Chamfering and grinding device for disc-cutting edge

A technology of disc shearing and chamfering, which is applied in the direction of grinding drive device, grinding workpiece support, grinding machine tool parts, etc. Problems such as short service life and high labor intensity of workers can achieve the effects of improving utilization rate and production efficiency, reducing processing costs, and simplifying assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

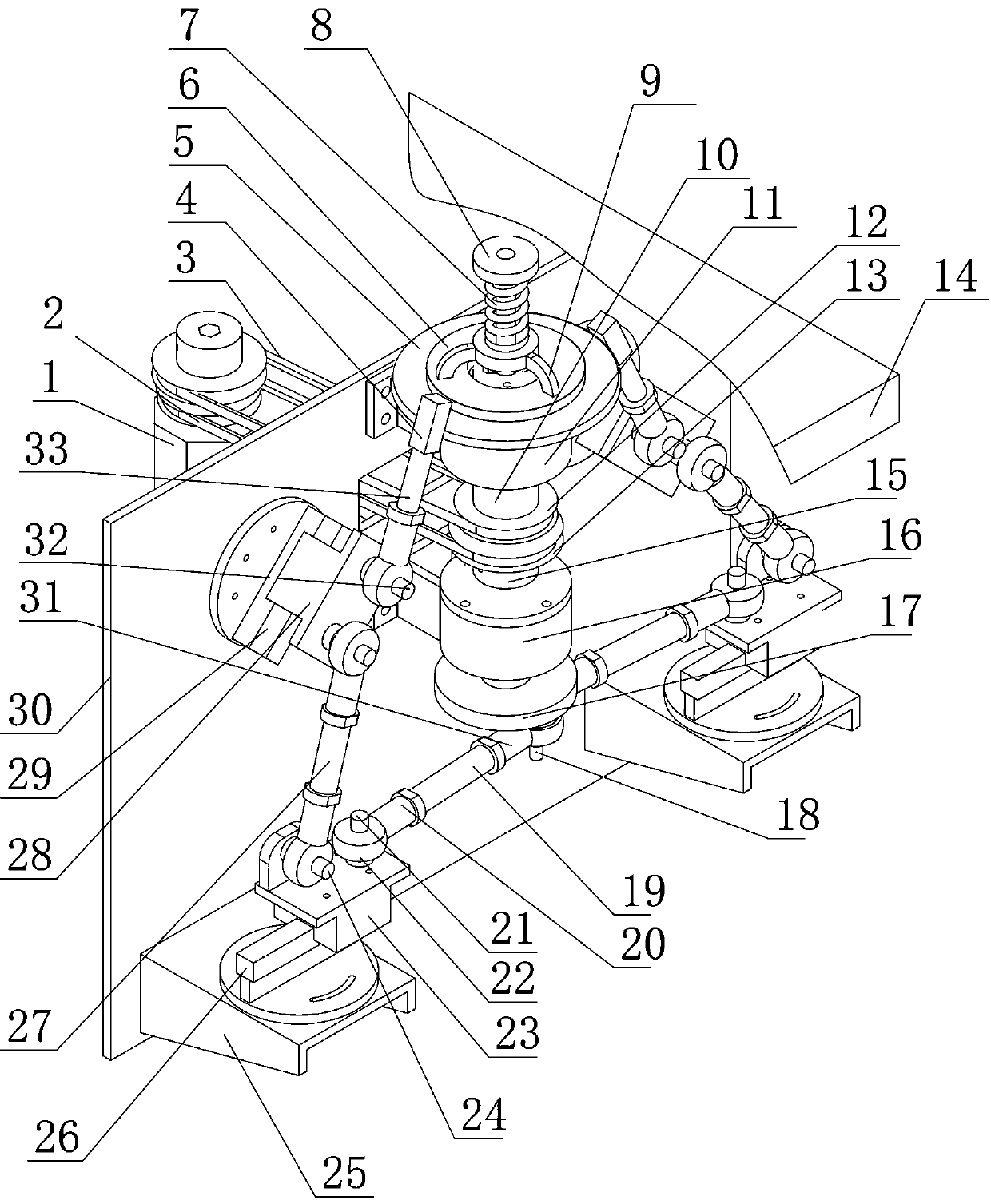

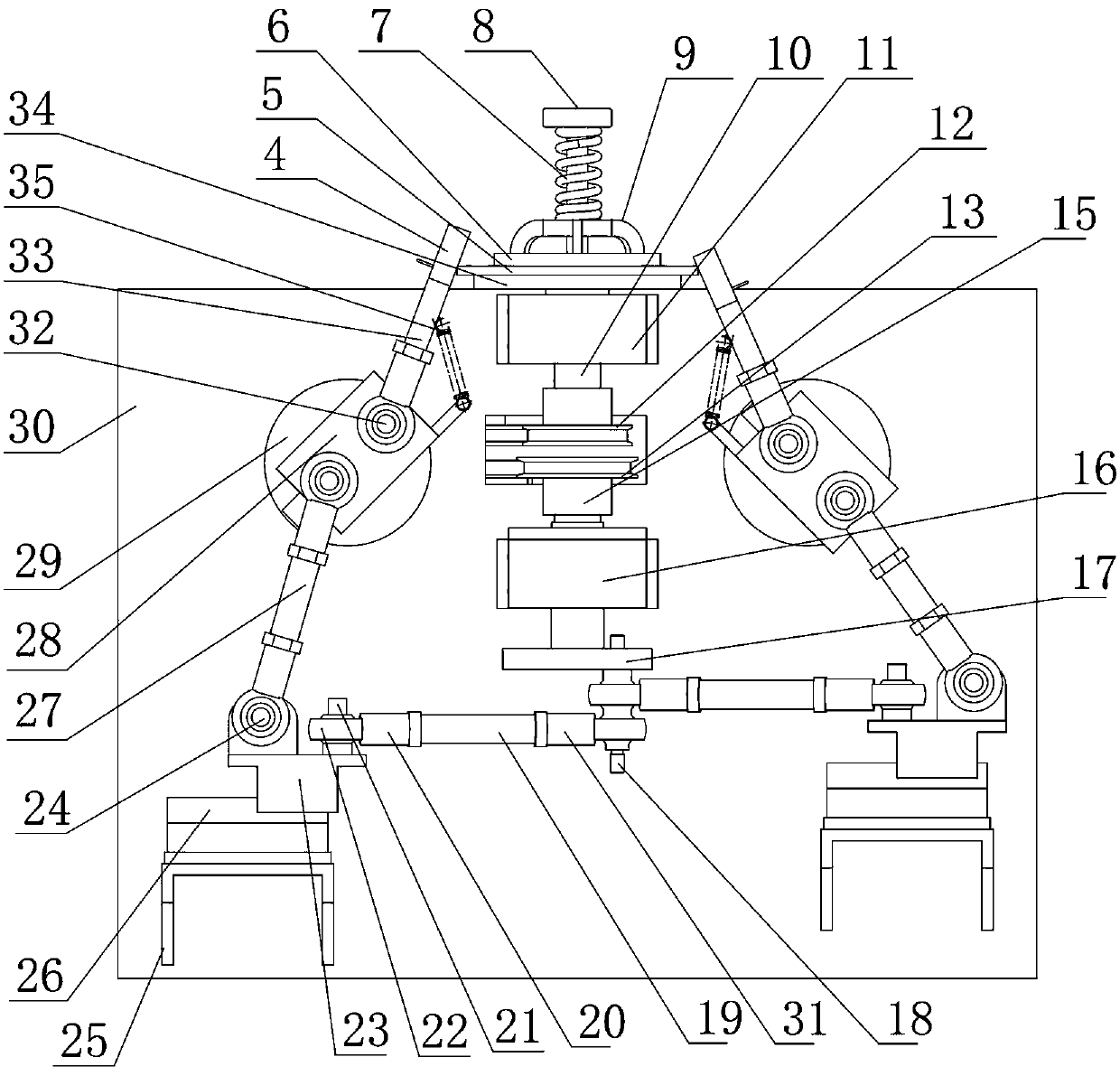

[0017] Such as figure 1 , 2 , as shown, the disc shear edge chamfering grinding device of the present invention includes a support stand 14, a support stand 30 fixed below the support stand, and a driving device on one side of the support stand is arranged here The rotary motion transmission device of the cutting blade and the reciprocating linear motion transmission device of the grinding head on the other side of the supporting vertical plate are connected with the driving device, so The above-mentioned shearing blade rotary motion transmission device is composed of the upper transmission wheel 12 connected to the driving device, the upper transmission shaft 10 fixedly connected with this upper transmission wheel, and the shearing blade tray 34 fixedly connected with this upper transmission shaft, passing through The upper transmission shaft is arranged on the cutting edge piece 5 above the cutting edge tray, and the gland assembly that fixes the cutting edge piece on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com