A leak-proof high-viscosity fluid mixing reactor

A fluid mixing and reactor technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. Uneven cooling and other problems, to achieve the effect of overcoming easy breakage, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing, so that understand the present invention better.

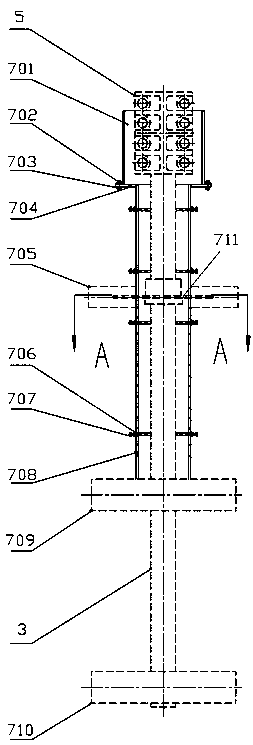

[0034] A leak-proof high-viscosity fluid mixing reactor of the present invention includes a power device 1, a power transmission device 2, a stirring shaft 3, a coupling 5 and a sealing device 6. The connection relationship between these components belongs to the prior art and is not in This is repeated.

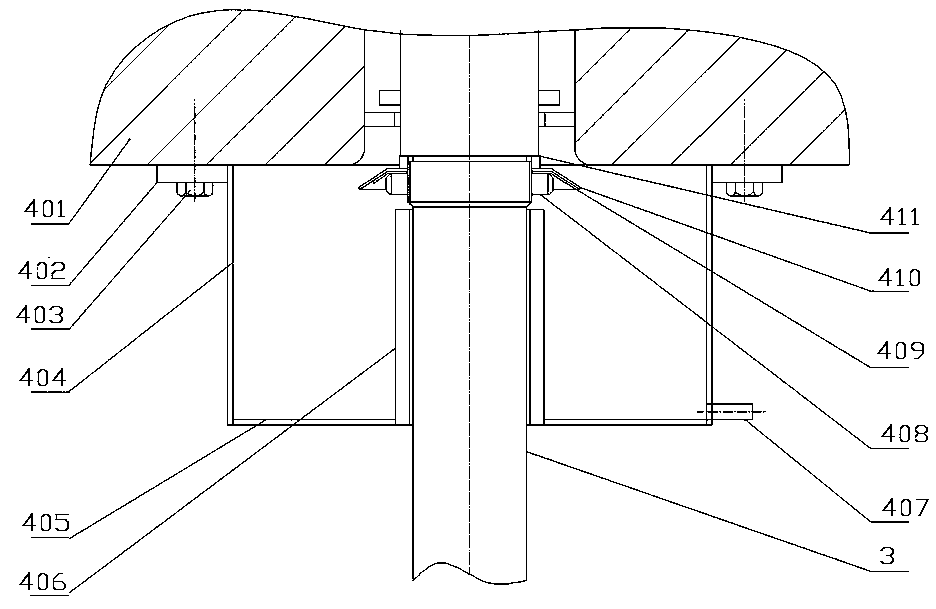

[0035] The power of the power device 1 is transmitted to the stirring shaft 3 through the power transmission device 2, and an oil leakage prevention structure 4 is arranged on the stirring shaft in the reactor.

[0036] The oil leakage prevention structure 4 includes an oil retaining part installed on the stirring shaft 3 inside the reaction kettle and an oil receiving part for accommodating grease. In this embodiment, the oil retaining parts include an oil retaining umbrella 410, a briquetting block 411, a stop washer 409...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com