Composite pull rod suspension device for vibrating feeding trough

A suspension device and feeding trough technology, applied in lighting and heating equipment, furnaces, furnace components, etc., can solve problems such as restricting the production efficiency of CONSTEEL electric furnaces, large maintenance of suspension devices, and easy breakage of tie rods, reducing manufacturing and installation. Accuracy requirements, increased life, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

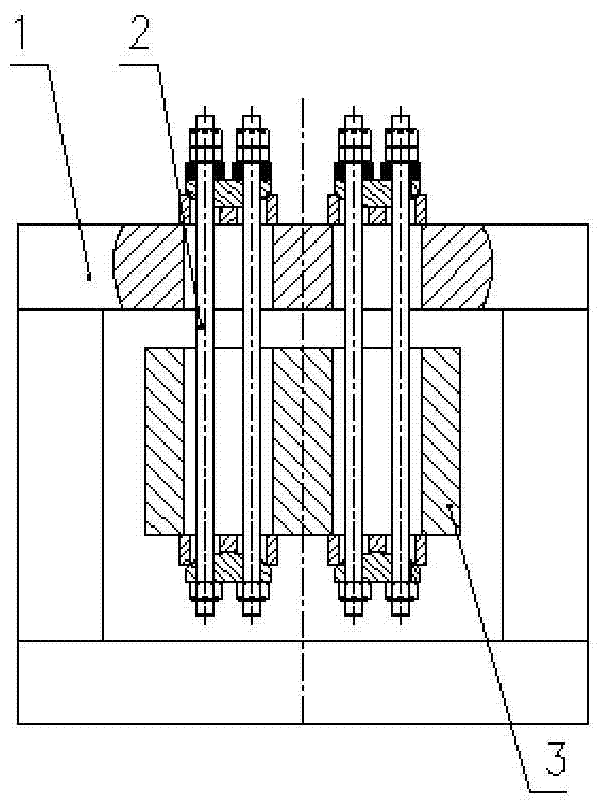

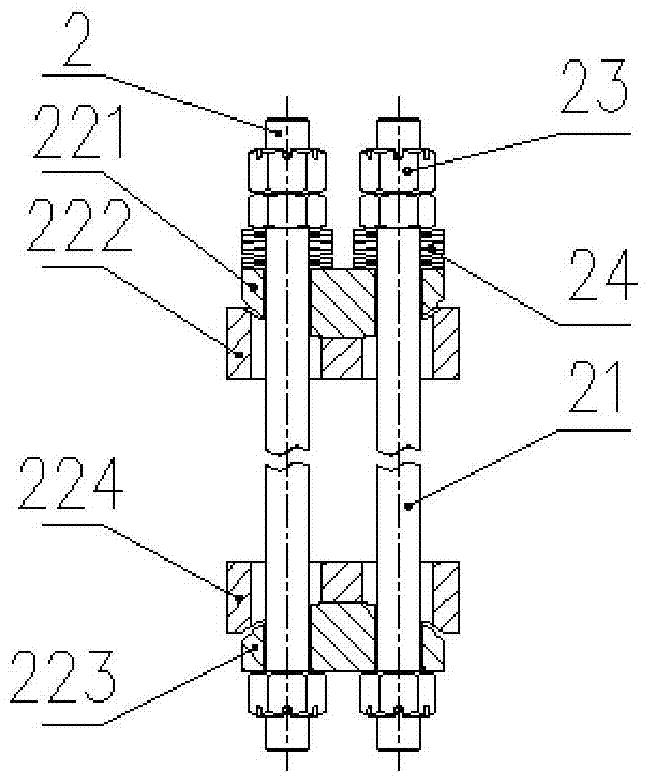

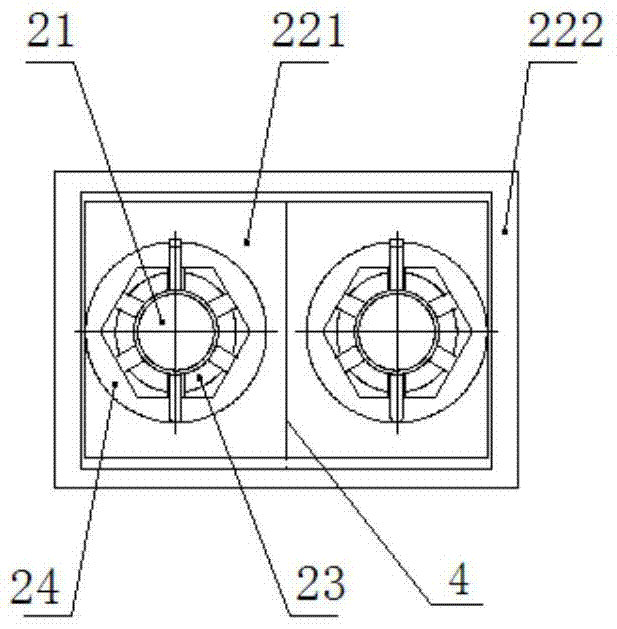

[0025] Such as figure 1 , figure 2 , image 3 As shown, a composite tie rod suspension device for a vibrating feed tank includes a support 1 and a composite pull rod swing mechanism 2 arranged on the support 1; the mechanism 2 includes a pull rod 21 for connecting the feed tank 3 and the support 1 And cooperate with pull rod 21 to lock the briquetting group of feeding trough 3 and support 1; said pull rod 21 is at least two, and with respect to the contact line 4 of briquetting group (if it is surface contact, then refers to the contact surface length direction The geometric center line) is symmetrically arranged; the briquetting group includes an upper briquetting group and a lower briquetting group, and the tie rod 21 runs through the upper briquetting group, the support 1, the feeding trough 3 and the lower briquetting group in sequence, and Its two ends are locked and fixed by nuts 23; the upper pressing block group includes pressing blocks a221 and b222, the pressing b...

Embodiment 2

[0031] Such as Figure 4 As shown, a composite tie rod suspension device for a vibrating feeding tank includes four pull rods 21, and is arranged symmetrically with respect to the contact line 4 of the briquetting block group. It can maintain normal work for a period of time, reduce the probability of sudden failure and shutdown, and ensure normal production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com