edge trimming device with water spray function and its use method

InactiveCN104816214BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringWater spray

Disclosed are a garden road trimming device with a water spraying function and a using method thereof. The device is used for performing chamfering and trimming on edges of top of outer side of a curbstone (21) and comprises a rack (9), walking wheels (92) and a walking push handle (91), the walking wheels (92) are arranged at the lower end of the rack (9), the walking push handle (91) is arranged at the upper end of the rack (9), a transverse bearing rod (93) is fixedly arranged above the walking wheels (92) on the rack (9), the transverse bearing rod (93) sequentially bears a guiding wheel sliding sleeve (951) and a trimming polishing wheel assembly sliding sleeve (931) in a sliding mode from inside to outside, and the cross section of the transverse bearing rod (93) is in a square shape so that the guiding wheel sliding sleeve (951) and the trimming polishing wheel assembly sliding sleeve (931) can be prevented from rotating on the transverse bearing rod (93).

Owner:四川蓝光金谷环境科技有限公司

Garden road trimming device with dustproof cover and application method thereof

ActiveCN104947572AGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesDirt cleaningEngineeringRoad traffic

The invention provides a garden road trimming device with a dustproof cover and an application method thereof. The device is used for carrying out chamfering and trimming on the top edge of the outer side of a road traffic stone (21), and comprises a rack (9), a walking wheel (92) arranged at the lower end of the rack (9) and a walking pushing handle (91) arranged at the upper end of the rack (9), wherein the rack (9) is fixedly provided with a transverse bearing rod (93) above the walking wheel (92); the transverse bearing rod (93) is sequentially provided with a guide wheel slide sleeve (951) and a trimming polishing wheel assembly slide sleeve (931) from inside to outside in a sliding bearing manner; and the cross section of the transverse bearing rod (93) is square so as to prevent the guide wheel slide sleeve (951) and the trimming polishing wheel assembly slide sleeve (931) from rotating on the transverse bearing rod (93).

Owner:湖南省金凯建设集团有限公司

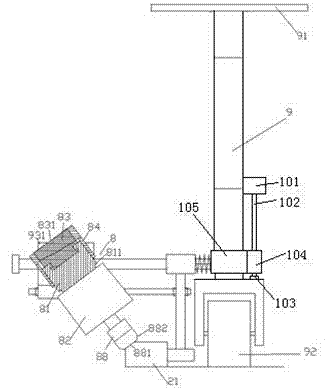

Hydraulically adjustable garden road edge trimming device and method of use thereof

ActiveCN104816215BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesGrinding/polishing safety devicesEngineeringGrinding wheel

Provided are a hydraulically adjusted garden road trimming device and an application method thereof. The device is used for performing chamfering trimming on the edge of the top of the outer side of a kerb (21). The hydraulically adjusted garden road trimming device comprises a machine frame (9), walking wheels (92) at the lower end of the machine frame (9) and a walking pushing handle (91) arranged at the upper end of the machine frame (9). A sleeve part (104) matched with the machine frame (9) to slide up and down is arranged on the machine frame (9) above the walking wheels (92), and a horizontal bearing rod (93) is fixedly arranged on one side of the sleeve part (104) close to the kerb (21). A guiding wheel sliding sleeve (951) and a trimming grinding wheel module sliding sleeve (931) are sequentially slidably borne on the horizontal bearing rod (93) from inside to outside, and the cross section of the horizontal bearing rod (93) is square so as to prevent the guiding wheel sliding sleeve (951) and the trimming grinding wheel module sliding sleeve (931) from rotating on the horizontal bearing rod (93).

Owner:嘉兴笼列电子商务有限公司

Garden road edge trimming device with air pressure adjustment and using method thereof

ActiveCN104846724BGuaranteed aestheticsEffective chamfer grindingEdge grinding machinesRoads maintainenceEngineeringAtmospheric pressure

The invention relates to an air pressure regulation garden road trimming device and a using method thereof. The device is used for carrying out chamfer trimming on the edge of the top outside a curbstone (21) and comprises a rack (9), a traveling wheel (92) arranged at the lower end of the rack (9) and a traveling push handle (91) arranged at the upper end of the rack (9); a sleeve part (104) matched with the rack (9) to slide up and down is arranged on the rack (9) and above the traveling wheel (92); a transverse bearing rod (93) is fixedly arranged at one side, which is close to the curbstone (21), of the sleeve part (104); a guide wheel sliding sleeve (951) and a trimming grinding wheel assembly sliding sleeve (931) are sequentially borne in a sliding manner on the transverse bearing rod (93) from inside to outside and the cross section of the transverse bearing rod (93) is of a square shape so as to prevent the guide wheel sliding sleeve (951) and the trimming grinding wheel assembly sliding sleeve (931) from rotating on the transverse bearing rod (93).

Owner:浙江天地环境建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com