A method for strengthening the bottom plate of working face by grouting at the top of Austrian ash

A technology of grouting reinforcement and working face, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems that cannot satisfy the safety production in the deep part of the mining area, and achieve the effect of increasing production and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

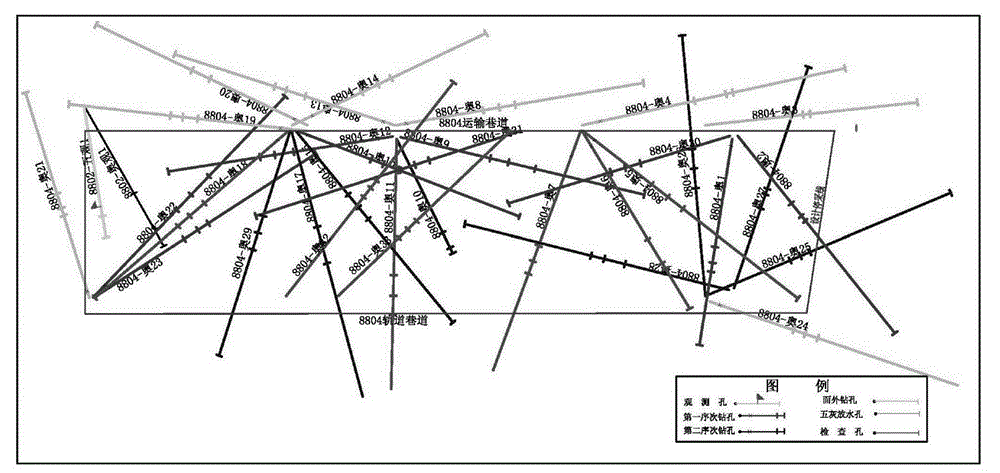

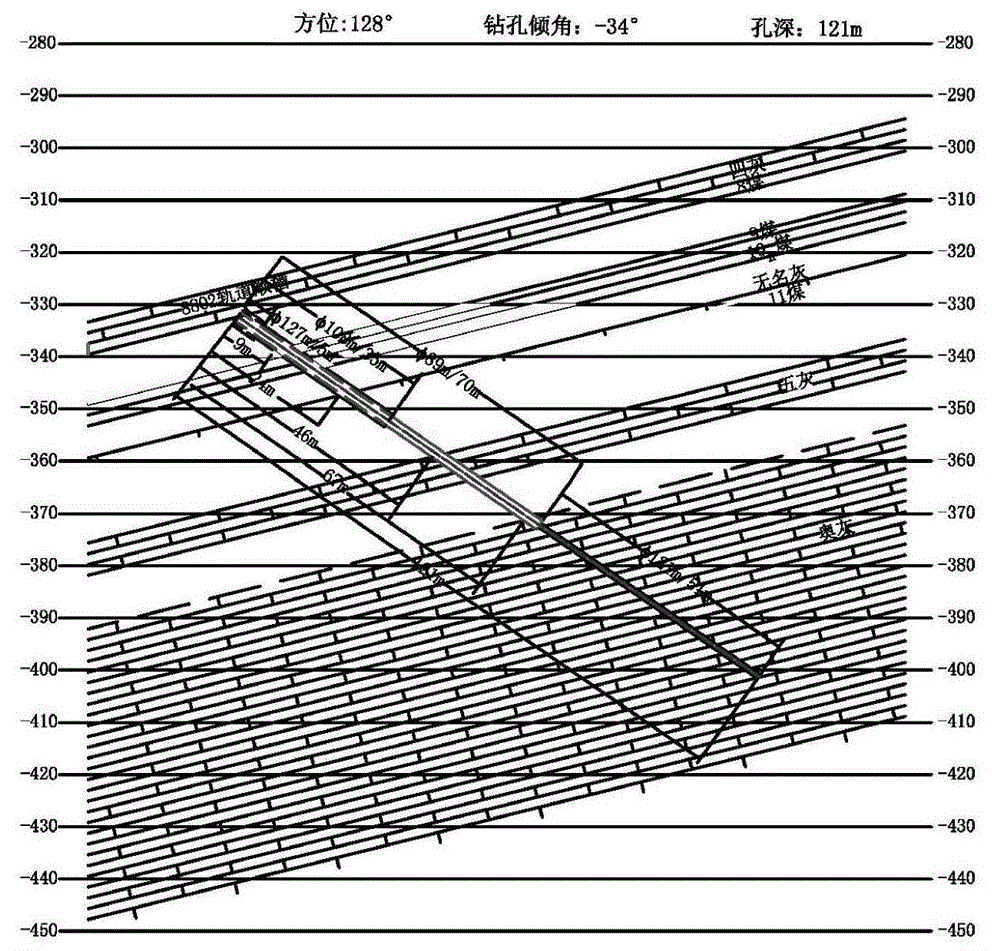

[0027] In this embodiment, the working face is transformed by grouting at the top of Austrian ash in a certain mining area, and the specific process is as follows:

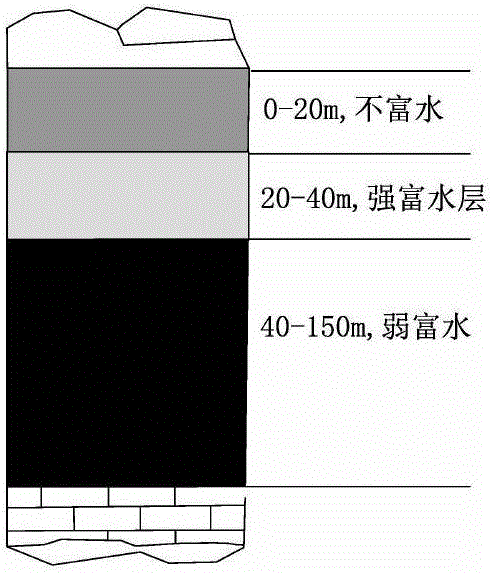

[0028] (1) Feasibility analysis of grouting at the top of Austrian ash: the Austrian ash aquifer is not an aquifer as traditionally considered, but a multi-layered aquifer with the characteristics of strata control, structure control, and rhythm. The aquifer sections are relatively independent and interrelated. The top of the Ordovician limestone mainly refers to the upper part of the Fengfeng Formation of the Middle Ordovician limestone, and the thickness of the upper part of the Fengfeng Formation is 154.68m. There are three layers, such as figure 1 Shown:

[0029] The upper part (0-20m) of the Austrian ash top is a relatively weak water-bearing layer section, and the range of 0-10m is a relatively water-resistant layer section, forming the "capping layer" required for the grouting reconstruction of the Austria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com