Separated shared pump base of multistage centrifugal pump

A centrifugal pump and separate technology, which is applied to parts, pumps, pump components, etc. of pumping devices for elastic fluids, can solve the problems of inconvenient disassembly and inconvenient use of centrifugal pumps, and achieve timely maintenance and cost savings , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

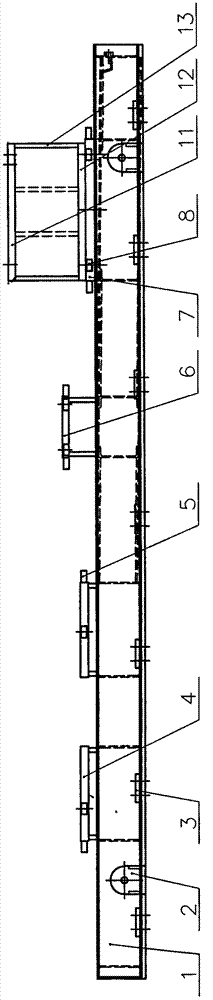

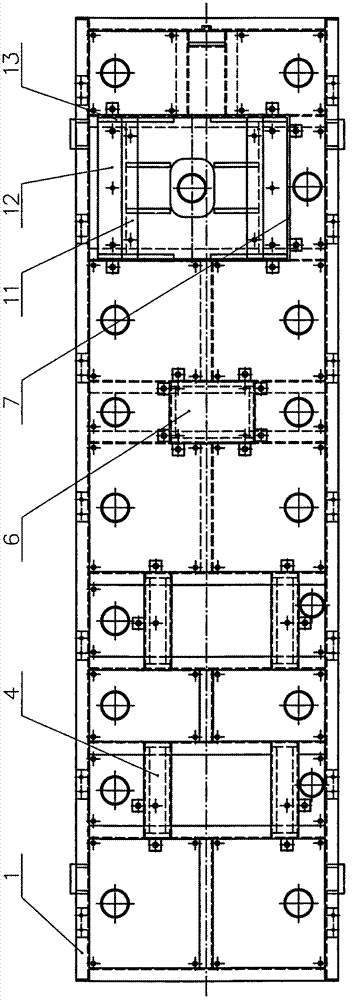

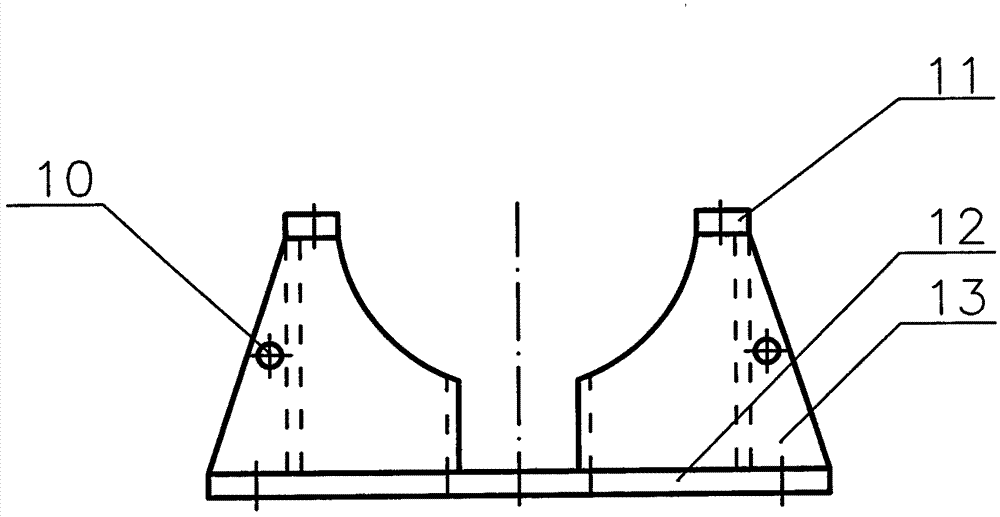

[0011] refer to Figure 1 to Figure 4 As shown, the separate shared pump seat of the multistage centrifugal pump of the present invention includes a chassis 1 (which is a heavy-duty channel steel joint welding method, with a lifting ring 2 and a spacer 3), a motor support plate 4 (and a motor adjustment block 5 ), the transmission equipment support plate 6, the pump base support plate 7 (and the pump base adjustment block 8), the base plate 12 (with detachability) is equipped with the fastener 9 (bolt) on the pump base support plate 7 On the base plate 12, transverse ribs 13 and longitudinal ribs 14 (several strips) are installed, and a pump support block 11 is installed on the top of the transverse ribs 13. The transverse ribs 13 are several and distributed on both sides of the base plate 12, between the transverse ribs and the pump support block are used to support and place the centrifugal pump (its pump body); Lifting holes 10 are provided on the side surfaces of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com